RED LS1

SENIOR MEMBER

- Joined

- Dec 31, 2001

- Messages

- 837

It's cool. I really appreciate that. I think i'm two washers away from it being where I want it for now. I'm ready to get this thing started up and running again.

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!

Pushes it forward into the sway bar? That's what mine is doing. And when you say level is that what you're referring to?

You can weld on a small piece to the bar and drill another hole. I did that.It sits higher on the driver side, you can’t adjust because then it won’t align with the turbo. Only options would to make another holding bar or add another mounting stud to the intercooler.

Sent from my iPhone using Tapatalk

You can weld on a small piece to the bar and drill another hole. I did that.

I see. Great, now i'm gonna go home and put a level on it haha.

Can you loosen the turbo compressor and clock it to help? I had to do that years ago with a Mease SLIC.

Hello there. That's a good idea. How's everything in Missippi? It's someone you've spoken to before. I'm in Boston. Hope you are well. I also added a piece of material [Black trunk pad] I had lying around, to top side of "air box" at the bottom, where it comes in contact with bottom side of radiator support, just in case, knock! I am waiting for "oil bypass" o/ring, or should I say "Quad rings" from R.C.G. They are the perfect diameter, and they are of the quad ring design. [Superior sealing.] Take Care...Use a plenum spacer if you need room for a 4” air inlet pipe.

View attachment 394488

Hello there. That's a good idea. How's everything in Missippi? It's someone you've spoken to before. I'm in Boston. Hope you are well. I also added a piece of material [Black trunk pad] I had lying around, to top side of "air box" at the bottom, where it comes in contact with bottom side of radiator support, just in case, knock! I am waiting for "oil bypass" o/ring, or should I say "Quad rings" from R.C.G. They are the perfect diameter, and they are of the quad ring design. [Superior sealing.] Take Care...

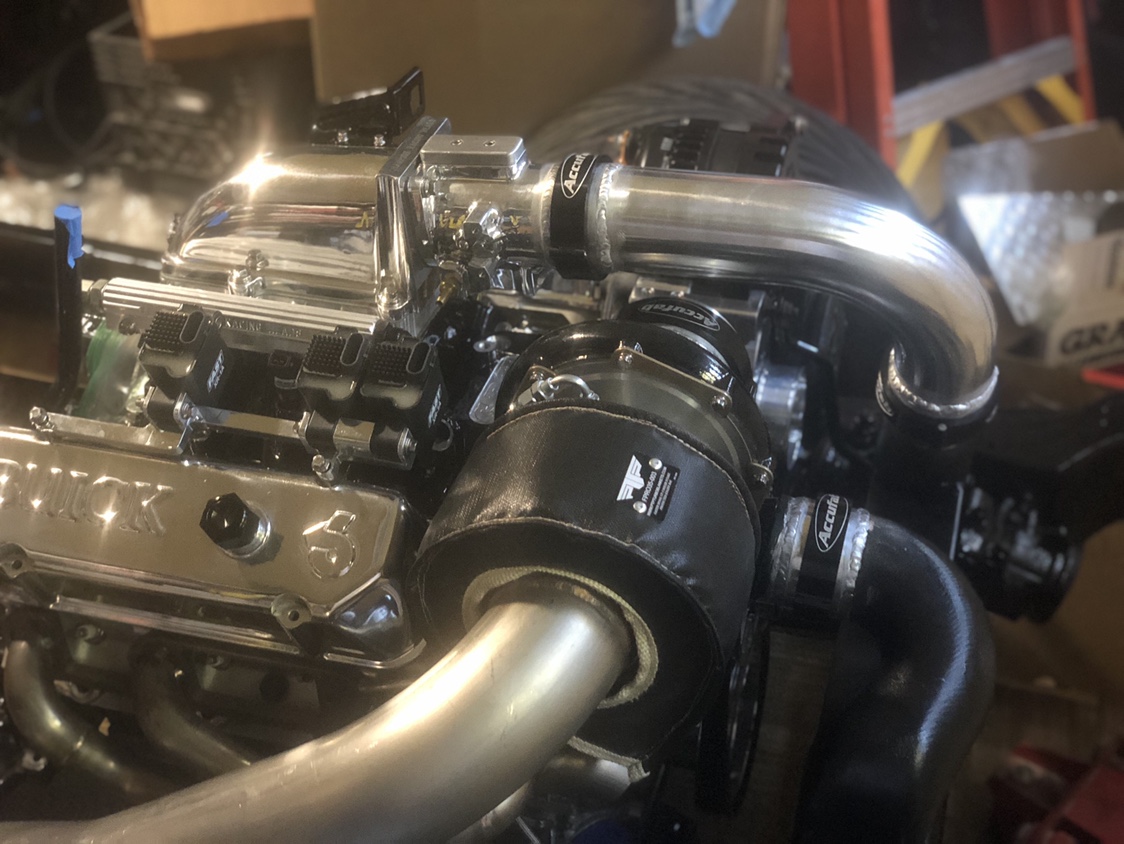

The instructions for putting in the intercooler were some of the worst I have ever seen. The parts needed to be designed with more stack up tolerancing for fitment. And you better pre insert your screws for the shroud or you will have a hell of a time attaching it. And almost always modifications to something will need to be made 90 percent of the time. But the welding and casting are nice...lolWow! I guess I'm not crazy after all. I just did "Precision stretch," and yea, it was a royal pain in the ass! Maybe because I still have "stock I.C. fan bolted to crank pulley. Did you all forget to put that on? I spoke to Precision more than once regarding installation. Sorry I don't have any pictures loaded. To begin with R.H. Aluminum bracket provided with "spacers. Holes in bracket were elongated vertically, up & down adjustment. Both spacers were cut down, in & out/tilt adjustment. L.H. "factory bracket" was also elongated vertically at attachment point to side of I.C. Attention was also given to upper mounting position, and lower as well. Where to use washers behind or in front of bracket, allowing for tilt. Keep in mind, I am still using stock I.C. fan on one side, and I have sway bar on the other. The key is to get I.C. as close as you can to an alignment of both outlets to turbo charger, as well as T.B. by way of "up pipe." Which brings to mind another "field decision." I had to use my old 21/2-inch up pipe. 3" up pipe to big at intersection of "cold air intake pipe," especially when you have 4" S- housing exhaust cover. Needed a 4" to 3" reducer cold air pipe is 3". speaking of "reducers, I needed two "offset" reducers as well. After "clocking both the "Center Section" and "exhaust Housing" so that oil feed and oil drain were parallel to the ground. And exhaust housing lined up with I.C. I still needed "offset hoses." I also found some 11/4-inch ridged clear tubing at "Home Depot." I used to wrap sway bar at contact points of I.C., just in case. It sits level. Centered with both I.C. pipes. However, is off to one side, {offset hoses.} Because it lines up horizontally, it is at the correct elevation for proper "air box" installation. I will try to upload pictures. I was told the I.C. was designed several years ago, with a different style turbo charger, maybe that accounts for the "misalignment?"

I had that. Screws were bottomed out. Tight, but not clamping the shroud at all.Does anyone else get like a tin sound rattle noise out of there shroud at idle? I can't get rid of it and everything is nice and tight. Really annoying.