Theory of operation for most external wastegates:

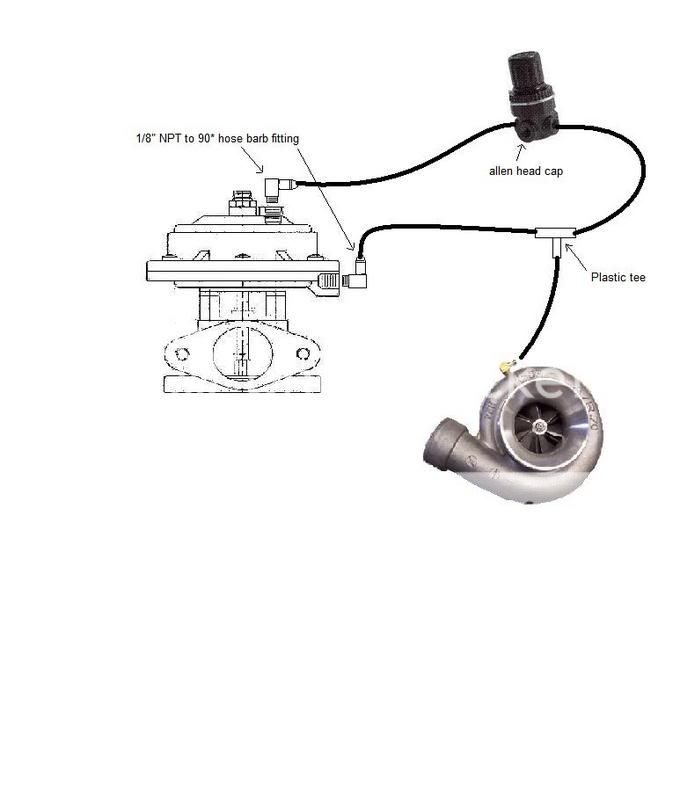

Boost reference signal from the turbo/intake manifold, gets divided equally at the tee. With the bleeder valve closed, all signal pressure goes to the bottom of the wastegate and boost is regulated by whatever spring you have installed in the wastegate and the tension set by the adjustment screw. (if it has one) Once the exhaust pressure flowing through the wastegate overcomes the spring rate, the valve opens and exhaust velocity is decreased and stabilized. Thereby controlling the speed that the turbine wheel and compressor wheel spin at.

Once you open the bleeder valve, it allows the pressure signal to reach the top of the wastegate. This effectively increases the spring rate of the wastegate. The more boost reference signal you add to the top of the wastegate, the more exhaust pressure is required to open the wastegate valve. The more exhaust pressure that hits the turbine wheel, the more boost pressure is created by the compressor wheel. (IE: Turbos rotating assembly spins faster) Typically, with the air compressor style bleeder valves, you can double whatever the spring rating is. (Ex: If your wastegate spring is 15psi, you should be able to reach 30-32psi with the bleeder valve fully opened) Note: Actual final boost level can vary, due to different motor and parts combinations and ambient conditions.

With the Sears air compressor bleeder valve I have pictured, there is a direction of flow arrow cast into the body. You need to make sure that this arrow is pointing towards the wastegate only. Also, the side port in the bleeder valve is for a small gauge that comes with the valve from Sears. They also include a 1/8" NPT allen head pipe plug if you choose not to use the gauge. If you install the bleeder valve inside the center console or under the dash, that gauge is useless.

Hope some of this helps a little.

Patrick