Chevman2448

Member

- Joined

- Nov 15, 2013

- Messages

- 258

First off I tried sending the manufacturer a message about this but they are not accepting private conversations on this forum. I emailed the vendor off site as well. With that stated I dont mean to belittle any manufacturer or anyone's products. For the most part the hanger assembly works electronically and fit nicely. Before I state the issue I found realize that all the fuel equipment installed on my TR is/was brand new when I purchased it (fuel lines, tank, FPR, everything). Im only bringing this to everyones attention so they look over the parts they purchase before installing.

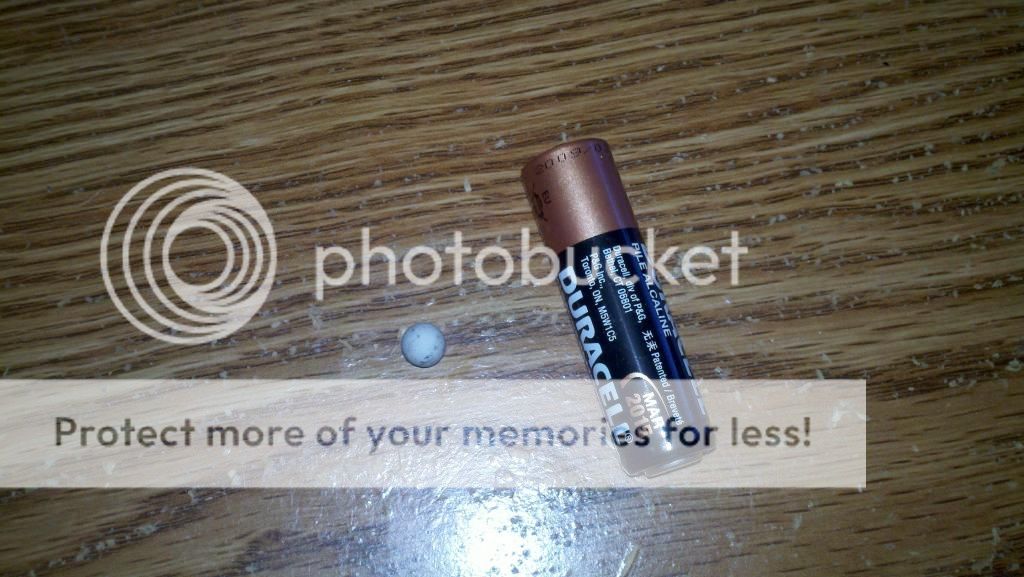

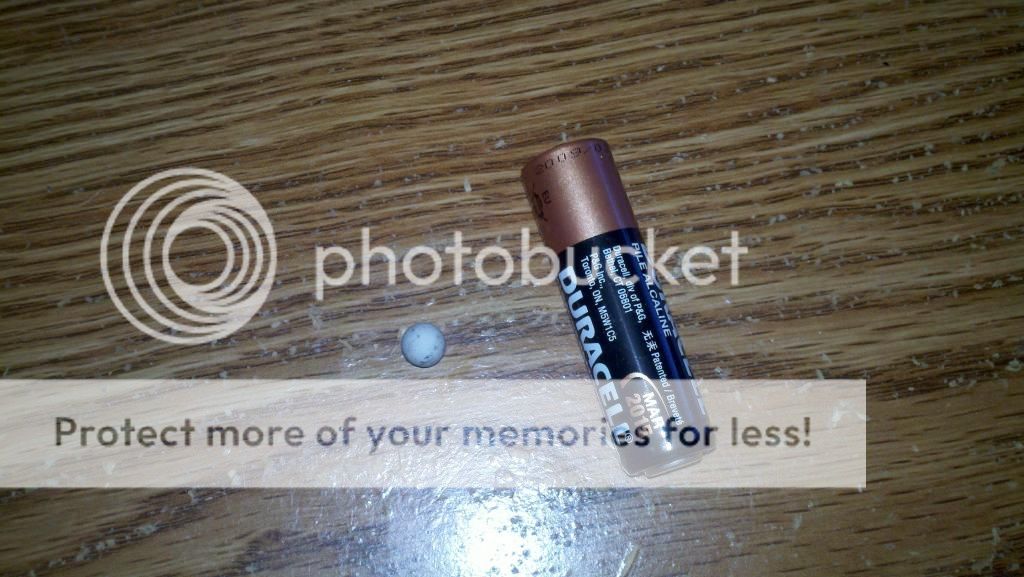

I was having fuel pressure issues with my TR. The pressure was so high that I was tearing FPR diaphragms. I installed new return lines, feed lines and all that stuff. Thinking there was an issue with my factory lines I put a -6 return line on the car. I primed the system and it had good fuel pressure. During my testing I noticed that the pressure began to spike again. Now that I know this issue has nothing to do with my fuel lines, I dropped the gas tank and pulled out the hanger assembly. I blew some air through the lines and low and behold the return line on the hanger assembly had a blockage in it. I thought, check ball? No reason for it. I unfortunately wasnt able to get a picture of it since it was actually inside the return line itself up near where the fuel level sender assembly was mounted. Ultimately I had to cut the line and put a t handle allen wrench in there and hit it with a hammer to get it out. It appears to look like a ceramic BB or a plastic BB. It was such a tight fit in the tube that there is no way it just rolled in there.

I was having fuel pressure issues with my TR. The pressure was so high that I was tearing FPR diaphragms. I installed new return lines, feed lines and all that stuff. Thinking there was an issue with my factory lines I put a -6 return line on the car. I primed the system and it had good fuel pressure. During my testing I noticed that the pressure began to spike again. Now that I know this issue has nothing to do with my fuel lines, I dropped the gas tank and pulled out the hanger assembly. I blew some air through the lines and low and behold the return line on the hanger assembly had a blockage in it. I thought, check ball? No reason for it. I unfortunately wasnt able to get a picture of it since it was actually inside the return line itself up near where the fuel level sender assembly was mounted. Ultimately I had to cut the line and put a t handle allen wrench in there and hit it with a hammer to get it out. It appears to look like a ceramic BB or a plastic BB. It was such a tight fit in the tube that there is no way it just rolled in there.