Rick the pool guy

Well-Known Member

- Joined

- Feb 7, 2017

- Messages

- 453

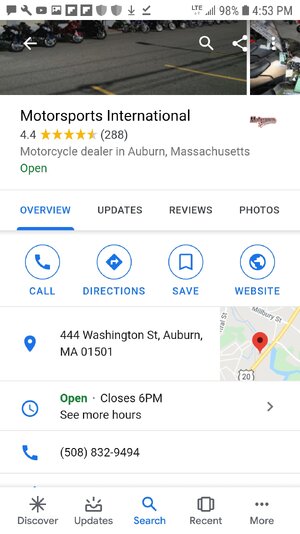

A motorcycle dealer in Auburn ma

Is now a VP racing fuel distributor

Picked up 2 5 gals jugs for under 82$

Its called international motorsports

508 832 9494 .I'm trying to create a demand so they have it in stock

Right now it's on a ordering basis

Is now a VP racing fuel distributor

Picked up 2 5 gals jugs for under 82$

Its called international motorsports

508 832 9494 .I'm trying to create a demand so they have it in stock

Right now it's on a ordering basis