Just when I thought I was getting it I went confused again. Here goes. I understand that our GN's have a "return type" fuel system where essentially the computer uses the fuel it needs for load and speed and returns excess fuel to the tank while maintaining a constant pressure. (My particular 86 has the upgraded fuel pump and regulator) Well here is the area of my confusion. If the computer takes only what it needs and returns the rest, it would seem that the only mistake would be not having enough fuel pressure and, within reason, you can't have too much. And if this is so, how can increasing or decreasing fuel pressure a few pounds here or there affect a/f ratio? I'm probably just missing something here. Who can enlighten me?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel Pressure Question

- Thread starter Tom Kelly

- Start date

gunzandgearz

gearzandgunz

- Joined

- Aug 24, 2015

It's basically related to flow in other words the injector has a certain size hole or orifice in it just like you have different size drill bits you have different size orifices in the injector the bigger the orifice the more the injector will flow for a certain fuel pressure in the rail so let's say the injector is fully open and flowing the maximum it can flow at 43 PSI if I bump the fuel rail pressure up to 53 it is going to push more fuel through that injector there is a triangle formula f a p which means force is equal to area times pressure that means if you increase any of those in a hydraulic system it will increase the flow so a x p is area X Pressure so you can either increase the hole diameter (area)in the injector or increase the pressure (force)behind the injector and both will have the same effect hope that helpsJust when I thought I was getting it I went confused again. Here goes. I understand that our GN's have a "return type" fuel system where essentially the computer uses the fuel it needs for load and speed and returns excess fuel to the tank while maintaining a constant pressure. (My particular 86 has the upgraded fuel pump and regulator) Well here is the area of my confusion. If the computer takes only what it needs and returns the rest, it would seem that the only mistake would be not having enough fuel pressure and, within reason, you can't have too much. And if this is so, how can increasing or decreasing fuel pressure a few pounds here or there affect a/f ratio? I'm probably just missing something here. Who can enlighten me?

- Joined

- May 26, 2001

Based upon my experience and common sense I always want more fuel pressure rather than less.

On many GN's I have seen issues on low FP like 42-44 psi that have tip-in hesitation, stumbling and bad idle, so higher will help in many times.

Pump gas varies, race gas and e-85 need to be set where the car likes it best, adjust the fuel pressure, more or less, on a trial basis

On many GN's I have seen issues on low FP like 42-44 psi that have tip-in hesitation, stumbling and bad idle, so higher will help in many times.

Pump gas varies, race gas and e-85 need to be set where the car likes it best, adjust the fuel pressure, more or less, on a trial basis

Thanks for your response. That was the part that I understood. The part I don't understand is this: If the computer controls fuel and only takes what is demanded by load and rpm...and if any excess "flow" is returned to the tank, then it seems that it doesn't matter what the pressure is as long as its enough, coupled with injector size, to meet the demand of the computer. If it's too much pressure...or too big injector...or both.. then no harm done..excess flow is returned to the tank. If the pump is too weak..or injectors too small..or both then we have a problem. Again I am sure I am missing something.

That is what I would think. More is better. Another way to phrase my question is this: My turbotweak chip recommendation is to set fp at 43 how off and adjust as needed. So if the car runs fine, just leave it alone I guess. But what if yo set fp to say 53? Or 63? If the ecu only allows what it wants and sends the rest back to the tank, what is the harm of adding to fuel pressure?Based upon my experience and common sense I always want more fuel pressure rather than less.

On many GN's I have seen issues on low FP like 42-44 psi that have tip-in hesitation, stumbling and bad idle, so higher will help in many times.

Pump gas varies, race gas and e-85 need to be set where the car likes it best, adjust the fuel pressure, more or less, on a trial basis

gunzandgearz

gearzandgunz

- Joined

- Aug 24, 2015

Okay I think you're kind of missing the point let me see if I can explain this I think I know what you're asking the deal is a computer actually is not controlling anything on the fuel pressure or fuel flow that is all done independent from the computer it has no input on that part of it, it is being done mechanically by the pump, fuel pressure regulator ,and the size of the lines and injectors where the computers input comes in is by how much air is coming into the engine via the mass air flow sensor the computer reads that and then turns the injectors on and off if more air comes in the injectors have to be pulled on and off more times to allow more fuel in the cylinder as more air comes into the engine. you can be too small on your line lines or pump or injectors and when you get to high boost and or higher RPM the engine will demand more fuel in the system cannot provide it,on, the flip side you can have too big of injectors and where you run into a problem with this and this is what a lot of people don't understand when you get too big of an injector for your combination, its hard to control the idle fuel mixture because the injector orifices are so large that they can't keep the injector turned off long enough this is why you just want to shoot for a little larger than you need of an injector I don't know if that's exactly what you're searching for but hopefully it helps if not keep throwing the questions out

ScottHeidinger

Active Member

- Joined

- May 2, 2015

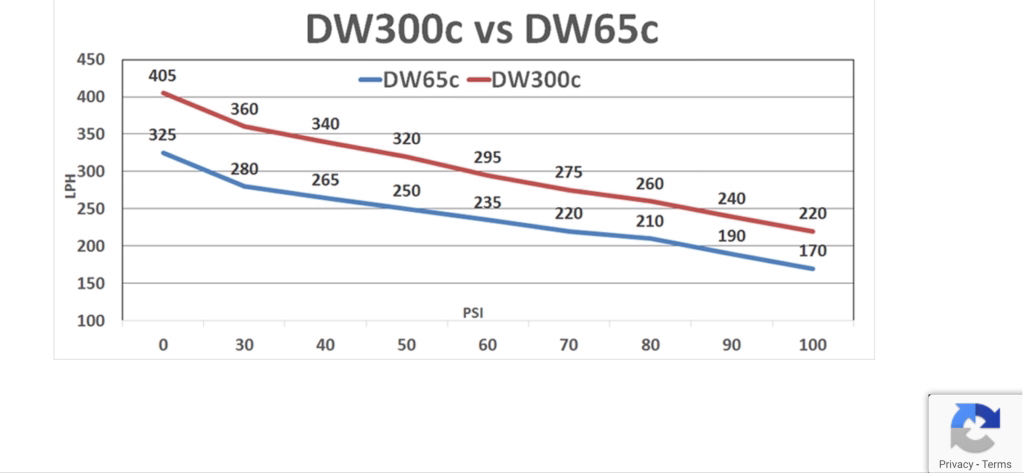

I don’t see adding a little more pressure as a issue but if you look at the flow charts as pressure increases flow from the pump decreases. The pump will also draw more current at higher pressure. Starting at 63 psi instead of 43 psi you would reduce your maximum fuel flow by about 35 liters per hour at 20 psi of boost. Some pumps don’t have a problem pushing 70 or 80 psi but others drop off in flow at those pressures and may even crap out. You can also get some big injectors that can flow more than your pump can provide and then you will see fuel pressure drop back down when you’re at high boost since the pump can’t provide the volume required to maintain the pressure. I would stay around the recommend pressure that the chip maker suggests +/- 5 psi

Sent from my iPhone using Tapatalk

gunzandgearz

gearzandgunz

- Joined

- Aug 24, 2015

Agree as the pressure in the system increases it gets harder for the pump to push the fluid through that pressure a fuel system should be treated just like your engine build all the components should be matched to horsepower and RPM demand as well as boost there are formulas out there to figure all this up I particularly like the deatschwerks fuel pumps as this is what I install in all of my hot rods if they are electronically fuel injected my personal opinion is they are the best pumps out there and there are flowcharts you can compare with the other pump manufacturers

Aha. You guys are great. I'm starting to get it. One more question that I think will cinch it for me. When You add pressure at the regulator, say go from 43 to 63 psi., how does the engine achieve that? My "doh" moment was when I realized it's not by the pump working harder. The pump flows what it flows, The pressure change happen somewhere downstream. Where? How? Also, wondering what it means by 60lb injectors. Maximum pressure?

gunzandgearz

gearzandgunz

- Joined

- Aug 24, 2015

Remember you have to separate the fuel system from the engine it is basically its own entity, as far as the pump goes a lot of people don't realize but a pump is just a fluid mover it does not create the pressure the pressure is created by the size of the lines or the orifices that the fluid flows through and this is where the pressure comes from the regulator is what controls that pressure it is basically an orifice or hole it has a bladder inside of it basically a rubber diaphragm which in layman's terms squeezes or pinches the fuel flow at that point this is what creates the pressure imagine taking your garden hose that has a spray nozzle on the end of it open the spray nozzle up all the way if I go halfway down that hose and start pinching It Off pressure behind the pinchpoint will increase correct in other words if I had a gauge on the hose and I start pinching the hose down the pressure will increase behind that pinch point that is basically what the regulator is doing in the system and what fuel doesn't get used by the engine just goes back to the fuel tank via the return line, as far as the 60 lb per hour that just means that if you open that injector all the way up in other words hundred percent duty cycle it stays open the holes or orifices in that injector will allow 60 lb of fuel to flow through it in one hour, and as far as the pump working harder they do work harder the more pressure you try to push or the more pressure that's built up in that system the pump works harder to get the fluid pushed through the system so it does work harder that's why you have to look at the pump flow charts as they will show you how much fuel that particular pump will flow or move through that particular system at a given pressure this is what separates the good pumps from the bad pumps hope this helpsAha. You guys are great. I'm starting to get it. One more question that I think will cinch it for me. When You add pressure at the regulator, say go from 43 to 63 psi., how does the engine achieve that? My "doh" moment was when I realized it's not by the pump working harder. The pump flows what it flows, The pressure change happen somewhere downstream. Where? How? Also, wondering what it means by 60lb injectors. Maximum pressure?

Helps a lot. So it's essentially finding the right balance of injector size, pump capacity and initial static pressure to make sure enough fuel is delivered. So I understand what happens if you set too much pressure. The pump will be overworked and/or not enough fuel will arrive where it's needed. So with all things being equal, does raising fuel pressure limit how much fuel can get though the "hose"? If so then why do we want fuel pressure go up when more boost is applied? You would think you would want less to provide easier flow to the injectors under high boost. So then what happens if you set too little pressure? Be patient with me. I think I am getting it.

ScottHeidinger

Active Member

- Joined

- May 2, 2015

Pumps flow a little less at higher pressure but injectors flow more with the pressure increase. The pressure rise is to increase the fuel flow thru the injector but the side effect is the pump flows a little bit less.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Got it. Actually a pretty complex dance between multiple partners. And to think all of this control used to be executed by a simple float in a carburetor bowl. Worked for years in airplanes until they went inverted. Thanks to everyone for your instruction. It has helped me understand the role of fuel pressure much more clearly.Pumps flow a little less at higher pressure but injectors flow more with the pressure increase. The pressure rise is to increase the fuel flow thru the injector but the side effect is the pump flows a little bit less.

Sent from my iPhone using Tapatalk

Jerryl

Tall Unvaccinated Chinese Guy

- Joined

- Dec 14, 2004

Fuel delivery is a function of pressure differential. At 43 psi base and 30 psi boost, the net injected presure would be 13 psi if pressure did not increase.

Raising fuel pressure effects every area of the tune, but as long as it's within the adjustment range of the ecm, it should be ok. (Target -3 to +3% change in fuel to achieve tatget AFR. Ambient temperature and barometric pressure all effect the tune.

Target AFR depends on the combo, fuel, and operating conditions. At the granular level and constant ambient conditions, actual AFR is effected by fuel, timing, distribution, voltage and plug gap, converter, and many other things.

Raising fuel pressure effects every area of the tune, but as long as it's within the adjustment range of the ecm, it should be ok. (Target -3 to +3% change in fuel to achieve tatget AFR. Ambient temperature and barometric pressure all effect the tune.

Target AFR depends on the combo, fuel, and operating conditions. At the granular level and constant ambient conditions, actual AFR is effected by fuel, timing, distribution, voltage and plug gap, converter, and many other things.

Your initial remark made it all clear to me why fp must increase with boost. What you're saying is that if my pressure is set at 43 with vacuum off, as I reach 23 psi of boost and the fuel pressure has risen to around 63, actual fuel pressure is around 40. Another epiphany. Thanks.Fuel delivery is a function of pressure differential. At 43 psi base and 30 psi boost, the net injected presure would be 13 psi if pressure did not increase.

Raising fuel pressure effects every area of the tune, but as long as it's within the adjustment range of the ecm, it should be ok. (Target -3 to +3% change in fuel to achieve tatget AFR. Ambient temperature and barometric pressure all effect the tune.

Target AFR depends on the combo, fuel, and operating conditions. At the granular level and constant ambient conditions, actual AFR is effected by fuel, timing, distribution, voltage and plug gap, converter, and many other things.

As is often the case, answering one question raises another. Continuing on the pressure differential theme, I assume it works both ways and that's why fuel pressure on the gauge drops when we re-attach the vacuum line to the regulator? But if vacuum is around 17 (which mine shows at idle) why doesn't pressure drop by 17? Does it have something to do with normal atmospheric pressure of about 14.7 psi? My particular GN experiences a drop closer to 7-8 psi when I re-attach. I do notice a drop in fuel pressure as I accelerate and vacuum drops. However I never noted what it is as vacuum turns to boost (say 1 on the boost meter) How does this all work?Fuel delivery is a function of pressure differential. At 43 psi base and 30 psi boost, the net injected presure would be 13 psi if pressure did not increase.

Raising fuel pressure effects every area of the tune, but as long as it's within the adjustment range of the ecm, it should be ok. (Target -3 to +3% change in fuel to achieve tatget AFR. Ambient temperature and barometric pressure all effect the tune.

Target AFR depends on the combo, fuel, and operating conditions. At the granular level and constant ambient conditions, actual AFR is effected by fuel, timing, distribution, voltage and plug gap, converter, and many other things.

ScottHeidinger

Active Member

- Joined

- May 2, 2015

Boost is in psi and vacuum is in In-Hg.

Sent from my iPhone using Tapatalk

ScottHeidinger

Active Member

- Joined

- May 2, 2015

Fuel pressure should raise 1:1 with boost pressure. Your static number (line off) is where it should be when it’s at the point from vacuum to boost. Fuel pressure should rise constantly as you build boost or transition from vacuum to boost. As you said it’s normal under vacuum to see fuel pressure 7 psi below static.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Thanks Scott. I missed he difference in measurement. I just converted 17 in-hg to psi and it comes out to about 8 which is just about how much my pressure drops with hose attached. And why hotter cars running lower idle vacuum drop less. (Do hot GN's indeed run lower vacuum like the hot cars did when I was a kid? Or was that a carburetor thing?)Fuel pressure should raise 1:1 with boost pressure. Your static number (line off) is where it should be when it’s at the point from vacuum to boost. Fuel pressure should rise constantly as you build boost or transition from vacuum to boost. As you said it’s normal under vacuum to see fuel pressure 7 psi below static.

Sent from my iPhone using Tapatalk

gunzandgearz

gearzandgunz

- Joined

- Aug 24, 2015

No that is a function of the camshaft I and being naturally aspirated as they have to have different cam timing the old-school carbureted cars which I work on a bunch and have had drag cars that run on carburetion what happens when you put a big cam and a mouse or rat motor the air-fuel mixture gets shoved back up into the intake manifold at idle and lower rpm because the valves are hung open longer due to more duration and more cam overlap which increases the pressure in the manifold hence dropping intake manifold vacuum

Similar threads

- Replies

- 8

- Views

- 415

- Replies

- 3

- Views

- 545