FP Regulator Ignorance

- Thread starter BFlat

- Start date

Welcome!

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

John Larkin

Sublime Master of Turbology

- Joined

- May 25, 2001

- Messages

- 5,013

Its the boost line when accelerating. It increases the fuel pressure, to say it simply.

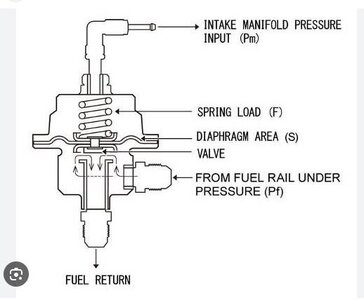

We have a direct operating back pressure regulator. There's a diaphragm inside with a spring pushing it down against a seat. The high fuel pressure pushes up on the diaphragm and seat from the bottom to overcome the spring pressure until an intermediate "regulated" pressure is reached upstream of the seat feeding our injectors. Most regulators (air compressors and general industry) sense downstream pressure and maintain a constant pressure minus droop. But in our case, it senses upstream pressure from the fuel pump, and has a pressure assisted diaphragm from the engine vacuum/boost. When you create boost, it provides additional load to the diaphragm to close off and reduce the fuel return, and increases pressure upstream to feed the injectors. That's why the fuel pressure in our cars is not static, and changes with vacuum and boost.

Last edited:

Most normally aspirated cars use vacuum as well. The vacuum unloads the diaphragm, opening the orifice causing more fuel to go to the tank. When you floor the gas, the vacuum drops, the drop in vacuum means atmospheric pressure on top of the diaphragm is rising, it helps load the diaphragm along with the spring, which closes off the orifice feeding the return line, and raises the fuel pressure upstream just like boost, just not as much.Thanks! So if the car doesn’t have a turbo there’s no vacuum line to the regulator - right?

Here's a good diagram. The fuel pressure is pushing up against the spring and manifold pressure to open the regulator, and that opening between the orifice and seat determines how much fuel returns to the tank. Under vacuum, alot of fuel is flowing back to the tank. Under full load, the regulator likely is fully closed with no return, and the injectors use all the fuel, then you see your duty cycle start to spike and fuel pressure drop.

Attachments

1986 Buick GX1

GX1 #001 [The One and Only]

- Joined

- Apr 24, 2015

- Messages

- 2,566

Essentially, the spring has a set pressure that you adjust to 43psi.

Vacuum sucks on the diaphragm making the spring weaker, lowering fuel pressure.

When you floor an N/A car the vacuum goes to 0, raising fuel press to 43psi. More power, more fuel.

When you floor a turbo car, the boost pushes on the diaphragm making the spring stronger, raising fuel pressure.

To maintain proper air fuel ratio it’s important to have 1 psi fuel pressure increase to 1 lb of boost and hoses in good condition with zip ties for higher boost levels.

EX: 43 psi base fuel pressure + 30lbs boost = 73 psi fuel pressure.

Some systems increase fuel flow by pulsing the injectors to hold them open longer.

We do it by increasing fuel pressure.

Vacuum sucks on the diaphragm making the spring weaker, lowering fuel pressure.

When you floor an N/A car the vacuum goes to 0, raising fuel press to 43psi. More power, more fuel.

When you floor a turbo car, the boost pushes on the diaphragm making the spring stronger, raising fuel pressure.

To maintain proper air fuel ratio it’s important to have 1 psi fuel pressure increase to 1 lb of boost and hoses in good condition with zip ties for higher boost levels.

EX: 43 psi base fuel pressure + 30lbs boost = 73 psi fuel pressure.

Some systems increase fuel flow by pulsing the injectors to hold them open longer.

We do it by increasing fuel pressure.

- Joined

- Aug 1, 2003

- Messages

- 9,836

Some systems increase fuel flow by pulsing the injectors to hold them open longer.

We do it by increasing fuel pressure.

this is incorrect , we do increase fuel flow with injector duty pulsing an injector from near 0% at idle to 100% as needed

the injectors have a rated flow at a set psi... x lbs fuel at 43psi

by setting the base static pressure to 43 psi and then reconnect the vac line which has vac and boost reference you are keeping injector flow at a given duty cycle constant regardless of boost or vac

increasing the pressure of the fuel in the injector linear with vac or boost of manifold keeps the flow the same , additional fuel is supplied by increasing the injector open time (duty cycle)

if you didnt raise the fuel pressure (which the regulator does) to overcome the the boost youd get less fuel flow through the tip of the injector

. as an extreme example is you have 43psi line off and you leave the line off and run boost at 43psi the manifold pressure of 43psi will cause zero flowthrough the injector and it wouldnt matter if injector were opened fully there would still be no flow

without a boost refenced regulator its like putting a ball inside a straw blowing in both ends, and expecting the ball to move ..the ball wont move if pressure on both ends is the same

1986 Buick GX1

GX1 #001 [The One and Only]

- Joined

- Apr 24, 2015

- Messages

- 2,566

this is incorrect , we do increase fuel flow with injector duty pulsing an injector from near 0% at idle to 100% as needed

the injectors have a rated flow at a set psi... x lbs fuel at 43psi

by setting the base static pressure to 43 psi and then reconnect the vac line which has vac and boost reference you are keeping injector flow at a given duty cycle constant regardless of boost or vac

increasing the pressure of the fuel in the injector linear with vac or boost of manifold keeps the flow the same , additional fuel is supplied by increasing the injector open time (duty cycle)

if you didnt raise the fuel pressure (which the regulator does) to overcome the the boost youd get less fuel flow through the tip of the injector

. as an extreme example is you have 43psi line off and you leave the line off and run boost at 43psi the manifold pressure of 43psi will cause zero flowthrough the injector and it wouldnt matter if injector were opened fully there would still be no flow

without a boost refenced regulator its like putting a ball inside a straw blowing in both ends, and expecting the ball to move ..the ball wont move if pressure on both ends is the same

Cool. Thank you.

Similar threads

Online statistics

- Members online

- 26

- Guests online

- 4,998

- Total visitors

- 5,024

Totals may include hidden visitors.