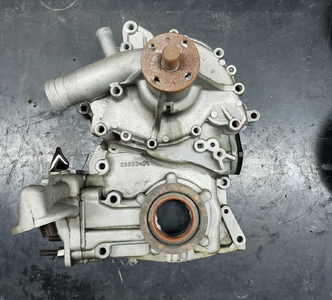

I’m trying to wrap my brain around my failure here. I have a new engine that was ran for less than 5 miles then cut off for the night. I tried to restart it and the xfi showed no oil pressure or ignition signal. I pulled the cam sensor and the gear was destroyed. I had the oil pump and cover blueprinted by a reputable GN shop. When I removed the timing cover, the oil pump shaft would not turn (even with a screw driver) and the tang that goes in the cam sensor was blue. I barely cracked the bolts loose on the oil pump and it spun freely by hand. There was no metal in the pump, no metal in the oil pump pickup screen and nothing on the #2 main bearings. Is there a smoking gun as to why this could have happened? Cam thrust was set correctly. After comparing to an OE timing cover, I realized that mine was apparently a Chinese cover. Could a misaligned cover cause a tightly set up oil pump to bind and lock up once I tightened the cam sensor down? The only other thing I’m thinking could have been cam interference but I don’t see anything glaring yet without tearing completely down. This was a ductile roller cam. Does this sound like a timing cover issue?

Attachments

-

4B6A361F-73E4-4E66-8DC8-C2F4157A63D7.jpeg2.4 MB · Views: 159

4B6A361F-73E4-4E66-8DC8-C2F4157A63D7.jpeg2.4 MB · Views: 159 -

D31FD084-BEE9-4212-9F29-AF875FB083C5.jpeg1.9 MB · Views: 140

D31FD084-BEE9-4212-9F29-AF875FB083C5.jpeg1.9 MB · Views: 140 -

A5E17A19-1870-4451-A685-02F79C55DD8F.jpeg1.3 MB · Views: 134

A5E17A19-1870-4451-A685-02F79C55DD8F.jpeg1.3 MB · Views: 134 -

D0FF5B18-C6A8-4F53-AB04-3ED57B701755.jpeg1.8 MB · Views: 138

D0FF5B18-C6A8-4F53-AB04-3ED57B701755.jpeg1.8 MB · Views: 138 -

61C89438-4113-46EF-BBE4-29683504C72E.jpeg1.4 MB · Views: 151

61C89438-4113-46EF-BBE4-29683504C72E.jpeg1.4 MB · Views: 151