Every couple of years, I've developed a leak at the compression fitting on my alky tank. This latest round was after a new tank install and a crack developed at the junction of the nipple and the tank itself. I'm always careful to install in a manner that there is no interference or pressure exerted on the line and fitting at the tank. Did some searching and came up with a good solution which eliminates the ferrule compression fitting and is a more robust connection:

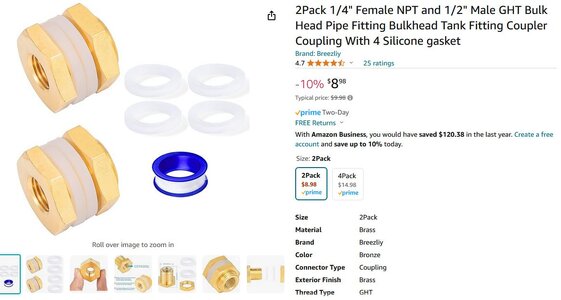

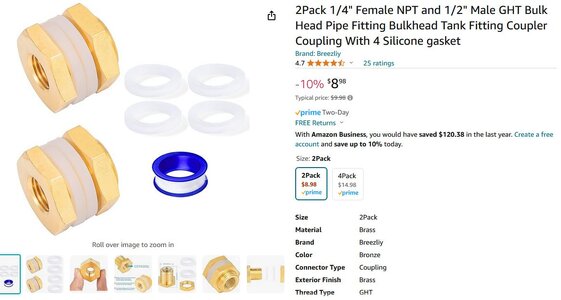

The only items you need for this is your typical wrenches of various sizes to undo/tighten fittings, a sharp razor blade, some white PTFE/teflon paste, and a step bit with a 13/16" hole option, and this bulkhead fitting from Amazon. Pic of the bulkhead fitting for searching later if the URL changes:

Step 1: Drain your alky reservoir. Highly recommend the pressure tester kit for this, or use the test button to drain it into your container of choice.

Step 2: Disconnect the black feed line, low level sensor ground, low level sensor signal wire, and remove the reservoir from vehicle.

Step 3: Remove the low fluid sender by pulling/wiggling straight out. Set it aside along with the grommet.

Step 4: Separate the 90 degree flare to 1/4 NPT adapter from the compression fitting and ferrule pieces and clean existing sealant off of threads. Set aside 90 degree adapter as you will re-use this.

Step 5: Using a sharp razor, cut the nipple, and ferule off and flush with the reservoir.

Step 6: Using a nice and sharp step drill bit at a slow to moderate speed and LIGHT pressure, drill a 13/16" hole using the existing hole where the nipple was. The step bit will allow you to drill a progressively larger hole without potentially shearing too much plastic. ***Be careful on this step because if you're trying to rush and applying too much pressure, you might push right past the 13/16" step and drill a hole that's too large, effectively ruining the whole thing.***

Step 7: Make sure you get all of the shavings and debris out and ream the new hole with a razor if needed.

Step 8: Prepare your bulkhead fitting by applying teflon paste on at least the lower 75% of the threads. The teflon paste does the sealing, NOT the silicone washers. However, the silicone and teflon paste have great methanol resistance.

Step 9: Place one silicone washer on the bulkhead fitting and install it in the tank. Plop it in the fill spout and fish it around until you can pull it through the new hole and snug it up. The hole is just in the right place that it will help keep the nut of the bulkhead fitting captive when tightening down the external nut in the next step.

Step 10: Place the second silicone washer on the protruding fitting and spin the nut down. Snug the nut down with a wrench but do NOT overtighten. Tighten it just to the point before the silicone washers begin to deform and squeeze out. If you go too far, just back it off a little until the washers aren't distorting.

Step 11: Apply teflon paste to the 1/4 NPT side of the 90 degree fitting and reinstall. Again, just snug it down until you get to the correct angle for attaching the feed hose. Don't try to overdo it and go an extra turn, otherwise you'll put too much unnecessary torque on the bulkhead fitting and force it to spin inside the hole. It doesn't take a lot of pressure to get a good seal

Step 12: Reinstall low level sensor and grommet, reinstall reservoir assembly, reconnect feed line and low level power wire and ground.

Step 13: Refill reservoir and check for leaks. Once you're done, you should have something that looks like this and the connections should maintain the same geometry as before, more or less:

The only items you need for this is your typical wrenches of various sizes to undo/tighten fittings, a sharp razor blade, some white PTFE/teflon paste, and a step bit with a 13/16" hole option, and this bulkhead fitting from Amazon. Pic of the bulkhead fitting for searching later if the URL changes:

Step 1: Drain your alky reservoir. Highly recommend the pressure tester kit for this, or use the test button to drain it into your container of choice.

Step 2: Disconnect the black feed line, low level sensor ground, low level sensor signal wire, and remove the reservoir from vehicle.

Step 3: Remove the low fluid sender by pulling/wiggling straight out. Set it aside along with the grommet.

Step 4: Separate the 90 degree flare to 1/4 NPT adapter from the compression fitting and ferrule pieces and clean existing sealant off of threads. Set aside 90 degree adapter as you will re-use this.

Step 5: Using a sharp razor, cut the nipple, and ferule off and flush with the reservoir.

Step 6: Using a nice and sharp step drill bit at a slow to moderate speed and LIGHT pressure, drill a 13/16" hole using the existing hole where the nipple was. The step bit will allow you to drill a progressively larger hole without potentially shearing too much plastic. ***Be careful on this step because if you're trying to rush and applying too much pressure, you might push right past the 13/16" step and drill a hole that's too large, effectively ruining the whole thing.***

Step 7: Make sure you get all of the shavings and debris out and ream the new hole with a razor if needed.

Step 8: Prepare your bulkhead fitting by applying teflon paste on at least the lower 75% of the threads. The teflon paste does the sealing, NOT the silicone washers. However, the silicone and teflon paste have great methanol resistance.

Step 9: Place one silicone washer on the bulkhead fitting and install it in the tank. Plop it in the fill spout and fish it around until you can pull it through the new hole and snug it up. The hole is just in the right place that it will help keep the nut of the bulkhead fitting captive when tightening down the external nut in the next step.

Step 10: Place the second silicone washer on the protruding fitting and spin the nut down. Snug the nut down with a wrench but do NOT overtighten. Tighten it just to the point before the silicone washers begin to deform and squeeze out. If you go too far, just back it off a little until the washers aren't distorting.

Step 11: Apply teflon paste to the 1/4 NPT side of the 90 degree fitting and reinstall. Again, just snug it down until you get to the correct angle for attaching the feed hose. Don't try to overdo it and go an extra turn, otherwise you'll put too much unnecessary torque on the bulkhead fitting and force it to spin inside the hole. It doesn't take a lot of pressure to get a good seal

Step 12: Reinstall low level sensor and grommet, reinstall reservoir assembly, reconnect feed line and low level power wire and ground.

Step 13: Refill reservoir and check for leaks. Once you're done, you should have something that looks like this and the connections should maintain the same geometry as before, more or less: