Just so you know, even though ATR is out of business, if you ever have to replace that wastegate, you can run a Tial 38mm or even a Turbonetics Deltagate wastegate in it's place if it ever freezes up or stops working.

There is a vent plug in the top of your wastegate, remove it, go to the hardware store and get a 90* hose barb fitting that is the same threads as your fitting you took out and same size hose barb as your hoses. My guess is, it's 1/8" NPT but check it to make sure. Take the factory grey Y out of the vacuum lines. Take your boost controller with you to the hardware store as well. On the side of the valve that has nothing going to it, get a hose barb fitting that will thread into the previously open to atmosphere port. That valve you have will work, but I have always prefered the standard air compressor style regulator valves myself. They move more air and are more reliable over years of use. Available at Sears, Precision Turbo, Turbonetics (Jack Cotton) and other stores that sell air compressor parts and accessories.

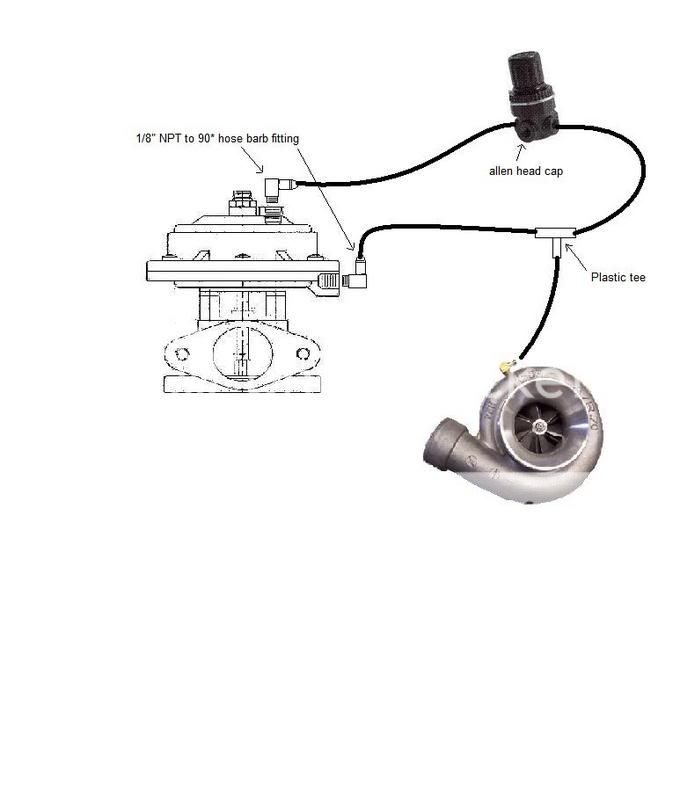

Re-install your new brass 90* hose barb fitting into the top of your wastegate. Get a new Tee (plastic or brass) and hook your vacuum lines up like this drawing. Making sure that both lines that are going to the wastegate are split evenly. Meaning the orientation of the tee, the bottom of the tee goes to the hose barb fitting on your turbo. Each top end of the tee, goes to the wastegate fittings. Also, your valve and the air compressor valves have a direction of flow arrow. The outlet should be plumbed towards the top of the wastegate. (Very important)

If you want, you can keep the boost control valve under hood, or you can route it inside the car. Redoing your vacuum lines and boost control valve like this drawing, is what is called a Closed Loop system.

Your current configuration is what is called an Open Loop system. Boost can vary wildly with conditions using the Open Loop method.

The Closed Loop configuration is what I recommend to anyone who is running an external wastegate. I have ran all of my external setups like this for years, and have had pin point boost control on the fly.

With the Closed Loop setup, when setting your base boost level, you have the boost valve closed completely, so as not to let any boost hit the top of the wastegate. Now, starting with the set screw turned all the way out so that there is no preload on the wastegates spring, (tightening the jamb nut after each adjustment) your boost should be at or near the wastegate springs rate. EX: If your wastegate has a 17# spring, your boost should be very close to 17psi. This will can also be affected by what turbine wheel you have and the efficiency of your engine. IE: how much exhaust it moves due to head work, intake, big cam, etc, etc.

Once you have your base boost set where you want it, again, tightening down the jamb nut after each adjustment you make to the set screw before testing, (we don't want that set screw and jamb nut to go flying off the car during testing. Been there, done that) you either slowly start opening the boost control valve under WOT, or, turn the valve in 1/4 turn increments to set your boost. NOTE: Not all bleeder valves are as sensitive to adjustment as others. A 1/4 turn might be 1psi on one bleeder valve, where it might be 3psi on another. So use common sense when turning up the boost. If you know your car only has 93 pump gas, don't go crazy with the bleeder valve. (Boost control valve)

If you have pure C-16 in the tank, never fear!!! You'll blow the heads off the car first.

Just kidding, but you get the picture.

I have always run my bleeder valve inside the center console and just used rubber vacuum hose. Making sure to firmly zip tie all vacuum hose connections at each hose barb. There's nothing worse than blowing a hose off on your boost control setup while under WOT. Again, been there, done that. One last thing, it is very important when running an external wastegate and a downpipe like you have, that you port the turbine housing wastegate hole, to the same ID as the piping feeding your wastegate. This is a very critical step for pin point boost control. But just remember, when and if you ever go to sell the turbo and or turbine housing, it's very important to let the potential buyer know that the wastegate hole has been ported for use with an external wastegate. As that hole dia will be too large to be used with an internal wastegate. I know way too many people who have been burned by this and have been stuck waiting for turbine housings to be produced.

Hope some of this helps a little.

Patrick