You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need help on choosing the right turbo size

- Thread starter CS99

- Start date

- Joined

- May 26, 2001

CS99. what fuel will you be using and what boost levels are you comfortable with?

With a 270 ci setup and the ability to modify your headers to suit, this opens up a lot of possibilities. But, being those headers started life as 3 bolt headers, this will put the turbo in the stock location no matter which flange you decide on using. Clearances will come into play at this point if you go with a larger turbo than say a normal sized T4 chassis turbo. Once you get out of the T4 size turbos and move into mid size turbo land, the CHRA and housings (both compressor cover and turbine housing) get larger. This dramatically affects everything that surrounds the turbo, as well as needing a custom downpipe made to fit.

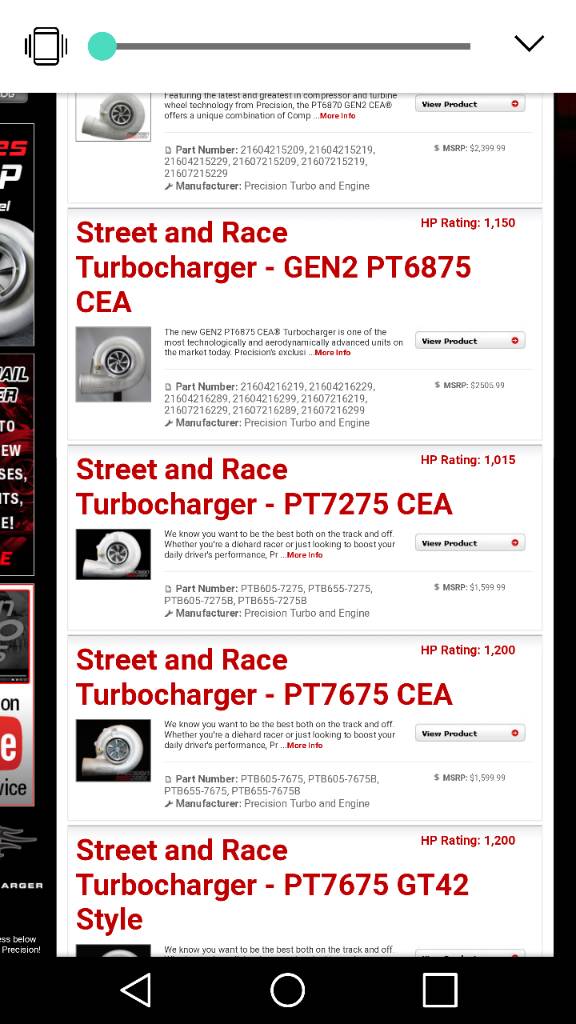

If you want a turbo that will pretty much bolt on, with only changing the header inlet flange and making a custom downpipe, I would definitely go with a GEN2 PT7675 CEA turbo with their investment casted stainless steel all v-band turbine housing in .96 a/r. This would give you the quickest spool up, easiest to install, and the foot print would be good to go with all of the surrounding accessories and plumbing without too much hassle. Going with the all v-band turbine housing gives you the smoothest flow from the cylinder head, to the turbine wheel. Mainly because everything that leaves the heads stay in a perfect circular tube with very little turbulance in between. Ala, superior aerodynamic flow. The T4 flange transition definitely has turbulance as the exhaust has to transition from round, to rectangular, then back to round before hitting the turbine wheel. One thing to remember about any H size compressor cover equipped T4 turbo is, the rubber S hose off the stock style water pump neck will rub on the compressor cover, but it's no biggie. You would need to run either C-16, E85, or 93 pump with a lot of dual nozzle alky goodness, plus a lot of boost (35-40psi) in order to make 1000 rwhp with this turbo. You also could run into back pressure issues when you start getting the boost that high. It would be a ton of fun on the street and with the CI that size, you shouldn't need a lot of stall to spool it. But, just know this. If you go this route, this is the largest true T4 size turbo that requires the least amount of custom fab work to fit. So you would pretty much be land locked with this turbo and the power it makes. Also, you would need to redo everything, if you upgrade to a mid frame turbo in the future. Even if you went with an old school PT88 with the cantalope T4 turbine housing. And seeing as not many Buick guys/girls run this turbo when trying to make 1000-1200 rwhp, you would be limited on the max rwhp it can make.

https://www.precisionturbo.net/Stre...t-and-Race-Turbocharger---GEN2-PT7675-CEA/606

Now, if fabrication and non stock location is not an issue, IE: you'll make everything around it fit somehow, and you want a turbo that will definitely make the power without having to run 40psi to do it, I would look at a PT8685 Gen 2 CEA with a T4 divided housing in 1.12 a/r to start. Get the 1.28 a/r housing for future power, aka maxing out the turbo. This one would work well with your combo and definitely make the power. But, due to the larger Sportsman style compressor cover, and the larger 4 5/8" downpipe flange, a 4 - 4.5" downpipe will be required. And even though it is dual ball bearing, the stall speed requirements will be higher for quick spool up.

https://www.precisionturbo.net/Stre...t-and-Race-Turbocharger---PT8685-GEN2-CEA/561

Now, these are just the PTE turbos I would recommend if I had your combo and goals. There are other Borg Warner and Garrett turbos out there that will make the power. Most of them are of the mid frame chassis turbos. Most of the TSO racers that are at this power level, either run a PT4788 turbo, or a Pro Mod 88. The serious guys in that class are making over 1400 rwhp. Those combos can turn the boost down and make 1000 rwhp all day.

One things for sure, your goals of 1000 rwhp on your combo are definitely not cheap, nor easy.

Definitely keep us posted and hope some of this helps.

-Patrick-

With a 270 ci setup and the ability to modify your headers to suit, this opens up a lot of possibilities. But, being those headers started life as 3 bolt headers, this will put the turbo in the stock location no matter which flange you decide on using. Clearances will come into play at this point if you go with a larger turbo than say a normal sized T4 chassis turbo. Once you get out of the T4 size turbos and move into mid size turbo land, the CHRA and housings (both compressor cover and turbine housing) get larger. This dramatically affects everything that surrounds the turbo, as well as needing a custom downpipe made to fit.

If you want a turbo that will pretty much bolt on, with only changing the header inlet flange and making a custom downpipe, I would definitely go with a GEN2 PT7675 CEA turbo with their investment casted stainless steel all v-band turbine housing in .96 a/r. This would give you the quickest spool up, easiest to install, and the foot print would be good to go with all of the surrounding accessories and plumbing without too much hassle. Going with the all v-band turbine housing gives you the smoothest flow from the cylinder head, to the turbine wheel. Mainly because everything that leaves the heads stay in a perfect circular tube with very little turbulance in between. Ala, superior aerodynamic flow. The T4 flange transition definitely has turbulance as the exhaust has to transition from round, to rectangular, then back to round before hitting the turbine wheel. One thing to remember about any H size compressor cover equipped T4 turbo is, the rubber S hose off the stock style water pump neck will rub on the compressor cover, but it's no biggie. You would need to run either C-16, E85, or 93 pump with a lot of dual nozzle alky goodness, plus a lot of boost (35-40psi) in order to make 1000 rwhp with this turbo. You also could run into back pressure issues when you start getting the boost that high. It would be a ton of fun on the street and with the CI that size, you shouldn't need a lot of stall to spool it. But, just know this. If you go this route, this is the largest true T4 size turbo that requires the least amount of custom fab work to fit. So you would pretty much be land locked with this turbo and the power it makes. Also, you would need to redo everything, if you upgrade to a mid frame turbo in the future. Even if you went with an old school PT88 with the cantalope T4 turbine housing. And seeing as not many Buick guys/girls run this turbo when trying to make 1000-1200 rwhp, you would be limited on the max rwhp it can make.

https://www.precisionturbo.net/Stre...t-and-Race-Turbocharger---GEN2-PT7675-CEA/606

Now, if fabrication and non stock location is not an issue, IE: you'll make everything around it fit somehow, and you want a turbo that will definitely make the power without having to run 40psi to do it, I would look at a PT8685 Gen 2 CEA with a T4 divided housing in 1.12 a/r to start. Get the 1.28 a/r housing for future power, aka maxing out the turbo. This one would work well with your combo and definitely make the power. But, due to the larger Sportsman style compressor cover, and the larger 4 5/8" downpipe flange, a 4 - 4.5" downpipe will be required. And even though it is dual ball bearing, the stall speed requirements will be higher for quick spool up.

https://www.precisionturbo.net/Stre...t-and-Race-Turbocharger---PT8685-GEN2-CEA/561

Now, these are just the PTE turbos I would recommend if I had your combo and goals. There are other Borg Warner and Garrett turbos out there that will make the power. Most of them are of the mid frame chassis turbos. Most of the TSO racers that are at this power level, either run a PT4788 turbo, or a Pro Mod 88. The serious guys in that class are making over 1400 rwhp. Those combos can turn the boost down and make 1000 rwhp all day.

One things for sure, your goals of 1000 rwhp on your combo are definitely not cheap, nor easy.

Definitely keep us posted and hope some of this helps.

-Patrick-

billet bb 69mm,3 or 4 bolt.900 to 1000 rwhp

Sent from my VS987 using Tapatalk

- Joined

- May 26, 2001

For your CI size and power goal, you definitely want a .96 in any turbine housing you choose, whether it's T4 single throat, divided, or all v-band. Ultimately, the turbine wheel size has a lot of affect on hp potential and back pressure. Typically when you read 4 digit turbo p/n's, the turbine wheel is the second set of digits. Ex: 6870 has a PTE proprietary 70mm turbine wheel. 6875 uses a 75mm turbine wheel. Another thing you gotta keep in mind, the hp ratings you see on turbo websites, is the flywheel hp rating, not rear wheel. Meaning, if you want to make 1000 rear wheel hp, you do not select a turbo that is rated to support 1000, 1100, or even 1150. It won't make it. This is mainly due to drive train losses and the potential for back pressure issues at extremely high boost levels. However, there are a lot more variables that come in to play as well when pushing for 1000 rwhp. Another thing, some turbo companies intentionally "pad" the hp ratings, so the customer will be very happy with their end results. But in my many years of working for PTE, I always slightly over spec'd/sized the turbo, as I didn't want customers to be ticked off and disappointed after running it. Hence why I recommended the turbos above that I did. I would classify the 6870 and the 6875 as powerful street turbos, but not something I would absolutely 100% count on, to be able to support 1000 rear wheel hp on a 270 ci v6 Buick. And the last thing, your goals will require a relatively pricey turbo, no matter who you get it from. The last thing you want to do, is get a turbo that is way too small for your goals and try to force it to make your power goal. That is a recipe for disaster.

-Patrick-

-Patrick-

- Joined

- May 26, 2001

Is the physical size of the 68/75 with .96 housing and vband inlet much larger then the 67/68 with .85 housing?

Sent from my VS987 using Tapatalk

Both of those turbos when spec'd with the same compressor covers are physically the same size, except for one thing. That being the installed height differences between the two turbine housings. Meaning, when the T4 housing is on it, the height could be slightly different if you swap on the all v-band housing.

You would need to call PTE and ask them for specific measurement differences between the two housings to know for certain. I have not put my hands on one of their new Investement cast SS all v-band housings, nor have I seen one on a car. Maybe someone who has run this new housing on a Buick will chime in.

Cough cough Otto, cough.

you put a 76/75 on this combo and there is a real good chance its going to be lazy especially on the street.if its a track only car leaving on the tbrake different.you really need to look at the kind of shift rpm you will be able to have and the kind of rpms the turbo of choice will need.I have a TA motor, 270 ci. 220/220 540 lift cam. 16 vane PTC non loc, Champion race intake, TA aluminum heads with 202 valves. 9 to 1 compression. Should I go 4 bolt? and what size?

chris kirk

Active Member

- Joined

- Jun 1, 2013

I have a TA motor, 270 ci. 220/220 540 lift cam. 16 vane PTC non loc, Champion race intake, TA aluminum heads with 202 valves. 9 to 1 compression. Should I go 4 bolt? and what size?

If you're not racing in a class, IMO, I think your nuts not to use a v-band or 4-bolt. I know, I know......there's plenty of people who have gone fast on 3-bolts, but why if you don't have too. Also, there are some options (granted you have a good welder) for modifying your headers for turbo placement. Just have to figure out where you want your turbo.

I know I'm gonna get a lotta shit for this, (as I always do) for it always gets the Preshitcision people all assed up, (and everyone already knows what an asshole I am so I guess it doesn't matter) but there are other options which are much better then what you're considering. Kinda funny that you mention the 6870. At one point there were 3 or 4 of them for sale in the "Parts for sale" section. Gee, I wonder why..... Talk to Reed at Works Turbo he'll get you straight. Or, Forced Inductions.

Want to know how it runs. Good luck.

Similar threads

- Replies

- 2

- Views

- 788

- Replies

- 0

- Views

- 465

- Replies

- 0

- Views

- 2K