- Joined

- Jun 18, 2001

- Messages

- 2,283

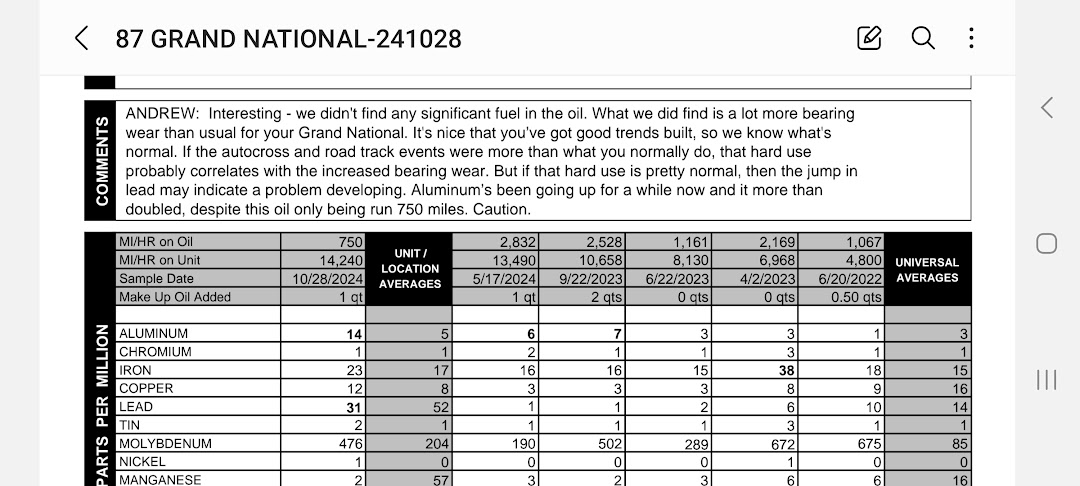

I got this oil report back after my last event of the season. Lead, copper and all the other metals spiked noticeably:

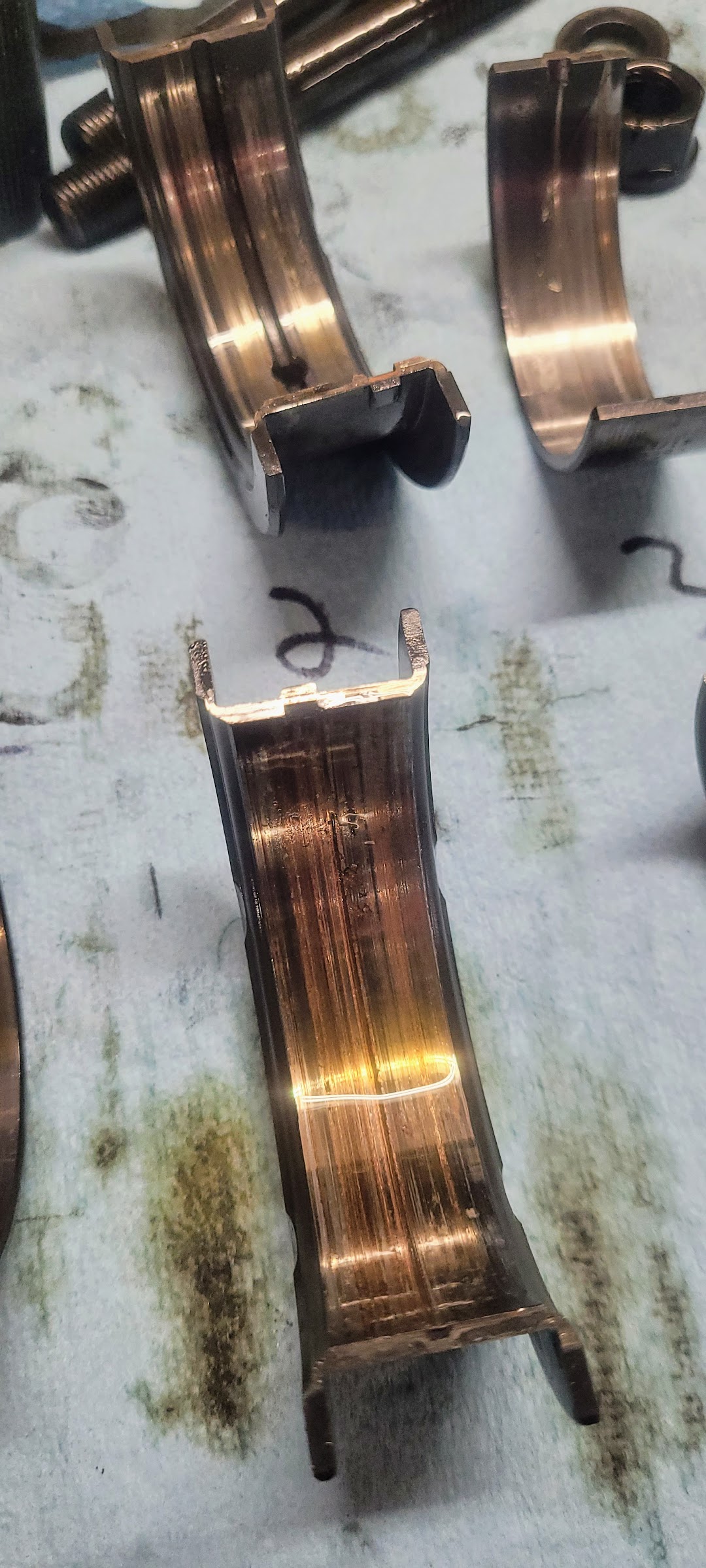

Now, there was no noise from the engine. Oil pressure was great, 80 psi+ on startup, 30 at idle warmed up. But that huge spike is a big red flag, so I dropped the pan and pulled a rod cap:

So I pulled the number 2 main cap:

Yeah, WTF?

Well, I went ahead and pulled it. First thing I noticed was the windage baffle was broken away from the oil pan on the passenger side:

Concerning, but there were no chunks missing from the fractured areas. So maybe? But let's keep looking.

The oil pump took a beating:

I found just a tiny piece of metal in the turbo filter, I think this is a symptom not a cause:

And I found several of these little chunks of something non-metallic (checked with a meter), but really hard stuck in the mesh of the oil pickup:

Pulling the oil galley plugs, and I find this:

So, the best hypothesis I have is there was way too much loctite used on these galley plugs and some chunks broke off and went through the pump and out to the mains and trashed the bearings. The debris from the bearings went through and scored the cam bearings slightly, just streaks in the teflon. But the hard parts are unharmed. The crank is beautiful, the camshaft looks perfect. A $35 lab report saved this engine. Without it it would have run just fine while those bearings continued to disintegrate and eventually something big happened.

Now instead of a pile of machine work and months of waiting since every machine shop worth a hoot is backed up at least six months I'm looking at a new front cover, carefully cleaning the block inside and out, and putting it all right back together with fresh bearings and new gaskets.

Get your stuff tested. It's cheap insurance.

Now, there was no noise from the engine. Oil pressure was great, 80 psi+ on startup, 30 at idle warmed up. But that huge spike is a big red flag, so I dropped the pan and pulled a rod cap:

So I pulled the number 2 main cap:

Yeah, WTF?

Well, I went ahead and pulled it. First thing I noticed was the windage baffle was broken away from the oil pan on the passenger side:

Concerning, but there were no chunks missing from the fractured areas. So maybe? But let's keep looking.

The oil pump took a beating:

I found just a tiny piece of metal in the turbo filter, I think this is a symptom not a cause:

And I found several of these little chunks of something non-metallic (checked with a meter), but really hard stuck in the mesh of the oil pickup:

Pulling the oil galley plugs, and I find this:

So, the best hypothesis I have is there was way too much loctite used on these galley plugs and some chunks broke off and went through the pump and out to the mains and trashed the bearings. The debris from the bearings went through and scored the cam bearings slightly, just streaks in the teflon. But the hard parts are unharmed. The crank is beautiful, the camshaft looks perfect. A $35 lab report saved this engine. Without it it would have run just fine while those bearings continued to disintegrate and eventually something big happened.

Now instead of a pile of machine work and months of waiting since every machine shop worth a hoot is backed up at least six months I'm looking at a new front cover, carefully cleaning the block inside and out, and putting it all right back together with fresh bearings and new gaskets.

Get your stuff tested. It's cheap insurance.