Not true...

Raising the lower pickup point to a move even level with the tie rod pickup point is what aids in fixing the bump steer..

also, I have a set of almost brand new SC&C Double adjustable upper control arms with the extra tall ball joints, AND tall lower ball joints with the progressive rate jounce bumpers that I am looking to sell. FYI SC&C were the first guys to use the taller ball joints to aid in correcting the geometry, everyone else is trying to replicate what SC&C did in the first place..

Here is a write up explaining exactly the causes of Bump Steer...

With that said let's begin with the basics of why we may want to buy new control arms for our cars...

1) Bump Steer- causes, effects, and how to correct it

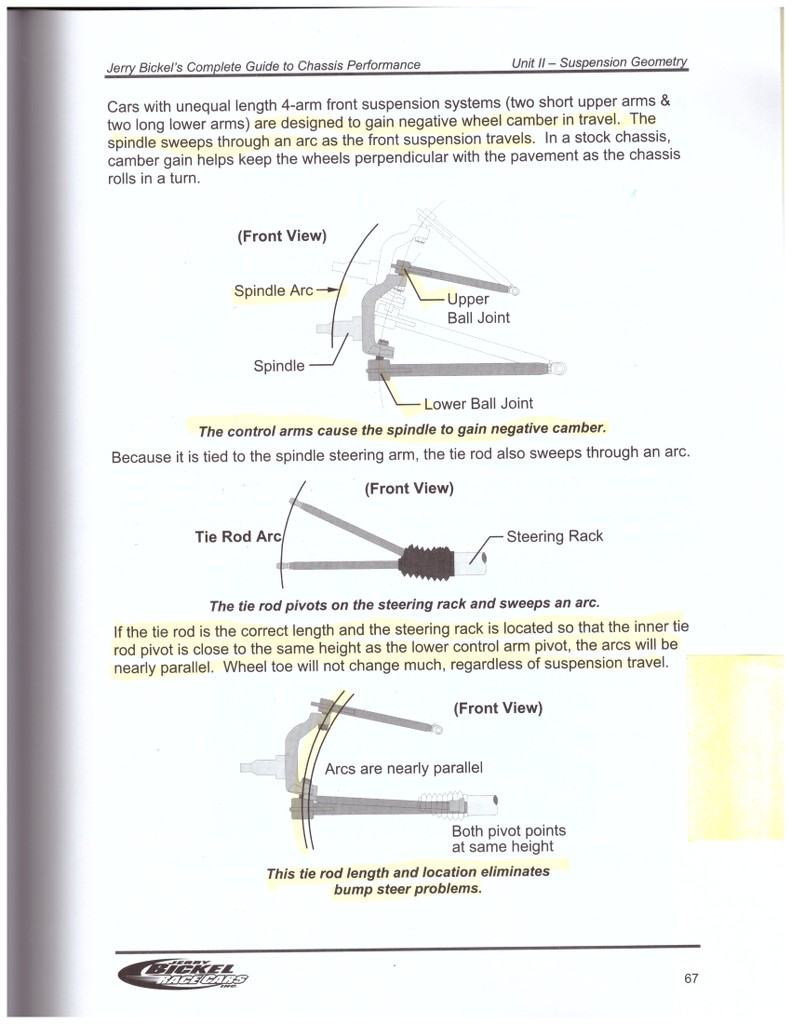

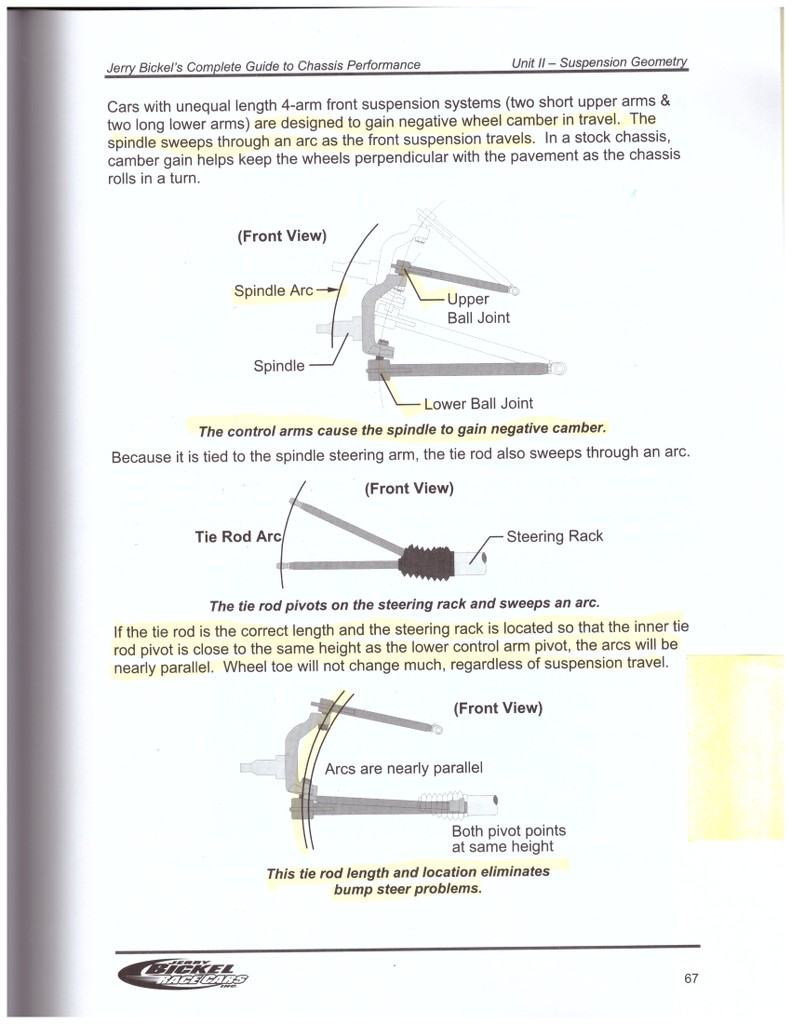

A) Our cars use what is described as a SLA front suspension. This stands for Short Long Arm. This means that our lower control arms are longer than our upper control arms. Our suspension pivots along certain points called Pickup Points. A Pickup Point is the pivot axis of each bushing, center of the ball joint, and tie rod ends. All of these are PP's that the suspension travels along. This means that if you were to look at your suspension from the front, the suspension pivots on these PP's and the location of the PP's create certain arcs, or paths of travel, that the suspension will move along.

B) Bump steer is defined as "..an unwanted change in wheel direction or toe as the suspension travels."

C) As our suspension travels through its' arc the lower control arm pivot point and the tie rod pickup point swing in an arc as well (because they are Pickup Points of the suspension-they are the pivoting axis along which the suspension may travel). If the arcs of the two points-the LCA (lower control arm) PP and the tie rod PP are at different heights, they will have different arcs. This is illustrated in the following drawing from Jerry Bickel's book:

You can see how the tie rod PP and the LCA PP on the spindle have arcs that they swing along during travel. In the picture it shows the tie rod and LCA PP's are almost the same height, which allows them to have an almost parallel arc.

The near-same height of the LCA and tie rod PP's allows for an almost zero-bump steer situation, because their arcs they swing along are almost parallel.

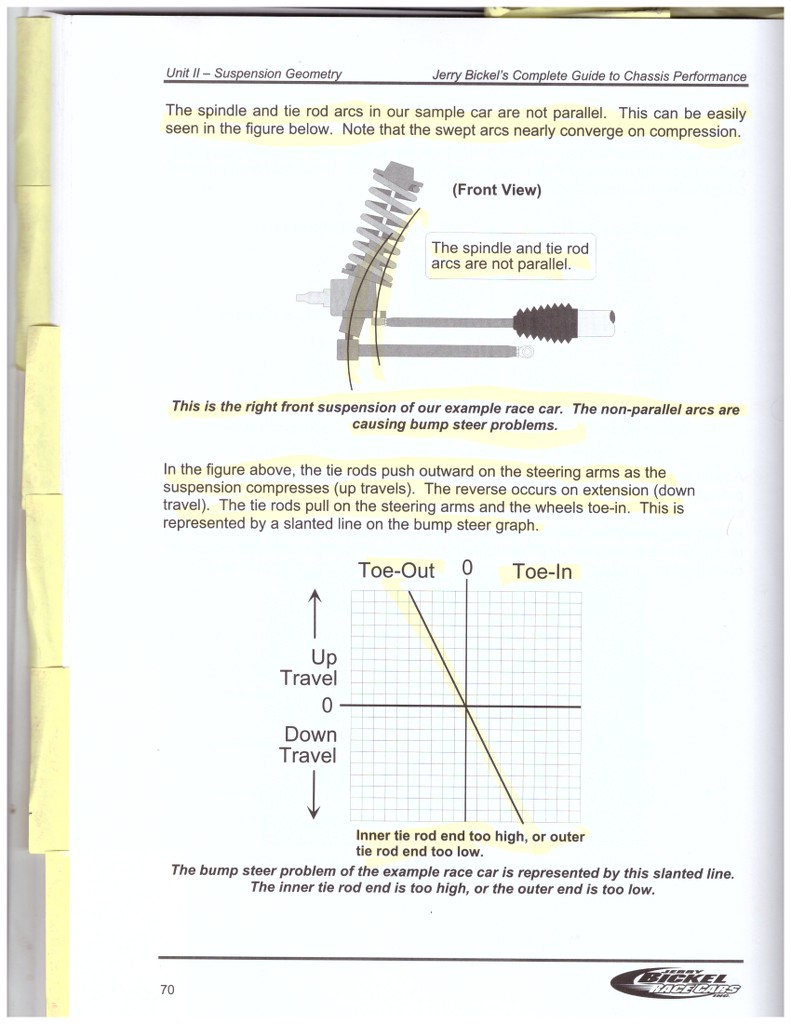

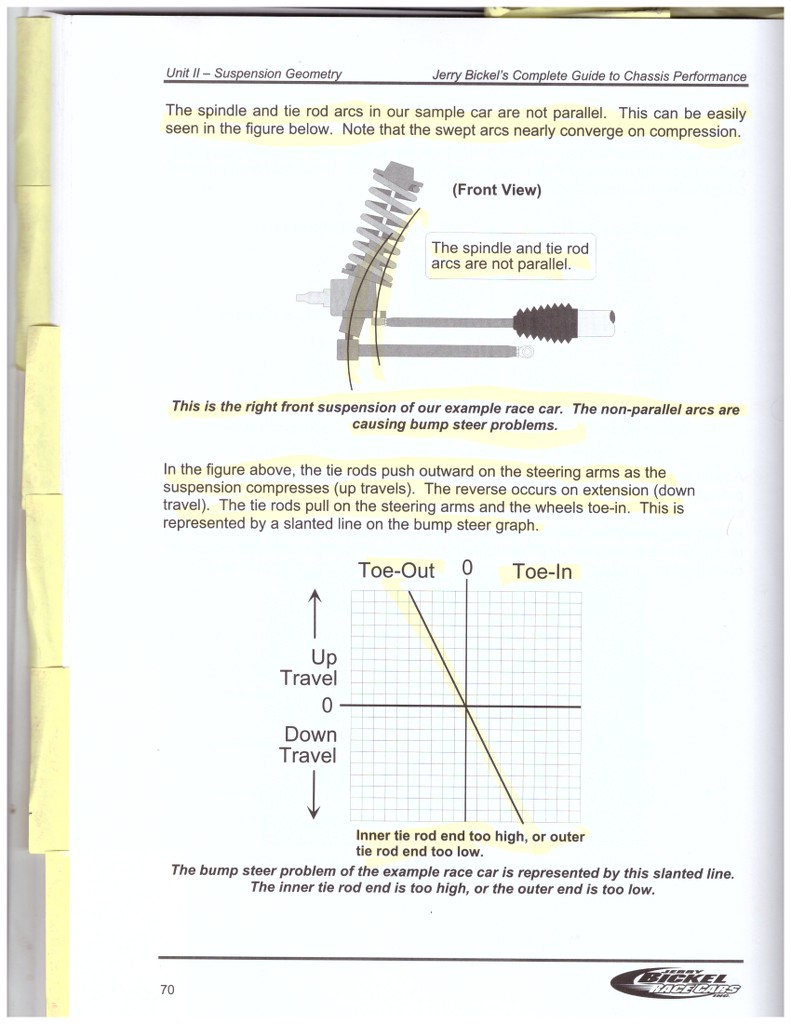

D) Bump Steer in our cars is caused because our tie rod and LCA PP's are not at the same height. To quote Bickel, "Any differences between the spindle and tie rod arcs will cause the tie rod to push or pull on the steering arm. This changes the direction of the wheel, creating bump steer." In a suspension with the LCA and tie rod PP's not equal heights, as the tie rod moves and pulls on the steering arm, it is causing either toe-in or toe-out (this is where the actual direction your wheel is pointing is changed) and thus the change in direction of the car. Here is another drawing from Bickel's book discussing this:

E

) How do we fix this bump steer, now that we know what can cause it?

a) To fix this issue we need to find control arms that help to relocate the LCA PP to a more level position as the tie rod PP sits. A good example of this would the SPC LCAs with taller ball joints that are offered from SC&C. This design does not simply add a taller ball joint and calls it a day, but it physically locates the ball joint to a more favorable position for suspension travel-locating it to a more level height as the tie rod sits when you use the taller ball joints offered with the arms, improving the arc the PP swings along relative to the tie rod. This LCA also addresses caster and camber issues as well, but I won't touch on that right now.. Once we have a lower suspension that has the tie rod PP and the LCA PP to a more level height, we can significantly reduce and almost completely rid ourselves of any bump steer the car may have.

Note: simply adding a taller ball joint to the LCA will not fix this issue. The actual physical position of the ball joint must be changed as well. This is what separates suspension pieces like the SPC lower control arms from the rest of today's offerings- they physically change the location of the ball joint AND use the taller ball joint to locate the LCA pick up point and tie rod pick up point to a more level location. BEWARE of other companies products offering taller ball joints- you must make sure that they are changing the ball joint location as well, which is the real key here.

In my next post, when I get some time, I will go into the coilover vs shock and spring comparison...