GNVYUS 1

Well-Known Member

- Joined

- Dec 15, 2002

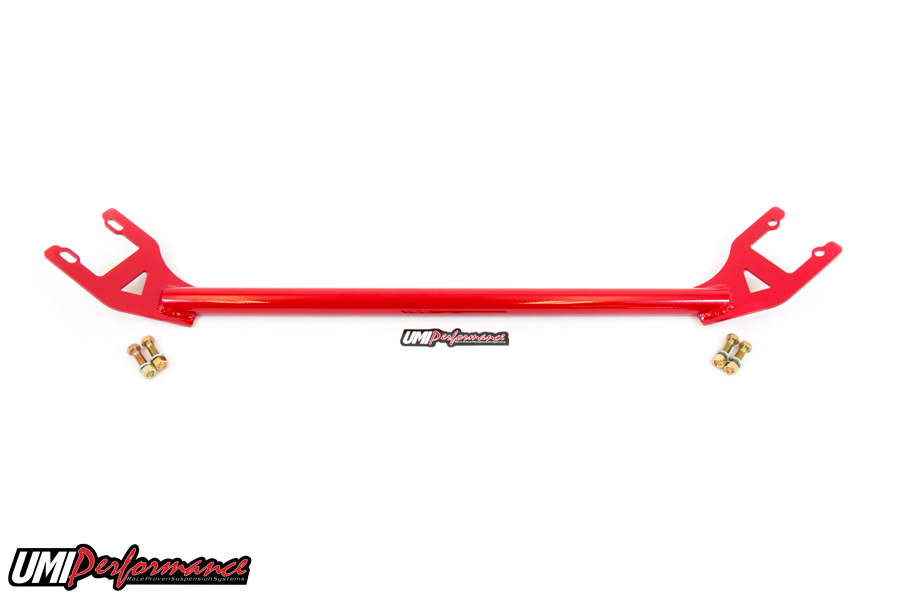

Picture is of Ridetech coilovers with their mounting bracket off the rear end. The Viking and UMI bracket looks like it would have the same interference.

There's no room for a 325/50r15 here with coil overs, even if you had a BS of 5.5" let alone greater than 5.5". The bracket is designed with the full rear frame in place, understandable.

Frame notchers, big wide tires, coilovers, what did you do to stuff them in? Anyone do this?

I'm gonna have the local, high end fabricator, design, weld, install, scan and sell this bracket for us. Then my other buds with sell a Viking CO Frame Notch package for us with these new brackets.

Brackets getting made hopefully soon so I can send the wheels out for widening.

Starting this thread for start to finish progress on this and to have a solution for us current and future frame notchers. This isn't going to be cheap either, Jesus it never stops. LOL

There's no room for a 325/50r15 here with coil overs, even if you had a BS of 5.5" let alone greater than 5.5". The bracket is designed with the full rear frame in place, understandable.

Frame notchers, big wide tires, coilovers, what did you do to stuff them in? Anyone do this?

I'm gonna have the local, high end fabricator, design, weld, install, scan and sell this bracket for us. Then my other buds with sell a Viking CO Frame Notch package for us with these new brackets.

Brackets getting made hopefully soon so I can send the wheels out for widening.

Starting this thread for start to finish progress on this and to have a solution for us current and future frame notchers. This isn't going to be cheap either, Jesus it never stops. LOL