G7 Hanger Assembly issue

- Thread starter Chevman2448

- Start date

Welcome!

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Never a bad idea to replace important hoses that are almost 30 years old. Nothing worse than blowing an engine to bits over .10 worth of hose.

I'm about to gap my CR42s into the garbage for good. I've been having some odd knock and rattling lately and the last 3 sets of brand new plugs didn't change a thing. I found an OLD set that came out of my '72 slant 6 in a bag under some mouse poop... Sanded the electrode, put them in, and the car runs better.

I think it's time for some NGK research now.

I'm about to gap my CR42s into the garbage for good. I've been having some odd knock and rattling lately and the last 3 sets of brand new plugs didn't change a thing. I found an OLD set that came out of my '72 slant 6 in a bag under some mouse poop... Sanded the electrode, put them in, and the car runs better.

I think it's time for some NGK research now.

I've been using NGKs in my motorcycles forever. It was just hard to go wrong with ACs in the Buick.... ...until recently. I'm wondering if they went the way of Delco oil filters and outsourced them without changing the part number or description.

The Radius Kid

Active Member

- Joined

- Jan 26, 2002

- Messages

- 2,596

[/QUOTE]

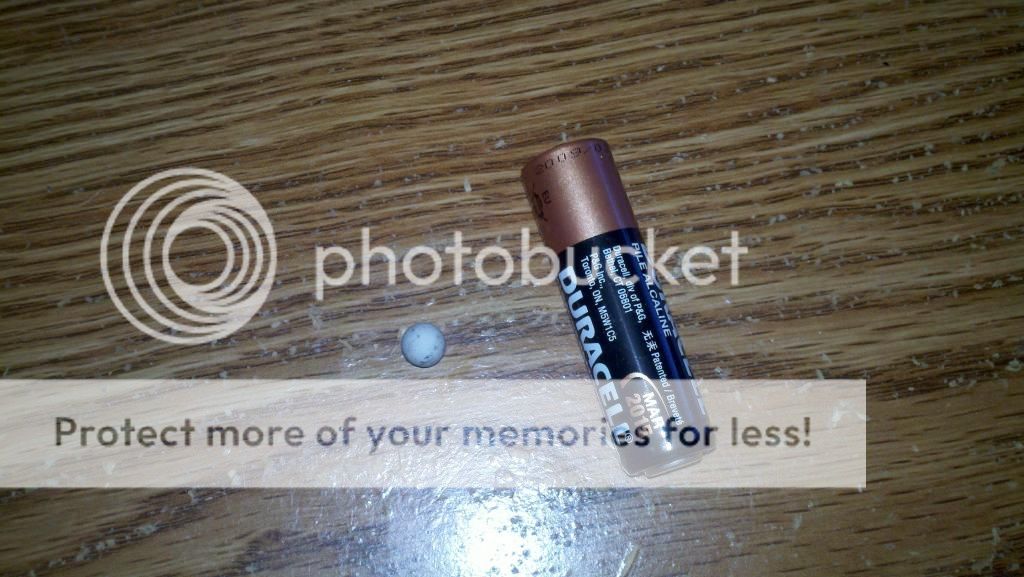

[/QUOTE]That ball is left over from the manufacturing process.

That's why it fits so tightly.

I guess they missed it,it's just a fluke.

In future the vendor *could* try blowing air through their supplied lines before cutting them up to make their kits.

That should qualify them.

Low or no flow,no go.

I've actually seen Teflon lines that had "icicles" hanging inside.

They obviously pushed the machine so fast that the inner wall couldn't solidify quickly enough to hold it's proper shape,hence the "icicles".

Last edited:

Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

Im actually using NGK's UR5's. Gapped at the factory recommended gap for a 3.8. Even though I actually have a 60 over 4.1.

Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

I checked the vacuum in the engine. It produces 22-23 inch lbs. I replaced the PVC line too after I took a closer look. The vacuum block on top of the throttle body is pretty warped but doesnt appear to be leaking, not that it still couldnt be under boost. Guess I will have to buy one of those fancy looking aluminum pieces.

Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

Well I ordered a new vacuum block. So my next question is...about the delta gate wastegates that are installed on the car. There are two wastegates. The first one is near the turbo and the other one as you will see is by the lower a-arm on the passenger side of the car.

Should there be vacuum hoses connected to these locations?

I see this one has a fitting on it already but is not connected. Does it need to be?

Should there be vacuum hoses connected to these locations?

I see this one has a fitting on it already but is not connected. Does it need to be?

Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

No one knows?

It depends on how you want to control boost. It could work with just the spring and no vacuum lines. Or you could put a vacuum line to only the bottom of each wastegate. Or you could put a line to the bottom of the wastegate and a control line (regulator or boost controller) to the top side.

If the car was tuned like that (no hoses) leave it like that.

If the car was tuned like that (no hoses) leave it like that.

Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

There are fittings on the backside of both wastegates that are connected. One is on the turbo itself and the other is on the intake tubing that goes to the intercooler. Both of the lines are connected close to each other.

There are fittings on the backside of both wastegates that are connected. One is on the turbo itself and the other is on the intake tubing that goes to the intercooler. Both of the lines are connected close to each other.

Then yours is setup to use the wastegate spring to control the boost. If it was tuned like that leave it alone. You can move the boost up or down some by moving the set screw on top of the wastegate.

If you hook a hose to the top of each wastegate directly to the intake you will have a lot of boost. When a hose is hooked to the top of the wastegate, usually there is a boost controller, solenoid or regulator in line to control it.

Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

I planned on getting a boost controller. I dont know where my boost is at yet because I havent gotten my boost gauge to work. I checked it with a compressor and it moves so there must be a leak somewhere in the system that is not allowing the gauge to read correctly. In fact it doesnt move at all. I know there is vacuum to the line because I disconnected it before starting the car. New vacuum block is coming this week so I hope that solves the issue. I can hear the turbo spool under load but still no reading on the gauge.

Thanks for the info!

Thanks for the info!

Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

Went with the Earlbrown boost controller. Im guessing the seller is the same Earlbrown that is posting on the forum.

Got my Earls -6 fitting yesterday. Hose still leaks bad. Looks like the fitting wasn't installed correctly.

Got my Earls -6 fitting yesterday. Hose still leaks bad. Looks like the fitting wasn't installed correctly.

Similar threads

3

2K

Online statistics

- Members online

- 15

- Guests online

- 12,655

- Total visitors

- 12,670

Totals may include hidden visitors.