I'm running stock lines with 120's. Low 10 af ratio 61% DC. I drilled all of the fittings. I see some turbulence occasionally on the fuel pressure reading on my Power Logger, but I think it might be the regulator. I have the 2nd pump turning on at 7psi.Do we have any good proven numbers with the Racetronix double pumpers, -8/-6 lines, stock rail, on E85 yet?

Racetronix -10 feed, -8 return???

- Thread starter jdpolzin

- Start date

Welcome!

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I don't have dyno numbers, but motor is stock except for valve springs, and ported intake and throttle body. 11.2@117 so far.I'm talking true HP numbers???

I've put quite a few E85 cars on the road for quite some time now with many different set ups but never anything making the kind of power my Stage car will put out. I'm really generalizing all cars. I'd like to know what kind of power has been made ran through these -8 feeds. I cant think of a possible number my car would make becuase I'm not the kind of guy to throw numbers out there but I'd hope for some large dyo numbers.

Racetronix

Well-Known Member

- Joined

- Oct 1, 2001

- Messages

- 1,590

I've put quite a few E85 cars on the road for quite some time now with many different set ups but never anything making the kind of power my Stage car will put out. I'm really generalizing all cars. I'd like to know what kind of power has been made ran through these -8 feeds. I cant think of a possible number my car would make becuase I'm not the kind of guy to throw numbers out there but I'd hope for some large dyo numbers.

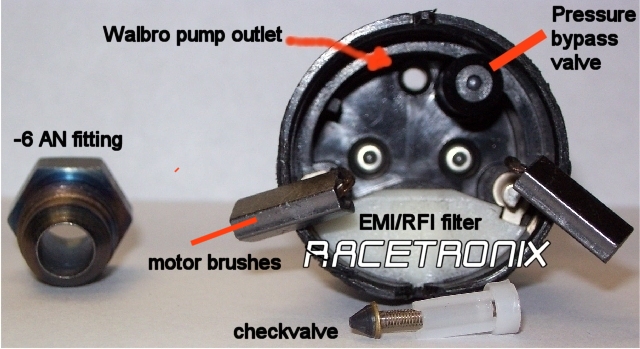

You will never get a straight answer to your question because of the question itself. It is not the lines that are the limiting factor but rather the pump's ability to produce enough head pressure to overcome line-loss and still net enough fuel volume (at the desired pressure) at the fuel rail to support your HP requirements. One must know the specifications of the pump you intend to use with the line kit to make a proper calculation. Again our FLK-G7B1 is capable of supporting our DFPS-G7A340AN DP pump assembly which flows apx. 825-850LPH @ 16V @ 43.5PSI with very little impact on flow. Unless your motor requires 1,200LPH+ of fuel there is very little to be gained by upsizing the lines. Since our DFPS-G7A340AN DP pump assembly is the highest volume pump solution we offer there is no point stocking a -10/-8 kit. We can custom make anything you want.

Let me ask what effect does the higher rail pressure of the LS engines have on the pumps? I figured at max hp i would probably run is about 1200 at the crank which according to your calculations needs 504LPH of fuel and i plan on running 15-18 psi of boost i guess the same rule applies with LS rail plus 1psi per lb of boost?

Racetronix

Well-Known Member

- Joined

- Oct 1, 2001

- Messages

- 1,590

arnt all these lines bigger than the outlet of the pumps anyway?

Yes very much so...

Racetronix

Well-Known Member

- Joined

- Oct 1, 2001

- Messages

- 1,590

Let me ask what effect does the higher rail pressure of the LS engines have on the pumps? I figured at max hp i would probably run is about 1200 at the crank which according to your calculations needs 504LPH of fuel and i plan on running 15-18 psi of boost i guess the same rule applies with LS rail plus 1psi per lb of boost?

Higher operating pressure will reduce pump volume. Factor fuel volume at maximum operating pressure.

We have a few C5/C6 Corvette customers running our dual 340LPH setup making 1200HP to the wheels at apx. 20PSI boost / 78PSI fuel pressure.

Motors at this HP level are typically supplemented with Alky injection.

Those guys making 1200whp how close to maxing out the system are they? I doubt i would ever go past that HP anyways just wondering and i don plan on Alky at this time my bost will probably not need to go past 15psi to make the power i want and most of the time it will be way lower on the street.

Racetronix

Well-Known Member

- Joined

- Oct 1, 2001

- Messages

- 1,590

Those guys making 1200whp how close to maxing out the system are they? I doubt i would ever go past that HP anyways just wondering and i don plan on Alky at this time my bost will probably not need to go past 15psi to make the power i want and most of the time it will be way lower on the street.

They are at about what we would consider their SAFE limit since there has to be a safety margin. Low voltage and hot fuel will reduce pump performance so one always has to factor in worst case scenario. TRs typically have a motor BSFC which is not as good as a LSx motor so this would be like comparing apples to oranges. Motor BSFC, required A/F @ WOT, fuel pressure, air/fuel temp, battery voltage all factor into this equation. It is not as simple as throwing a number out there.

Similar threads

3

2K

Online statistics

- Members online

- 23

- Guests online

- 2,373

- Total visitors

- 2,396

Totals may include hidden visitors.