Would you reduce preload on all of them before replacing them? I read an old post by bison where he ran very little preload on cc 885s with little noise until after a pass. My noise is mostly at idle

My stuff,

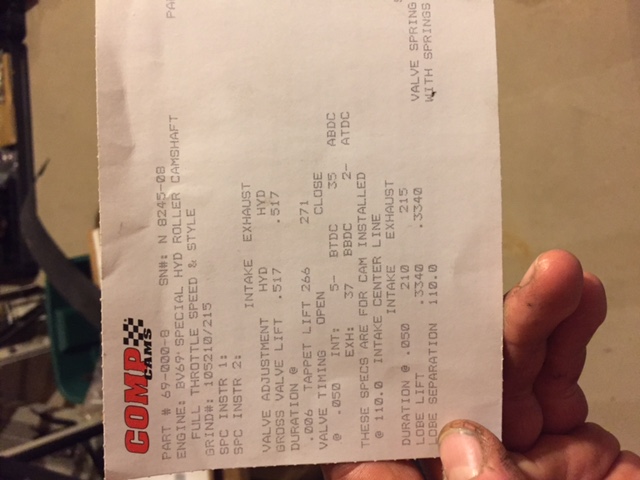

CC 210/215 & cc lifters

Harlend sharp 1.6 rockers, 1/2 turn preload

Oil psi 20@idle

My stuff,

CC 210/215 & cc lifters

Harlend sharp 1.6 rockers, 1/2 turn preload

Oil psi 20@idle

Last edited: