Hector Hernandez

Al throttle no bottle :)

- Joined

- Feb 1, 2013

- Messages

- 63

Can it be the heads I bought are milled to much

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!

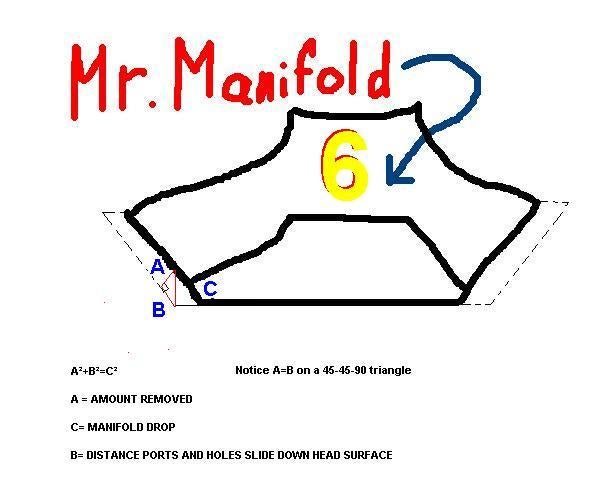

I did the math a while back. If you need to drop the holes .010", for example, you need to mill the exact amount off the intake flange.

Sometimes you can drop the manifold down enough just by using a GM style thin metal gasket instead of a thicker Fel-Pro gasket.