Already has a cooler charge. Upgraded fuel rails due to other upgrade are in place but stock lines are being used. From the one pass we did get in it runs pretty much like it did down the track no issues with lean, had we not started losing oil pressure due to an oil swap (next time staying with what I know works in my set up). Hoping to be back out soon.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What do you need to run e85

- Thread starter gteatr6

- Start date

Converted over tonight. I must have had a bad injector the whole time I've owned this car, or E85 is just that much better. The car idles great, before it sounded like it had a cam. It would sometimes die when cold and bogged down under wot. Now the throttle is instant, and the best part is I payed 2 dollars a gallon for the E85

Anyone have a powerlogger for sale???

Anyone have a powerlogger for sale???

BEATAV8

The Engine Whisperer

- Joined

- Feb 14, 2002

Now the throttle is instant, and the best part is I payed 2 dollars a gallon for the E85Anyone have a powerlogger for sale???

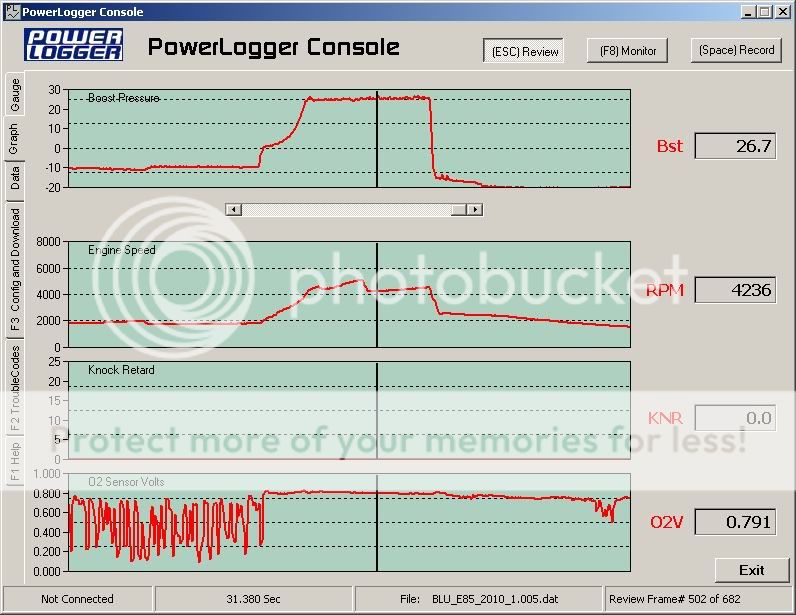

Whatever you do, don't beat on it until you a power logger on it. It is an absolute must... and when you do get a PL installed, ease into the tune a little bit at a time, starting with low boost and short runs. Got to make sure you have enough fuel!

BEATAV8

The Engine Whisperer

- Joined

- Feb 14, 2002

A lot of people do report that the engine will sound smoother on E85

I concur with that. Noticeably smoother compared to gasoline. Quite nice actually.

Originally Posted by TurboBob

cold start in the driveway.

Once warmed up, its fine.

Bob

Bob, Don't you make your own chips?

yup, I think some of the cold running issues are related to low compression and cold plugs. I really haven't fiddled with it much.

I want to try some hotter plugs, but for now, its well worth the tradeoff.

The car flat out flies. :biggrin:

Bob

I want to try some hotter plugs, but for now, its well worth the tradeoff.

The car flat out flies. :biggrin:

Bob

I have an 2008 gmc serria flex fuel. I ran e85 all winter. I can say when it was really cold (10*F) it used lots of fuel but it ran perfect. If you decude to sell any of those chips......

Yes- from cold start the entire bit to closed loop calls for a lot of fuel on the FFV's. 1 tip on an FFV- keep them moving if possible until they have reached full temp because if you only go a mile or so then shut off to go in a c-store for a coffee, you seem to have to go back thru cold enrichment all over again.

I suspect that the very rich cold enrichment is why FFV's really do start and run as good on E85 on cold mornings as they would on gas. But if you lived in a city and only did short trips then you would not like the consumption as much as those of us with longer trips.

I have an 2008 gmc serria flex fuel. I ran e85 all winter. I can say when it was really cold (10*F) it used lots of fuel but it ran perfect. If you decude to sell any of those chips......

All my chips are sold by Full Throttle. You just have to order them set up for E85.

All my chips are sold by Full Throttle. You just have to order them set up for E85.

Thanks Bob. I wanted to order a e85 chip this spring, however Mike talked me out of it. I like the 'safety' of running 105 octane. After hearing everyones accounts of how great their car runs on the stuff makes me want to send my chip back. What fuel pump are you using?

I guess I have offically highjacked this thread. Sorry to the OP.

So to run e85 below 21 psi You need a

Hot wired pump

walbro pump

80lb injectors

chip for injectors

I currently have a TE51 turbo with 42 lb injectors. I have the hot wired pump and walbro pump. The bosch 044 pump looks intresting 200lph at 72.5 psi. Now if I could only convert liters per hour to lb per hour. Thanks for the help Bob.

Edit I come up with 330 lb per hr assuming gasoline weighs 6.25 lbs per gallon. Far shy of 480lbs per hour (80 lb injectors X 6)

I'm running a single Walbro, but its not enough for anything over about 21 psi. I need to work out something to improve my fuel supply.

Bob

So to run e85 below 21 psi You need a

Hot wired pump

walbro pump

80lb injectors

chip for injectors

I currently have a TE51 turbo with 42 lb injectors. I have the hot wired pump and walbro pump. The bosch 044 pump looks intresting 200lph at 72.5 psi. Now if I could only convert liters per hour to lb per hour. Thanks for the help Bob.

Edit I come up with 330 lb per hr assuming gasoline weighs 6.25 lbs per gallon. Far shy of 480lbs per hour (80 lb injectors X 6)

BEATAV8

The Engine Whisperer

- Joined

- Feb 14, 2002

I guess I have offically highjacked this thread. Sorry to the OP.

So to run e85 below 21 psi You need a

Hot wired pump

walbro pump

80lb injectors

chip for injectors

I currently have a TE51 turbo with 42 lb injectors. I have the hot wired pump and walbro pump. The bosch 044 pump looks intresting 200lph at 72.5 psi. Now if I could only convert liters per hour to lb per hour. Thanks for the help Bob.

Edit I come up with 330 lb per hr assuming gasoline weighs 6.25 lbs per gallon. Far shy of 480lbs per hour (80 lb injectors X 6)

You'll want to look at how much of those 42's you are using now and then add about 30%. That'll give you an idea of how much you'll be pushing the 80's. This math seems to work out OK if you were using 100 or 105 octane to start out with, and running roughly the same boost you will be running with E85....

In my case, when I was running 100 octane gasoline I was pushing my 42's to 100%, so that's 42x6 = 252lb/hr. For E85 "they say" to add 30%. So 30% of 252, that's about another 75lb/hr, totaling about 325lb/hr. So when i installed my 80's I knew I needed to get 325lb's out of them, so 325/480 = 0.68 or 68% injector duty. This helps when you want to take a swag at where you think you're gonna end up.

Anyways, after adding just a little more boost and fattening it up a smidge for comfort, I'm right at 75% injector duty, which is 360lb/hr on the 80's. Once again, "they say" in practice that 60lb injectors is about all that a single 340 pump running 70psi can support.... maybe just a little more if the voltage supply is really decent. And... 6X60=360lb. Guess that's it for me. No mo pump....

there's so much fuel pump flow data out there for the 340.... who knows what it can really do. 40GPH? 50GPH? 60GPH?

Seems to me that it can indeed fully support 60's (360lb/hr).

http://www.gnttype.org/techarea/images/XP.gif

Flow Chart Comparison

:biggrin::biggrin:

I don't think you highjacked this thread. I started it and so far all I've seen is some good info and some ideas I never thought about.:biggrin: I never thought it would be 3 pages either!

I guess I have offically highjacked this thread. Sorry to the OP.

So to run e85 below 21 psi You need a

Hot wired pump

walbro pump

80lb injectors

chip for injectors

I currently have a TE51 turbo with 42 lb injectors. I have the hot wired pump and walbro pump. The bosch 044 pump looks intresting 200lph at 72.5 psi. Now if I could only convert liters per hour to lb per hour. Thanks for the help Bob.

Edit I come up with 330 lb per hr assuming gasoline weighs 6.25 lbs per gallon. Far shy of 480lbs per hour (80 lb injectors X 6)

I don't think you highjacked this thread. I started it and so far all I've seen is some good info and some ideas I never thought about.:biggrin: I never thought it would be 3 pages either!

gteatr6, Thanks for your patience.

beatav8, You must be running a single walbro as well. However, It appears my number for lbs per gallon of gasoline must be wrong. Using the 6.25 gal per lb and using the 42.6 gal per hour @70psi from the graph, you should have run out of pump. I come up with 266 lbs per hr. I guess this is where the powerlogger comes into play. Thanks for your help.

beatav8, You must be running a single walbro as well. However, It appears my number for lbs per gallon of gasoline must be wrong. Using the 6.25 gal per lb and using the 42.6 gal per hour @70psi from the graph, you should have run out of pump. I come up with 266 lbs per hr. I guess this is where the powerlogger comes into play. Thanks for your help.

BEATAV8

The Engine Whisperer

- Joined

- Feb 14, 2002

gteatr6, Thanks for your patience.

beatav8, You must be running a single walbro as well. However, It appears my number for lbs per gallon of gasoline must be wrong. Using the 6.25 gal per lb and using the 42.6 gal per hour @70psi from the graph, you should have run out of pump. I come up with 266 lbs per hr. I guess this is where the powerlogger comes into play. Thanks for your help.

I think your number of 6.25 is OK, but there's lots of different fuel pump flow charts for the 340 out there on the net. All are different. Some show ~60gph at 70psi, others show ~40 GPH 70psi. Who knows what it can really do.... who knows which graph is correct?

Something to keep in mind though is that the fuel pump flow availability increases substantially as the restriction is reduced. When I say restriction I'm referring to the injectors.... As big injectors open up they become a low restriction, sure the fuel pressure falls off, but it's actually not such a bad thing since the flow availability from the pump really goes up with low pressure. After all, the real goal is to get fuel from the fuel tank into the engine.

At WOT a garden hose would work just fine ;-)

BEATAV8

The Engine Whisperer

- Joined

- Feb 14, 2002

Doesn't the fuel pressure need to stay up pound for pound with boost because of the intake pressure?

Ideally it should, if you are looking to deliver fuel at a rate similar to what the injectors are rated for. But for the case of very large injectors and a single fuel pump, you can easily run into the situation I described above where the restriction is very low and the flow is very high. As long as the fuel pressure is more than the boost pressure, then fuel will flow from the rail and into the intake manifold.

The reason for the loss in fuel pressure is the injectors themselves. If they're very large and running wide open, then they will deliver everything the pump has to offer all the way to the point where the fuel rail pressure is just slightly above the boost pressure. That's where the flow will level off and no more is possible. At this point you will not be getting what the injectors are rated for, but you will getting everything the pump can push. For example, if we assume 10psi drop across the vehicle fuel lines from back of the car to the front at high flow, and 25psi boost and just about 25 psi of fuel pressure in the rail, that would mean the pump would see about 35psi at it's outlet. A Walbro flows quite a bit more at 35psi compared to what it can do at 70psi. (extreme example here...BTW)

Think of the fuel system as a garden hose with a nozzle. When the nozzle is closed, the pressure in the garden hose is at it's maximum and the hose is stiff. As you open the nozzle, the flow increases. As you open the nozzle all the way, the flow goes to maximum but now the hose has lost pressure inside and it's soft. (don't get GAY here Vern! all this soft and stiff talk will get you going I'm sure....)

Similar threads

- Replies

- 19

- Views

- 2K

- Replies

- 0

- Views

- 246