achalmersman

Well-Known Member

- Joined

- May 28, 2012

- Messages

- 1,009

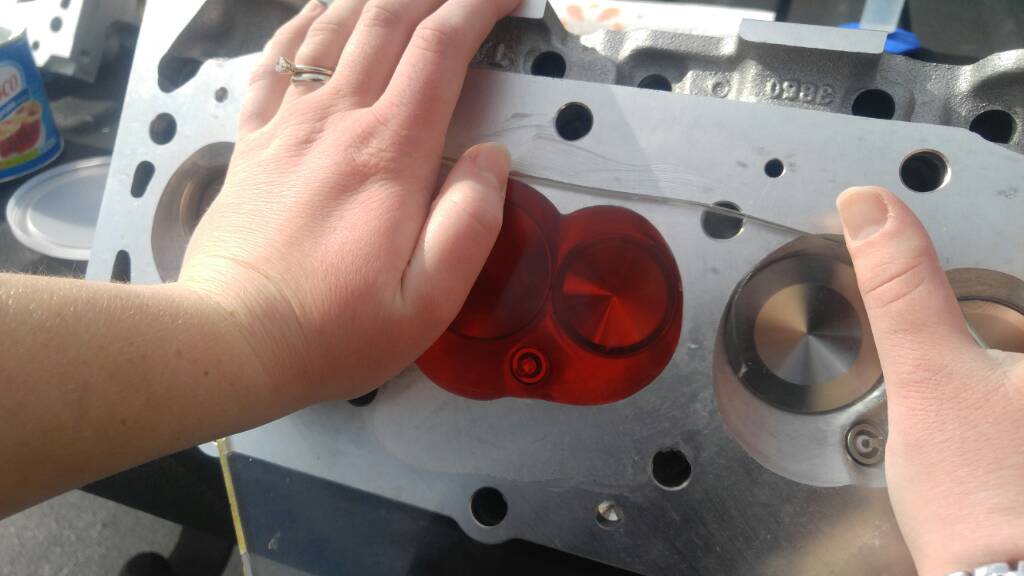

Let try this one. Taken with my real camera and touched up in lightroom

https://drive.google.com/open?id=0B07bqrn2jqr5ckgzMUVubThNMzA

https://drive.google.com/open?id=0B07bqrn2jqr5ckgzMUVubThNMzA