WarWagon

Caustic Cacophony

- Joined

- Mar 10, 2007

- Messages

- 2,362

March 2020 update:

Just got my last few pieces to install and finish.

I got the stock headers on and my fabricated down pipe is fitting although close to the crossover flange. I'm setting up my new airfilter system and installing a pre turbo inline oil filter.

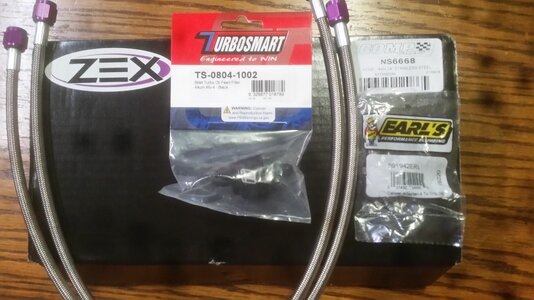

This is a Turbosmart -4AN filter and ZEX -4AN lines with two Earls adapters to -4AN.

I'm about to get this all sorted out and hit the road.

Just got my last few pieces to install and finish.

I got the stock headers on and my fabricated down pipe is fitting although close to the crossover flange. I'm setting up my new airfilter system and installing a pre turbo inline oil filter.

This is a Turbosmart -4AN filter and ZEX -4AN lines with two Earls adapters to -4AN.

I'm about to get this all sorted out and hit the road.