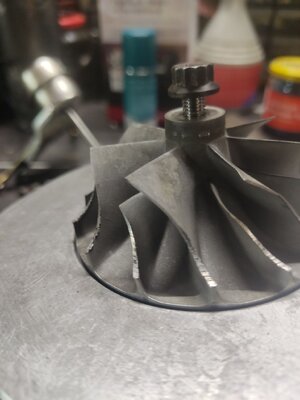

Hi Thomas, this^^^^. it's a gamechanger when either or both wheels have made contact. you will probably find the turbine wheel has back face wear contact with the "dog dish" heat shield. that said, most likely both wheels are toast. there are illustrations of such in section 6J of the GM service manual. what's not clear at this time is if there is wear to the comp cover backplate from the thrust collar. and how bad the contact grooves are to the comp cover.

Yes, there are "rebuild" kits for do-it-yourself projects when wheels are not damaged and a simple freshen-up is desired. Usually kits just contain standard size bearings, snap rings, std. 270* thrust brg, 4-piece carbon seal kit, thrust collar for comp wheel, thrust washer, and maybe some hardware and a clip for the wastegate actuator rod. if there was no wheel damage and perhaps the turbo was off-car and disassembled for cosmetic stuff ((re)coating turbine housing, bead blasting compressor housing, etc) then a major / minor kit from gpopshop could be an idea, but you're beyond that idea. for reference, see their site via link =>

G-Pop Shop

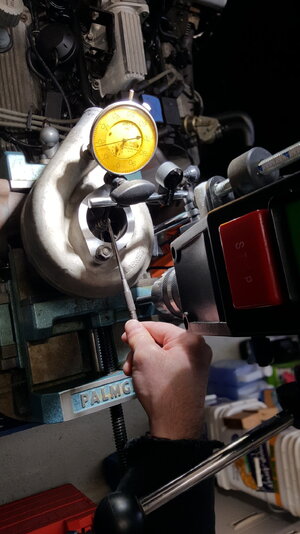

When you need a compressor wheel and most likely a turbine wheel, as mblum noted, cost to source is a consideration. getting another 60-1 compressor wheel and that turbine wheel is not a problem. A new bearing housing is readily available as are the internals. once assembled, that CHRA needs to be balanced as an assembly (VSR balancing) even though the wheel parts are balanced as individual components as new from Garrett.

some things to consider...wheel tech has greatly improved. new design MFS compressor wheels will yield better low end spooling than the old tech. And do you stick with a journal bearing unit or move to a ball bearing unit. Considering costs, maybe a wheel upgrade on a journal bearing unit would make sense.

One thing a DIY'er cannot do on their own is the 360* thrust bearing - conversion to dynamic seal (from 4-piece carbon seal) and supporting backplate to compressor cover. there is some machine work to make that adaptation to dynamic seal but it's guaranteed not to let oil pass to the compressor side like the 4-piece carbon seal can. Both Bison and Reed (Work) do this conversion automatically.

With Chopper closing the doors to Limit Engineering in Dec 2022, that leaves Bison, Reed, and PTE as noted. Patrick at PTE is a member here. with the contact to the compressor cover, I'm not sure that a scotchbrite pad can smooth out the concentric grooves caused by the wheel contact. so you might need some work done to that cover or a replacement. You have the turbine housing. If it's a Garrett .63 A/R, that is a great housing and not available new any more. Used housing from smaller turbos like factory cores are the source to be machined for the larger turbine wheel. The Garrett .63 housing is preferred over the PTE .63 housing for better spooling on a street car. Since you have at least the turbine housing, I'd consider sending turbine and compressor housing (considering picture diagnosis to both) to either Bison or Reed rather than buying a complete new unit from PTE. considering international shipping, perhaps the turbine housing could have both faces fly cut locally, if needed, blasted and refinished. something to discuss with Bison and Reed.

take a look at the youtube vids Reed has posted. let them serve as background for your conversations with both as you try to determine what wheel designs and CHRA type should be chosen for your setup. I figure you have at least a 2800 rpm stall converter for use with the old TE61. A conversation with both Bison and Reed about your complete powertrain and how the car is used might lead to a different turbo unit altogether for what you have. I expect there are plenty of turbo servicing shops in Germany....just not sure of their experience choosing something for a modified turbo Buick.

link to Work turbochargers =>

Work Turbochargers

link to Work Turbochargers on youtube=>

https://www.youtube.com/@workturbo/videos

the couple of vid's Reed has on the 5857 discuss old tech vs new tech for compressor wheels and the changes to the turbine wheel styles. that is what I was referring to above regarding what wheel designs to choose.

If you already have experience with Bison, great. for anyone reading this in the future, hopefully I've covered enough to help find a solution.