lnkncontiverto

Feel my Pacifists-of-Fury

- Joined

- Jun 19, 2008

- Messages

- 730

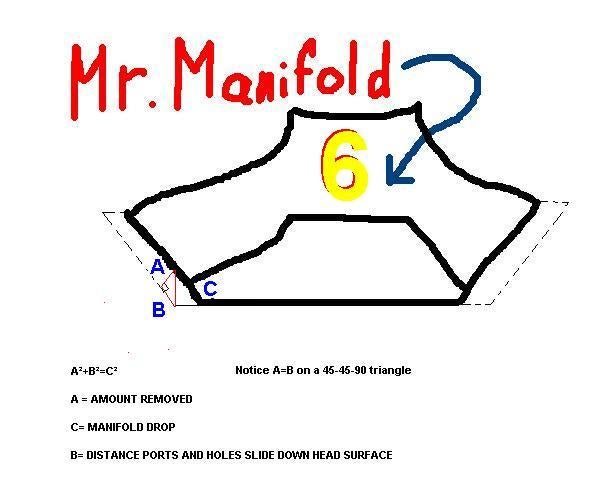

So I've installed a new set of heads that I had bought already freshened/ported. I go to bolt on my stock intake manifold yesterday and much to my chagrin, the f-in holes won't line up. I am running the Felpro 9441 HG's, BTW. Clearly the heads were shaved to true them up, which lowered them about 1/8". My question, since this is a relatively common thing to true up a set of heads, Is there anything I can do besides have my intake manifold machined down to fit?

Thanks!

Thanks!