- Joined

- Feb 14, 2002

- Messages

- 5,873

No 3-2 control valve mod?200-4R. FYI,I use a completely stock unmodified separator plate. When my trans shifts into 3rd gear,it shows as a vertical line on my Powerlogger. I mean straight up and down.

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!No 3-2 control valve mod?200-4R. FYI,I use a completely stock unmodified separator plate. When my trans shifts into 3rd gear,it shows as a vertical line on my Powerlogger. I mean straight up and down.

With no reference to the compression ratio and open close of the valves simply adding 15-20ci to an engine via stroke won't do much at all. Plenty of stroked 3.8's out there that make a lot less than 3.4 stroke engines. Most of the Busch engines were under 3.600" stroke. 3.55-3.57" typical. Maybe they know something we don't relative to rod/stroke? Maybe it has to do with piston speed near tdc? The turbo will dictate the mass flow potential to a large degree. It's easy to say just run a couple more psi boost. Well if you have a hard running combo you are probably running as much boost as you can without losing power. The mechanical aspect of the engine is more important when trying to get increased mass flow with other limitations. Most guys on here running less than 80lbs/min of air through their engines. I doubt they are at some kind of limit. Maybe their comfort zone is breached but there's still power on the table.

Sent from my iPhone using Tapatalk

Problem is the bore spacing on these engines is inadequate for large bores which would really helpFWIW ... the most power per CID with these motors has been with a 3.07 stroke crank ... countless combinations have been built proving this.

Its also not just this particular motor .. SBF's have also found this to be true , Ive tried no less than a half dozen different variants and this is what I'm basing the statements I've made above on.

But to each their own .. if your want to spend the "EXTRA" cash on adding cubes and that makes you feel better .. go ahead ... its exactly the same scenario as porting an intake on a 11.50 car .. not gonna do anything for ya .

No. My separator plate is unmodified from its stock specs. No holes are drilled to a larger diameter. No holes are peened to make them smaller. No holes are plugged. I also have the 1-2 check ball installed.No 3-2 control valve mod?

Yes on the torque and fun,no on the sacrifice. My answer is what it is because you are mostly on the street. If you were trying for a world record,I would have a different answer. Some of us answer all questions from the perspective of a world record breaker or street car. My answer is to your question and is geared toward your personal situation. The reason you won't be sacrificing anything is because you will easily make more power than you will be able to get to the ground on the street if you go to a bigger turbo. If you continue to use your current turbo you'll have great amounts of low end torque that you will like,but your max power will still be limited by your turbo.So as I see it the stroker w some compression is gonna torque up faster than the stock stroke meaning more fun on the street w sacraficeing a bit for max hp.

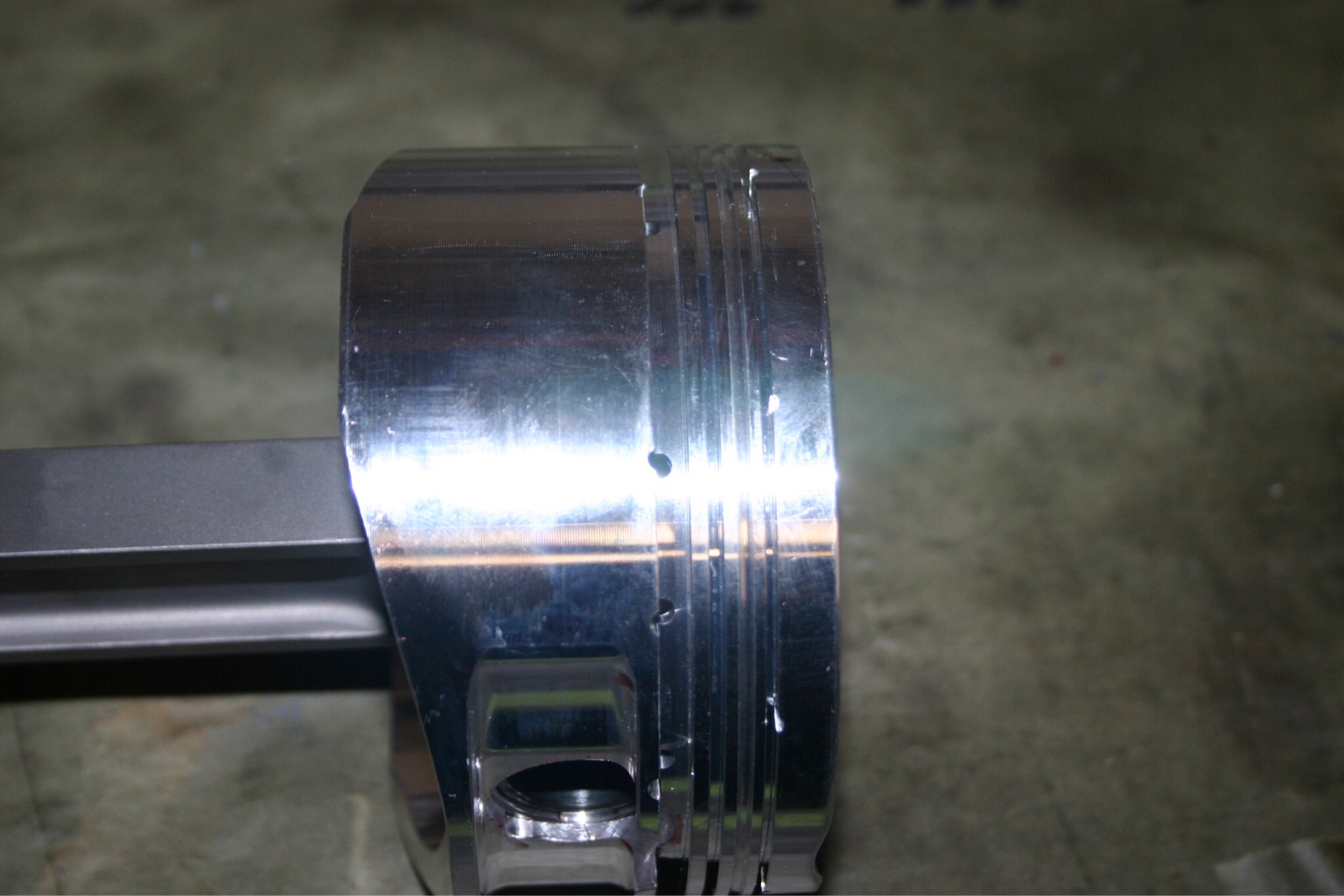

You want the pin to be as high as possible so you can have room for a good skirt that doesn't protrude too far below the bottom of the bores.What about piston life ? Isn't the pin in the oil ring ? Less skirt ?

When we stroke a Buick v6 with a 6.350" rod,the pin ends up in the oil ring.My opinion I would try and keep the pin out of the rings. I have a 6.5" rod and it reduces the piston height and makes the piston rock significantly in the bore although I have not seen any issues as of yet. I believe a more ideal rod length would be in the 6.3" range. With the good flowing heads and lower operating ranges of these engines I don't think there is any reason for a lot of piston dwell at TDC.

AG.

When we stroke a Buick v6 with a 6.3" rod,the pin ends up in the oil ring.

I don't think increasing piston dwell is a goal worth working toward in and of itself in a turbocharged engine. I would never say that I want as much dwell as possible and I'm going to do what ever it takes to get as much as possible. I do like the other thing that happens when we use a longer rod like less rod angle and less side lode on the cylinders.

With what I seen on my own stuff and the small ring package I'm running I would be surprised to see the rings in the pin on a 6.3" rod.

AG.

Wasn't trying to say that you wanted increased dwell. You clearly stated your dislike for it. I was agreeing with you.Did not imply increasing dwell is a goal working towards and in my opinion going in the wrong direction.

Wasn't trying to say that you wanted increased dwell. You clearly stated your dislike for it. I was agreeing with you.

Don't want to turn this into a knowledge contest but just stating an opinion based on what Bison and I have been developing. I have 6.5" rods and been told by some of the fastest engine builders that its less than ideal and a shorter rod would be better. If they were not Titanium and got them for a good price than I would switch over to a shorter rod. But this is just all my preference and not saying its better.Even though we have different areas of knowledge.... Guys that are doing wheelies in their sig's typically know what the eff their talking about.

I don't have my piston measurements handy but I can say based on the pictures you have that your pin is way further in the ring land than mine. I'm also running .927" pins and small metric 1.2mm/1.5mm/3mm ring pack. My pistons are about .021" in the hole based on my notes.I do use the 1/16" 1/16" 3/16" rings and the top ring is .330" down from the top of the piston. What is the distance from the top of your top rings to the bottom of your oil rings? How far down,from the top of your pistons,are the tops of your top rings?

View attachment 272367 View attachment 272368

Wasn't trying to say that you wanted increased dwell. You clearly stated your dislike for it. I was agreeing with you.

These pistons are .024" down from the deck .The deck height is 9.518".

I do use the 1/16" 1/16" 3/16" rings and the top ring is .330" down from the top of the piston. What is the distance from the top of your top rings to the bottom of your oil rings? How far down,from the top of your pistons,are the tops of your top rings?

View attachment 272367 View attachment 272368

Wasn't trying to say that you wanted increased dwell. You clearly stated your dislike for it. I was agreeing with you.

These pistons are .024" down from the deck .The deck height is 9.518".