Having trouble just all of a sudden. A quick look I don't see an exhaust leak, and I swiped out boost solenoid. Im using a TurboSmart Street. no improvement

Ill be removing all the exhaust to get a good look at everything and Im thinking of installing some copper exhaust gasket I have. What's your thoughts?

I have not ran gaskets for a very long time and all the bolts are tight.

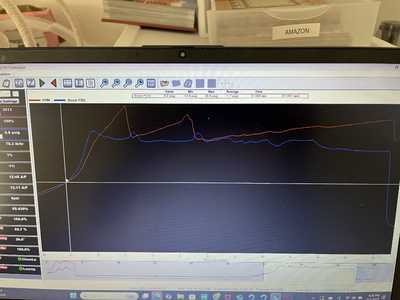

This is the 1st pass and 2ed 15 minutes later

Ill be removing all the exhaust to get a good look at everything and Im thinking of installing some copper exhaust gasket I have. What's your thoughts?

I have not ran gaskets for a very long time and all the bolts are tight.

This is the 1st pass and 2ed 15 minutes later