TA49 vs Precision 6262

- Thread starter Turbo Keith

- Start date

Welcome!

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Jan 18, 2011

- Messages

- 2,361

Yes that's exactly it..Might be talking about Bisons mfs 59 mm (11 blade compressor)...paired up with the taller turbine 65.

- Joined

- Jan 18, 2011

- Messages

- 2,361

65 turbine , this turbo works really well with the bottle neck stock heads, it spools like a 49 with the power of a 62#/min turbo, I really like the mis-match of wheels with shitty heads...TA cover, billet wheel, garrett .63 id bet this turbo is 10.70s on a good air motor.You may have a winner there with a billet 60 on a stock motor what size ex wheel are we talking about?

Attachments

That thing looks pretty cool.i love the 65 turbine wheel but on stock heads and low compression I would never think it would spool great I usually would go for the smallest turbine wheel I could get away with and run a tighter converter to take down the slip up top if running the 1/4,the 1/8 is a different story.i have used a 65 turbine wheel over 80lb/min on a built motor.i haven't really played with the stock stuff for max performance in a long time though and not familiar with a billet 60.i remember cast 60-1 with various turbine wheels and the the hot was a performance killer on the stock stuff if you went to big.that garret.63 is probably vital on that combo.how fast are you seeing the boost curve? At what rpm do you see max boost pressure at off the footbrake?and how many seconds from initial boost?if you don't mind me asking.65 turbine , this turbo works really well with the bottle neck stock heads, it spools like a 49 with the power of a 62#/min turbo, I really like the mis-match of wheels with shitty heads...TA cover, billet wheel, garrett .63 id bet this turbo is 10.70s on a good air motor.

49 used to surge it butt off never hurt anything though.surging seems to be part of the game when the ve sucks and you manage to get smaller turbos to spool fastI will tell you I had the same turbo from Bison and I said the SAME THING! Thought it hit harder than 6262,6266,T64,T66. Delta was on the high side were I was running it.

Didn't care for the surge at different throttle angles... That's what happens with hybrid turbos... It works great at WOT .

Would this be surging on my fast graph?49 used to surge it butt off never hurt anything though.surging seems to be part of the game when the ve sucks and you manage to get smaller turbos to spool fast

You have heads and cam.im referring to a stock motor.you will know when you have surge it's very noticeable and mainly when the turn spools fast and your really low on the throttle.just put your foot into it moreWould this be surging on my fast graph?

- Joined

- Jan 18, 2011

- Messages

- 2,361

Im running it with a 0-pump 5 disc vigilante now, use to run it with a edge racing 9.5 and it seemed to couple better down low with that, hits 26psi in less then half a second, engine was done at 5100 rpms and didn't gain anymore power after 27psi , when I had the 6262 on the same stock motor it felt like it had more torque mid range but it spooled slower and the car was considerably slower maybe .5 tenths.... I keep my wagon with an all stock long block for testing purposes then I go to my other cars with the built motors to see the differences..That thing looks pretty cool.i love the 65 turbine wheel but on stock heads and low compression I would never think it would spool great I usually would go for the smallest turbine wheel I could get away with and run a tighter converter to take down the slip up top if running the 1/4,the 1/8 is a different story.i have used a 65 turbine wheel over 80lb/min on a built motor.i haven't really played with the stock stuff for max performance in a long time though and not familiar with a billet 60.i remember cast 60-1 with various turbine wheels and the the hot was a performance killer on the stock stuff if you went to big.that garret.63 is probably vital on that combo.how fast are you seeing the boost curve? At what rpm do you see max boost pressure at off the footbrake?and how many seconds from initial boost?if you don't mind me asking.

Interesting post.sounds like the rpm window on the 62/62 was missed which is common on the stock stuff,the interesting thing to me is how the 60 billet even though bigger on the turbine side stayed in the rpm range before fall off.thats where having heads would really help even a stock cam car,I noticed it allows for more air in a narrow rpm window.Im running it with a 0-pump 5 disc vigilante now, use to run it with a edge racing 9.5 and it seemed to couple better down low with that, hits 26psi in less then half a second, engine was done at 5100 rpms and didn't gain anymore power after 27psi , when I had the 6262 on the same stock motor it felt like it had more torque mid range but it spooled slower and the car was considerably slower maybe .5 tenths.... I keep my wagon with an all stock long block for testing purposes then I go to my other cars with the built motors to see the differences..

Turbo Keith

TURBO KEITH

- Joined

- Sep 16, 2015

- Messages

- 1,671

I have noticed surging at mid throttle , I just figured it was just part of it . I may be showing my ignoranceYou have heads and cam.im referring to a stock motor.you will know when you have surge it's very noticeable and mainly when the turn spools fast and your really low on the throttle.just put your foot into it more

Noticing something is far from ignorance that's called experienceI have noticed surging at mid throttle , I just figured it was just part of it . I may be showing my ignorance

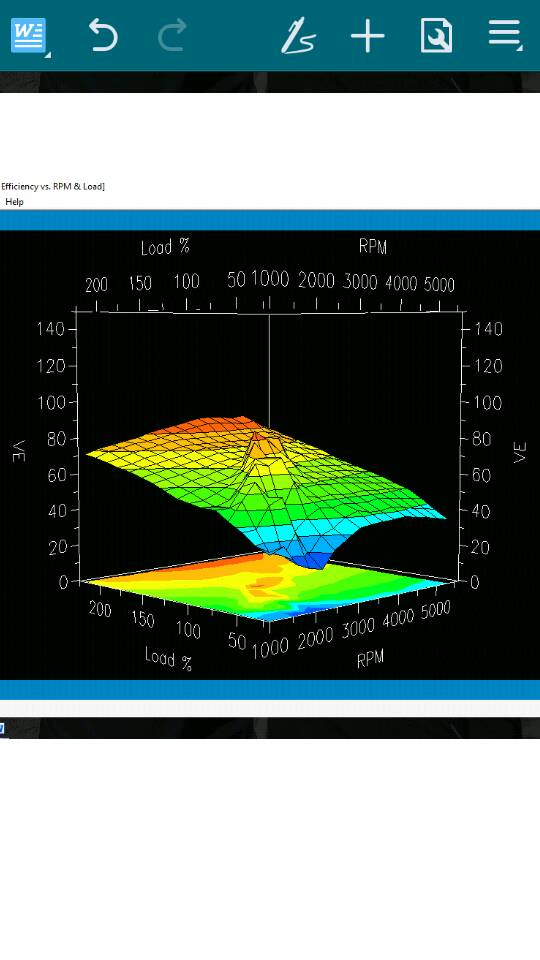

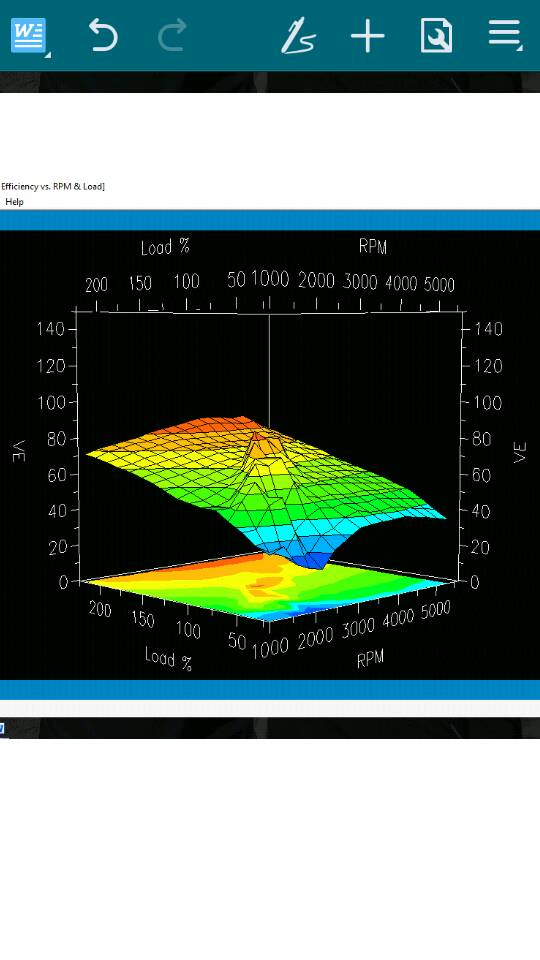

Compressor surge is not ideal.lol It's always a good idea to look at a compressor map if it's available. Anytime the pressure ratio and airflow meet to the left of the surge line, the turbo is said to be operating in surge.

Remember that's the old cast 59mm not Bisons

Remember that's the old cast 59mm not Bisons

Attachments

marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

49 used to surge it butt off never hurt anything though.surging seems to be part of the game when the ve sucks and you manage to get smaller turbos to spool fast

I spent a bit of time talking with Reed, the owner of WORK Turbo about the TA49 turbo's compressor wheel because of concerns about surging. If I can remember what he said correctly, he essentially said that the design of the TA49's compressor wheel is such that at part-throttle or low/mid-throttle, the compressor wheel does not like it and begins to surge and shudder. Adding a ported compressor cover does help this, but the compressor wheel just has a tendency to surge at part-throttle operation because of the flow dynamics of the wheel.

I don't know if that adds any insight or new information, but I figured a 20+ year veteran turbo builder like Reed would be a good person's explanation to share.

I have noticed surging at mid throttle , I just figured it was just part of it . I may be showing my ignorance

Compressor surge is not ideal.lol It's always a good idea to look at a compressor map if it's available. Anytime the pressure ratio and airflow meet to the left of the surge line, the turbo is said to be operating in surge.

Remember that's the old cast 59mm not Bisons

marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

Turbo Keith, have you tracked the car? What does it run?

Keith has taken it to the track a few times and had some good improvement, but after knowing him for a while I get the sense he is trying to take the next step up in his setup without having to touch the heads.

Now, if he was on E85...He could REALLY crank the boost up and get every last bit our of that 6262 he is looking into!

Turbo Keith

TURBO KEITH

- Joined

- Sep 16, 2015

- Messages

- 1,671

Ok , Let me clear up about going to the track . I had said in this post I haven't been to the track , But I have and the reason I said I hadn't is because this past summer I went to a local track 1/8 th mile and made a couple of passes . The best being 7.63 @ 24 lbs of Boost . I did not have a Line Lock installed , I'm doing that now , So I couldn't build any boost leaving , spinning the tires . Now please understand I AM a ROOKIE and was nervous as HELL . Yea I could have stayed and made more passes but I was not gonna beat on my car and plus it was hot as hell . I'm not gonna go to the track that much but I would like to say I have a ______ ( time slip ) fast car . So all that being said was to get back to the question ta49 vs 6262 . I was hooping a member has very close to my set up and may have had a 49 , A good 1st level upgrade turbo , and then went to a 6262 or something else and could give me some feed back if they could tell any gains or if its not worth the time or money . I have read all the post here and I do thank yall for the help and knowledge . TurboKeith

- Joined

- Jul 7, 2007

- Messages

- 484

I see you may be counting on a LineLock to help you stage and build boost...unless its hooked to your back brakes you will still have the issue you have now....may want to check out our brake/suspension section...Hydraboost will allow you to really hold in place to make boost,or...S-10 w/cyl's with long shoes adjusted properly with good tires will help a lot as well. A 2-step and or transbrake are on the list as well. Regarding your turbo questions...i did go from a 49 to a 6265JB because i KNEW i was going for a good set of head and a cam, sooner of later.... you have to ask yourself a question= are you done with your mod's? looking at you sig. i would say you have the mod-itis "bug" (boost does that) If you plan to stay where you are , and get your car to ET, you could net a mid 11 sec time card... if you think you will keep adding things...go for the 6262 or6266.or ??? You have to get a better converter to realize what any of them can ultimately do as well, as i dont see one listed in your sig. A 62 is a bigger wheel but a better design...you wont see any appreciable lag to speak of...i didnt, even with a 65 exh wheel. I suggest speaking to Bison he puts together a great turbo and his pricing is more than fair.

Turbo Keith

TURBO KEITH

- Joined

- Sep 16, 2015

- Messages

- 1,671

Hey turbocamino1 , Thanks for the feed back , I have upgraded my wheel cylinders and have the long shoes as well as Mickey T Drag radials . And yea , I got bout all the bolt on's a man could have LOL but I don't plan to take the heads off due to the factory seal , its got 74k miles and never been opened so I'm stuck , per say , with what I have . I think I'm bout to pull the trigger on a new tranny and converter . I have talked with Dusty B about one . I'm still running stock on both less a shift kit . I will be giving Bison a call as well . Momma ( Wife ) has a budget and Daddy ( myself ) has busted the shit out of it since I bought the car in late 2015 and it was stock as you could get , absolutely no upgrades . I do thank you guys for all the feedback , It is appreciated . Keith

There are plenty of wheels available now that replace the cast wheels and drop right in that will work better at higher pressure ratios with a slight drop off in max flow. The real solution is to get a good set of heads on the engine and put in a converter that can handle it. Increasing the engines mass efficiency helps a lot because the drive pressure can be lower to move the same amount or more air with the big restriction.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

BUICKTIME

It's ah me, Mario!

- Joined

- Aug 11, 2001

- Messages

- 204

Informative thread.... a lot to take in Keith.There are plenty of wheels available now that replace the cast wheels and drop right in that will work better at higher pressure ratios with a slight drop off in max flow. The real solution is to get a good set of heads on the engine and put in a converter that can handle it. Increasing the engines mass efficiency helps a lot because the drive pressure can be lower to move the same amount or more air with the big restriction.

Sent from my iPhone using Tapatalk

Bison, I'm almost ready for my Turbo.....

Similar threads

Online statistics

- Members online

- 1

- Guests online

- 5,006

- Total visitors

- 5,007

Totals may include hidden visitors.