Chris Hogeland

TWISTED 6 RACING

- Joined

- May 28, 2006

Sent from my iPhone using Tapatalk

Last edited:

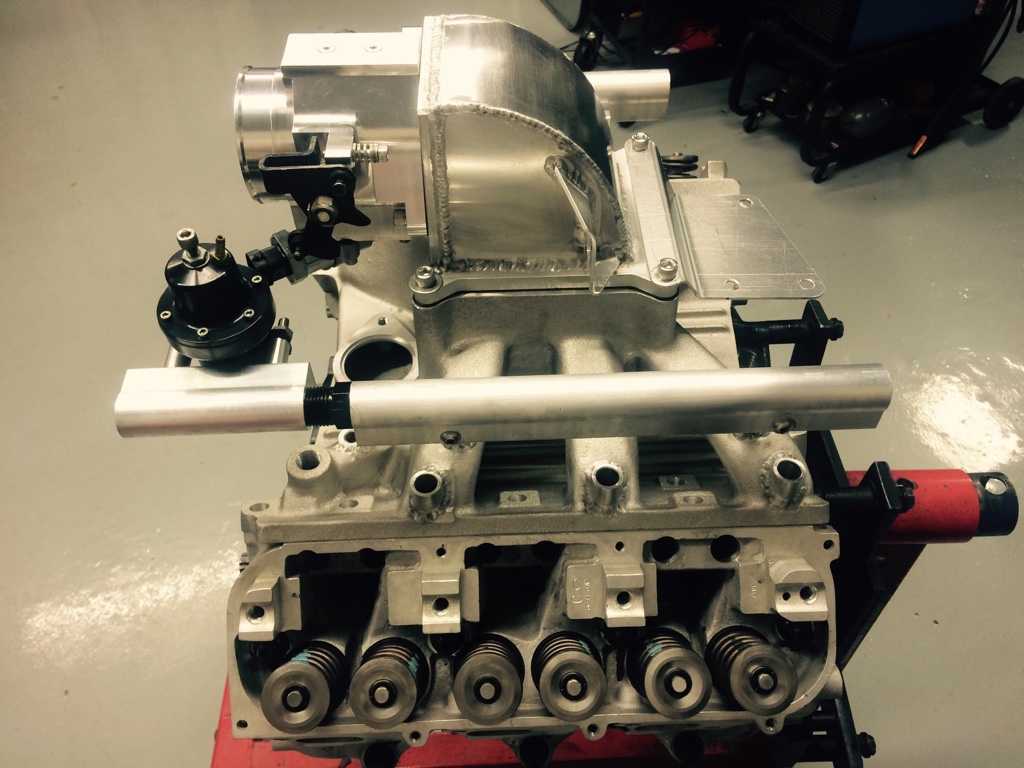

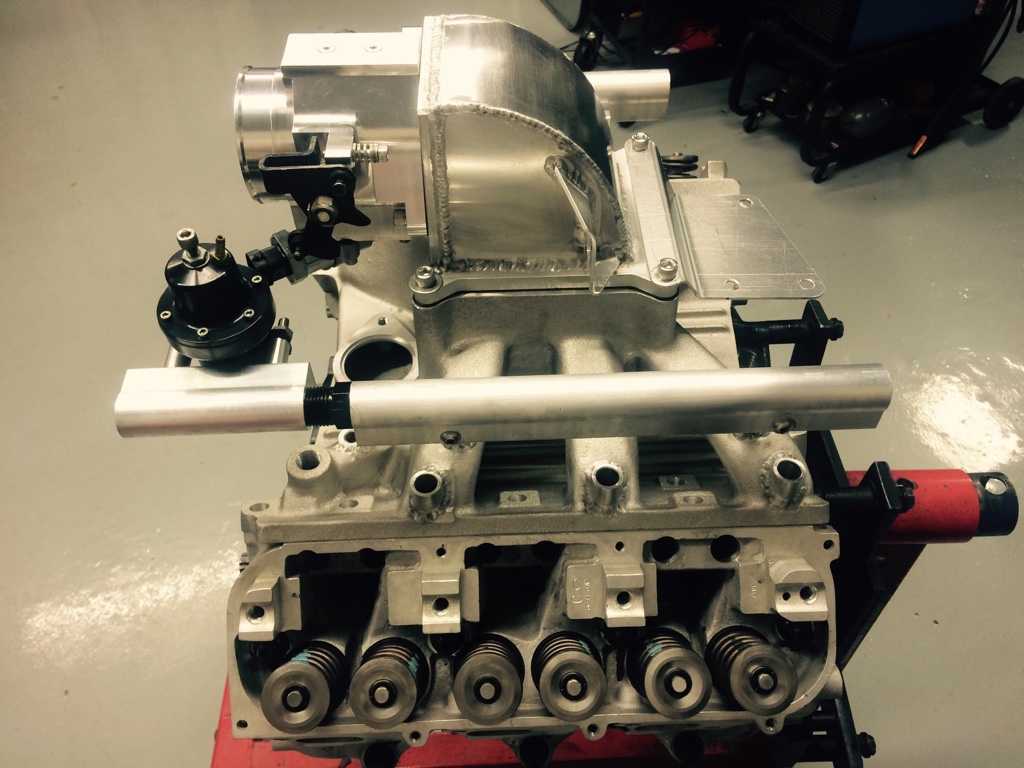

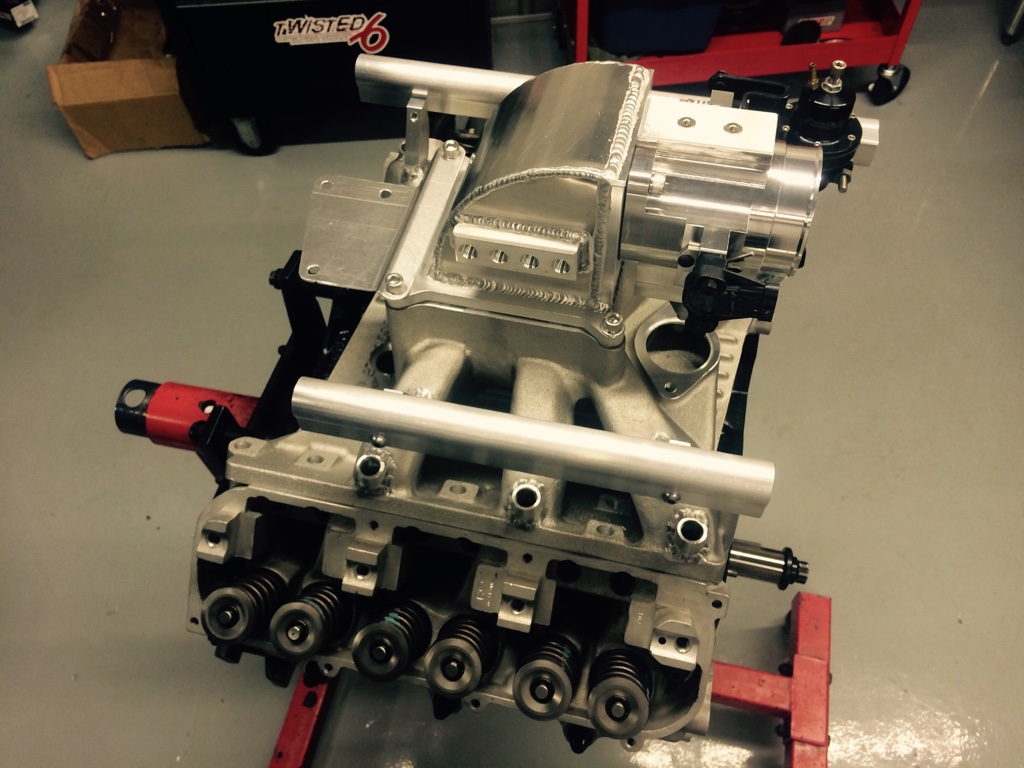

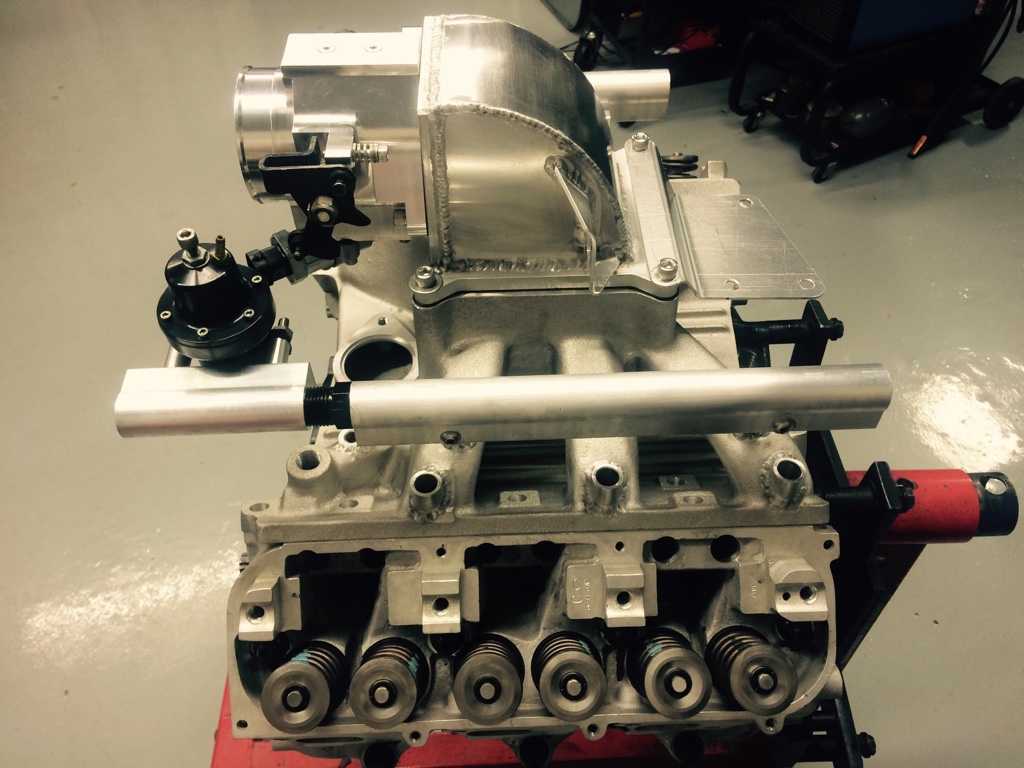

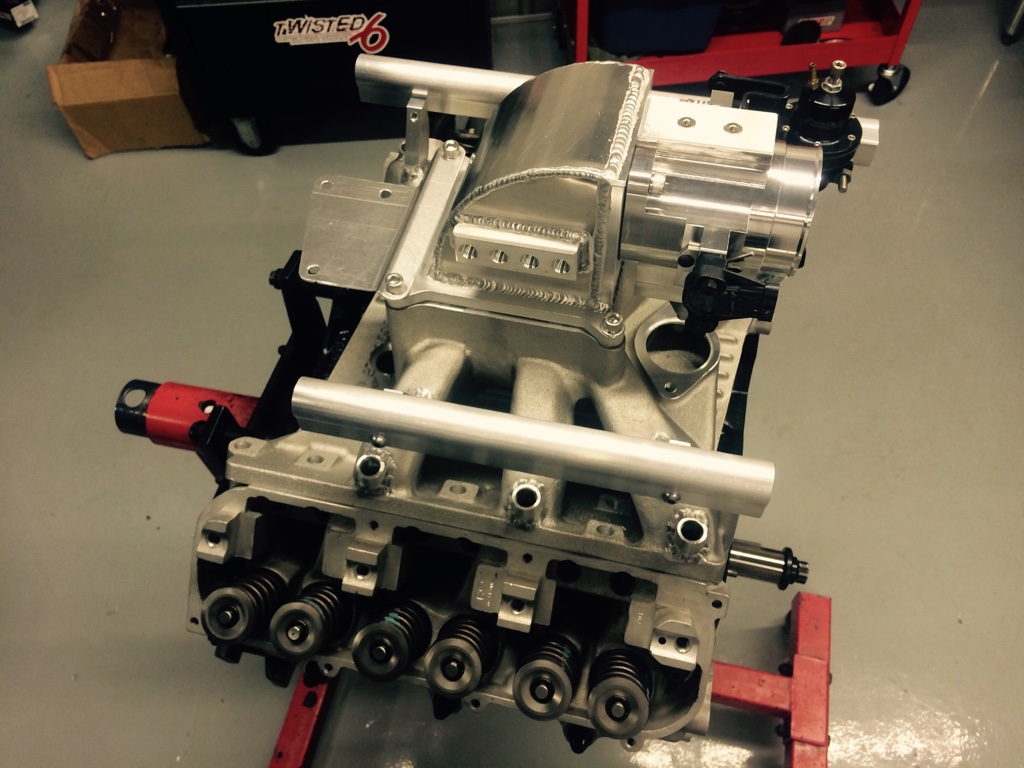

I cant wait to see it with all it's stuff bolted on and mocked up on the stand. I like the way you did the regulator on the rail. I have mine on the rail as well. I used an o-ring to pipe fitting. Problem is, when you tighten it up if it doesn't stop where you want it, you have to back it out and run a tap a little deeper. It's sort of trial and error. Your set-up seems simpler.

Sent from my iPhone using Tapatalk

http://www.oldbuickparts.com/catalo...iator-support-seal-1981-87-buick-p-25968.htmlIs anyone still making the radiator baffle kits anymore? I still have an old anodized ATR set up in use, very effective for front mount and radiator air flow.

Yes, I agree. I looked more closely and now I realize it's a stock configured regulator. I thought it was an Aeromotive. When I said I had mine on the rail, I meant I threaded it on with an adapter instead of mounting it to the fender or fire wall. I'm using a big Aeromotive pro-regulator and you should look into something like this as well. Especially if you may want to play around with e-85 in the future.For power levels at this level, I would NOT recommend a stock style fuel pressure regulator. At 750 HP I have to ream the internal stand pipe up as far as I can and still leave enough material for the diaphragm puck to seal against.

I would suggest a remote mount aftermarket regulator. Look closely at the ID of the outlet of that regulator. I just had to also upgrade to a -6 AN return line even after removing all the Saginaw fittings on the entire system. At idle/cruise you are going to NEED a large by-pass circuit.

For power levels at this level, I would NOT recommend a stock style fuel pressure regulator. At 750 HP I have to ream the internal stand pipe up as far as I can and still leave enough material for the diaphragm puck to seal against.

I would suggest a remote mount aftermarket regulator. Look closely at the ID of the outlet of that regulator. I just had to also upgrade to a -6 AN return line even after removing all the Saginaw fittings on the entire system. At idle/cruise you are going to NEED a large by-pass circuit.

Cal Hartline is your new best friend. Cal can tune a hummingbirds wings while in flight. Beehtoven had Cal tune his stuff........... I jest, but Cal would be my choice at your level. (and he couldn't be farther away from me and still,be inside the US borders)

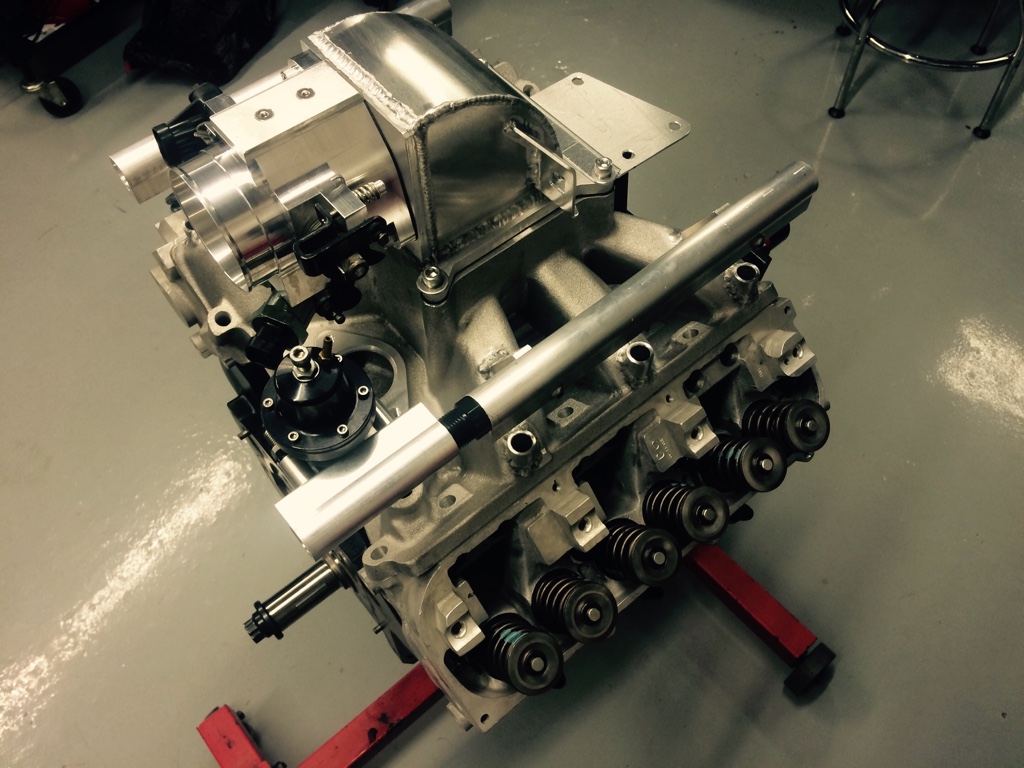

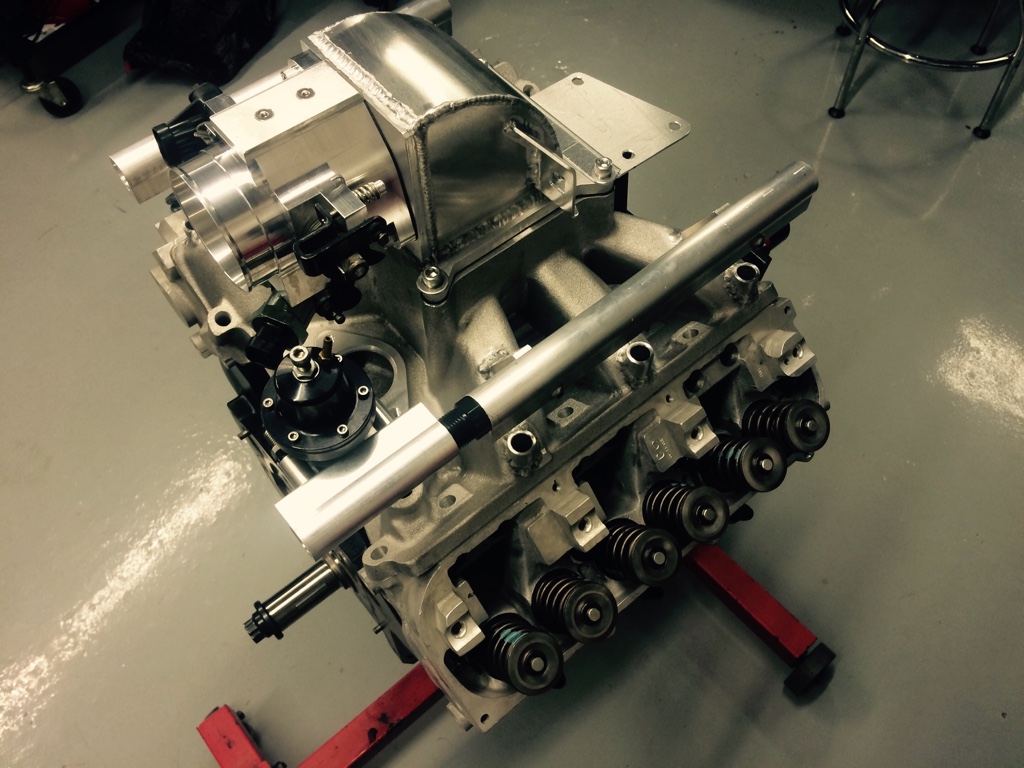

My first set is Moroso, they used to make a set of alternator brackets that gave you the option of either side to mount the engine. High on the driver side and low on the passenger side. Moroso used to carry a lot of the oil pans, alt. brackets, belt drives, and pulley's for the stage 2 stuff. I will go thru boxes and boxes and look. After buying so many of these motors you tend to keep the extra small parts that come on them. I bet Mike Booher would have some. You could also go custom, it's just aluminum and proper spacing. I doubt if there are any stage 2 guys out there that doesn't have several v- belt mandrels, gilmer drives and brackets that they didnt need just laying around. Hopefully you will get a good response. I dont have the champion set up on either of my twin turbo motors. I will try to get you some pics also.

Do you plan to run a skinny front tire? I missed my power steering for about 3 minutes. I use an S-10 manual steering box. Just the slightest bit of roll with a skinny front tire and it feels no different then my stock sh't box 4 door 98' Honda Civic. You may want to consider it as an option.I'd like to see how you did the accessory mounts on your TT setups, I know my alternator is going to get in the way and there is a 0 % chance I'm giving up P/S.

Mike