Hi all. New motor rebuild with roller cam and adjustable rockers. Started priming with a 1/2" drill. Packed the pump with vasoline. Definitely feel the stress on the drill which tells me I'm getting pressure. At it for 5 minutes and no oil up to the heads. I pull off the left valve cover to make sure, spin the pump a few more minutes and nothing. Start to unscrew the oil filter and oil is coming out so oil is in the filter. Start to loosen the upper oil cooler line to the radiator and oil starts dripping out so I re-tighten. My fear is the engine builder forgot to put an oil gallery plug in. Am I missing something? Any and all suggestions are greatly appreciated. Thanks, andy

No oil through pushrods while priming

- Thread starter drew87gn

- Start date

Welcome!

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need more info. Did you check for oil on both sides? What casting is the block? If it's not engine in 4140 or 6109 it won't be grooved behind #1 cam bearing and will not get any oil to the left bank. Report back if you find you don't have those castings. There's a a fairly simple solution without pulling the engine

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

turbo87adam

Active Member

- Joined

- Mar 18, 2012

- Messages

- 238

Did you put a mechanical gauge on to check pressure? Also I've had a similar issue had to rotate engine in 90 degree intervals to get oil out of all 12 pushrods.

Did not check both sides. I'm trying to avoid removing the passenger side cause it's a pain to get the cover off and on with the valve cover spacers. It's a 4.1. Casting 2551429. Just took off the oil feed line to the turbo and primed. Oil came flying out. The build was done a year ago. Is it possible the assembly line got "scammer"?Need more info. Did you check for oil on both sides? What casting is the block? If it's not engine in 4140 or 6109 it won't be grooved behind #1 cam bearing and will not get any oil to the left bank. Report back if you find you don't have those castings. There's a a fairly simple solution without pulling the engine

Sent from my iPhone using Tapatalk

Did not check both sides. I'm trying to avoid removing the passenger side cause it's a pain to get the cover off and on with the valve cover spacers. It's a 4.1. Casting 2551429. Just took off the oil feed line to the turbo and primed. Oil came flying out. The build was done a year ago. Is it possible the assembly line got "scammer"?

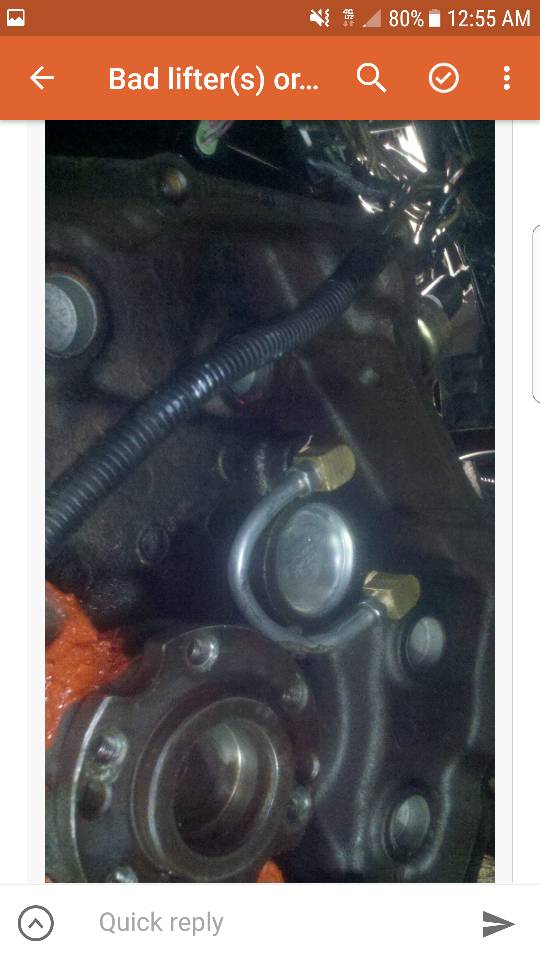

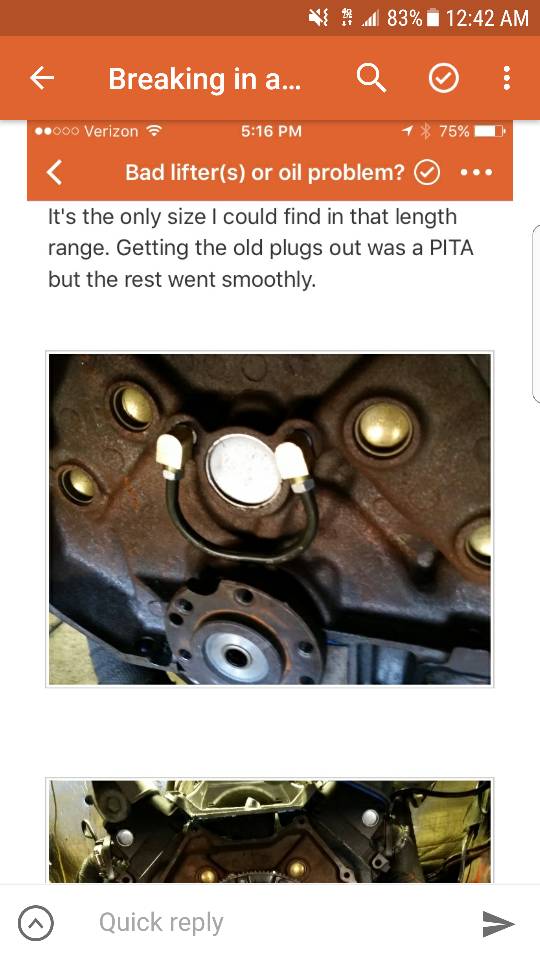

Not likely. The likely problem is there is no crossover on the #1 cam bearing. The comp cams roller cams 69-000-8 cores don't have the groove on the #1 journal. Unless a bearing or the cam was grooved you will not get oil on the left side. Remove the transmission and flexplate. Next remove the rear galley plugs and make a small jumper with 90* inverted to 1/8npt fitting and use a small inverted flared piece of nickel copper line to connect the galleys at the rear

Sent from my iPhone using Tapatalk

I have a vdo electric. With the ignition on while /upriming it reads 50 lbs. Right now the crank is set at 25 degrees so after priming was complete I could set my can sensorDid you put a mechanical gauge on to check pressure? Also I've had a similar issue had to rotate engine in 90 degree intervals to get oil out of all 12 pushrods.

So you

So you're saying I'll never get oil to the left side of I don't do this modification?Not likely. The likely problem is there is no crossover on the #1 cam bearing. The comp cams roller cams 69-000-8 cores don't have the groove on the #1 journal. Unless a bearing or the cam was grooved you will not get oil on the left side. Remove the transmission and flexplate. Next remove the rear galley plugs and make a small jumper with 90* inverted to 1/8npt fitting and use a small inverted flared piece of nickel copper line to connect the galleys at the rear

Sent from my iPhone using Tapatalk

Gene Van Horn

Active Member

- Joined

- Feb 20, 2013

- Messages

- 947

Keep,searching, there are threads with pictures of this mod done. Its alot easier than it sounds, real pita is have to pull the tranny out to do it. From what i read all the guys that did this had great results.

ek02

Well-Known Member

- Joined

- Jan 31, 2008

- Messages

- 1,226

Common problem on 4.1's with a roller cam. Either T/A rear groove cam bearings have to be used, or a passage ground in the block like a 109, or a groove machined in the front cam journal. The rear cross over tube is the easiest fix in your case.

So you

So you're saying I'll never get oil to the left side of I don't do this modification?

There's three way to get oil to the DS. Grooved cam, grooved bearing, grooved backside of bearing, grooved block (yeah, I know that's four)

If you have none of those there's no oil on that side.

Personally I like grooving the block with a Dermel tool.

turbo nasty

Turbo Dojo / MNTR

- Joined

- Jul 19, 2001

- Messages

- 9,478

Also, Galley to galley in back of block with external fittings/line.

There's three way to get oil to the DS. Grooved cam, grooved bearing, grooved backside of bearing, grooved block (yeah, I know that's four)

If you have none of those there's no oil on that side.

Personally I like grooving the block with a Dermel tool.

All of those require major work and the cam out of the engine. You can save an entire days worth of work connecting the galleys at the rear. Grooving the cam is not ideal because it reduces the bearing surface.

Sent from my iPhone using Tapatalk

VtheGNMan

Well-Known Member

- Joined

- May 19, 2014

- Messages

- 876

For someone with the block out and yet to be machined, what would the best option be? Or is there a truly better way or is it all the same, no advantage to any particular way?

Similar threads

Online statistics

- Members online

- 28

- Guests online

- 289

- Total visitors

- 317

Totals may include hidden visitors.