Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

I looked through my throttle body the other day and noticed that it needed some porting since I have an Acuufab TB with an OEM dog house. There was an edge around the entire TB (didnt take pics of that).

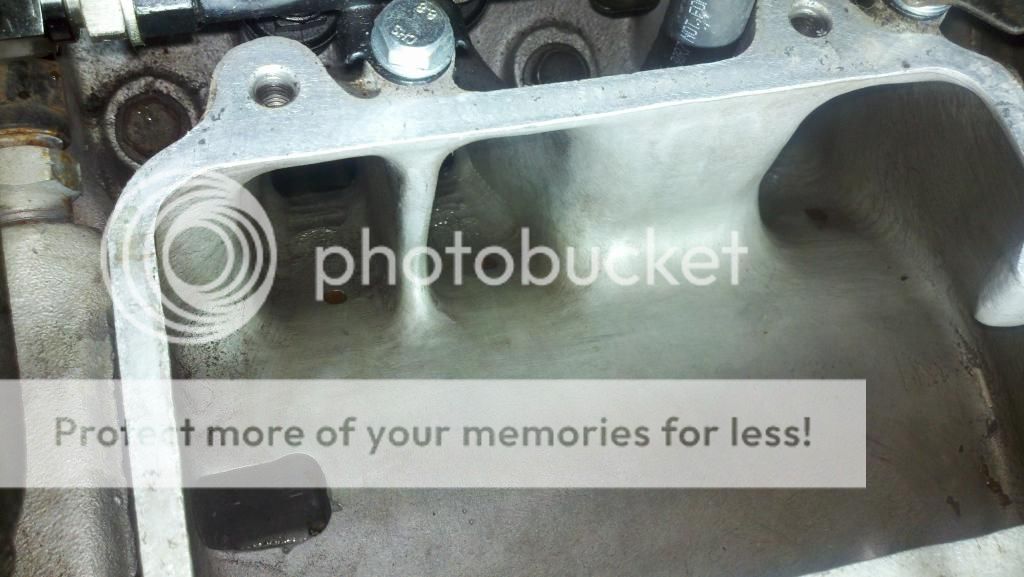

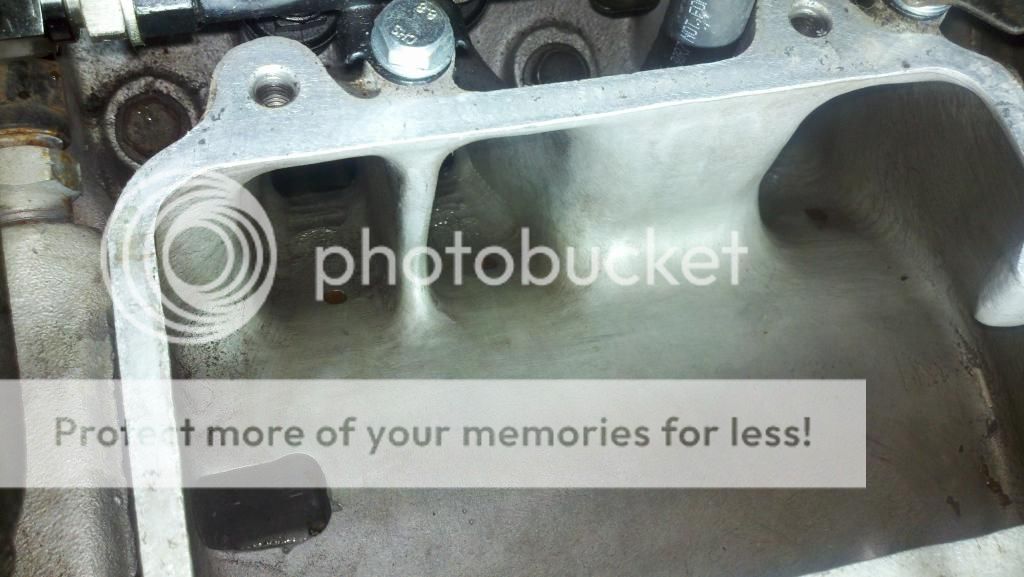

Now that I did that I noticed some things when I had the doghouse off. The lower intake was extensively ported (so were the heads from what I can see into the intake chambers) Maybe a bit on the severe side. Im no expert so Im not sure if they did go too far. I found 1 hole in each intake tube that are filled with what appears to be epoxy. Any info on this? Is my lower intake junk? I have a welder so I could weld it but I would have to buy the specific gun to do it. I tried to get a picture of the porting in the heads but all the pics cam out blurry.

Now that I did that I noticed some things when I had the doghouse off. The lower intake was extensively ported (so were the heads from what I can see into the intake chambers) Maybe a bit on the severe side. Im no expert so Im not sure if they did go too far. I found 1 hole in each intake tube that are filled with what appears to be epoxy. Any info on this? Is my lower intake junk? I have a welder so I could weld it but I would have to buy the specific gun to do it. I tried to get a picture of the porting in the heads but all the pics cam out blurry.