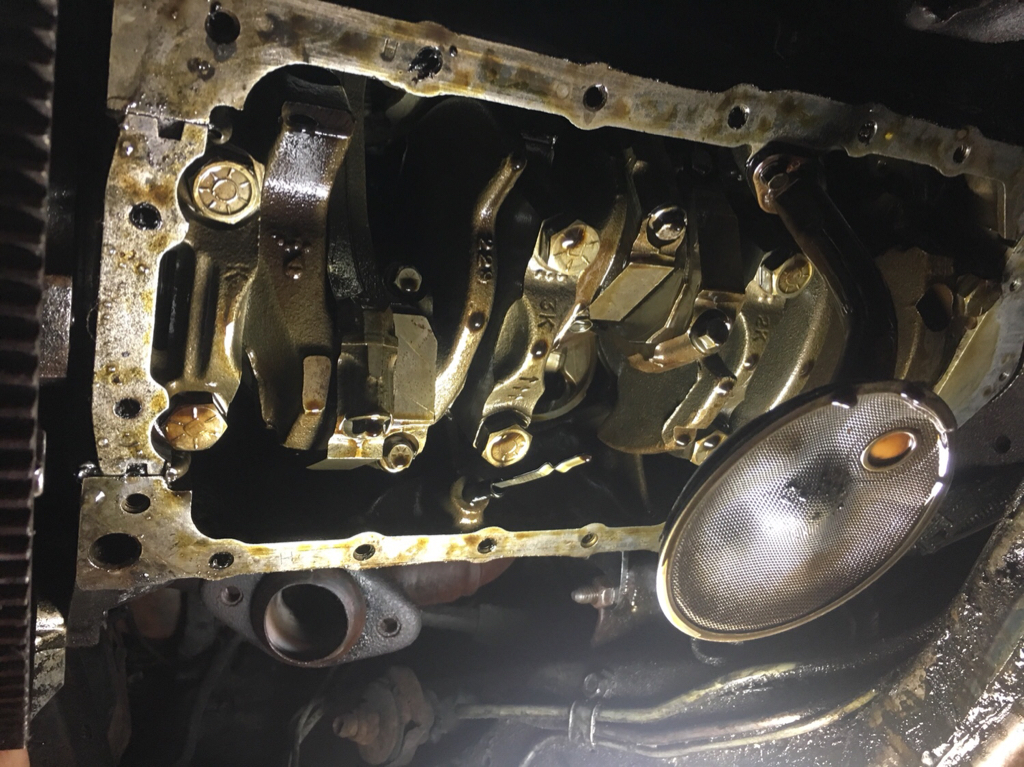

I have performed several searches and can’t find any info on this tag. I have the engine apart because of a blown head gasket. Tag was attached to the front of the block. I pulled the pan and the crank is turned .010 and 60 stamped on the pistons. Crank doesn’t bother me but if the bore is .060 that’s a bit much for a turbo 109. Does anyone recognize this tag?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk