toolguy874.1

Member

- Joined

- Aug 10, 2008

- Messages

- 141

That is your decision.

I used it.

It's over 10 years old with no problems.

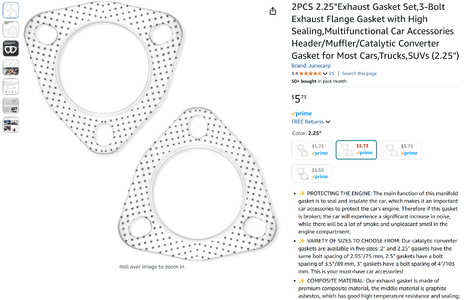

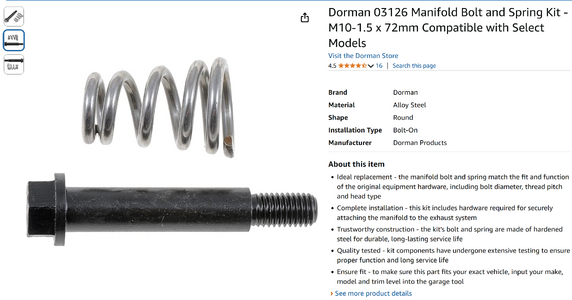

V band and flat flange gasket is a pretty precise fit.

Original has a ball socket for misalignment movement.

I used it.

It's over 10 years old with no problems.

V band and flat flange gasket is a pretty precise fit.

Original has a ball socket for misalignment movement.