williambavila

William Avila (The Buick Guy)

- Joined

- May 11, 2010

- Messages

- 580

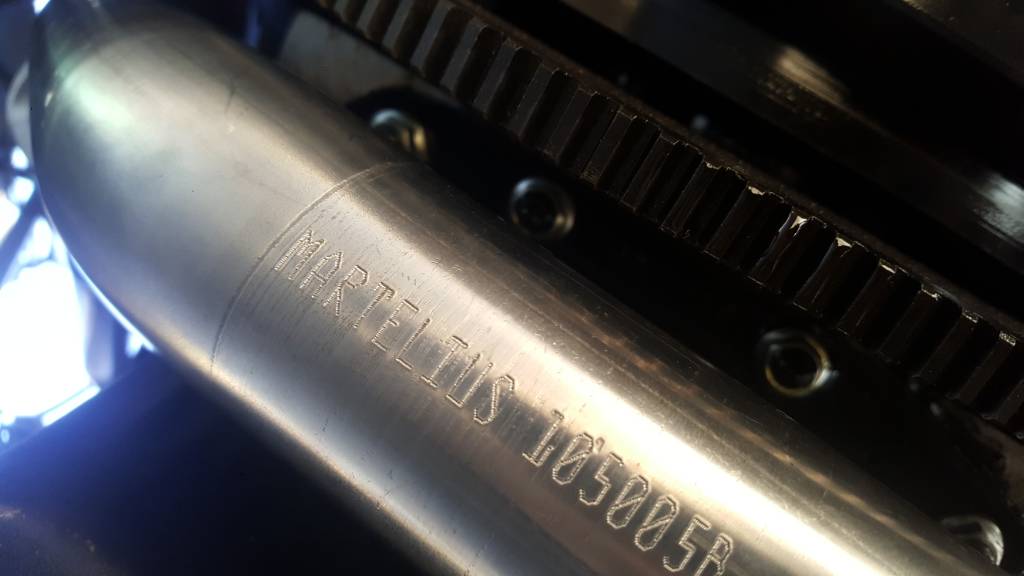

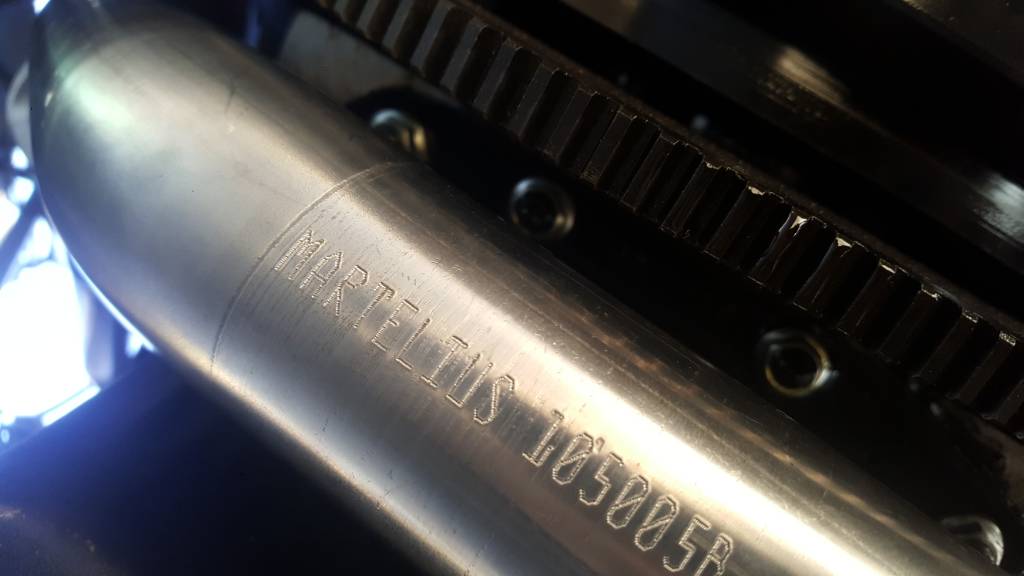

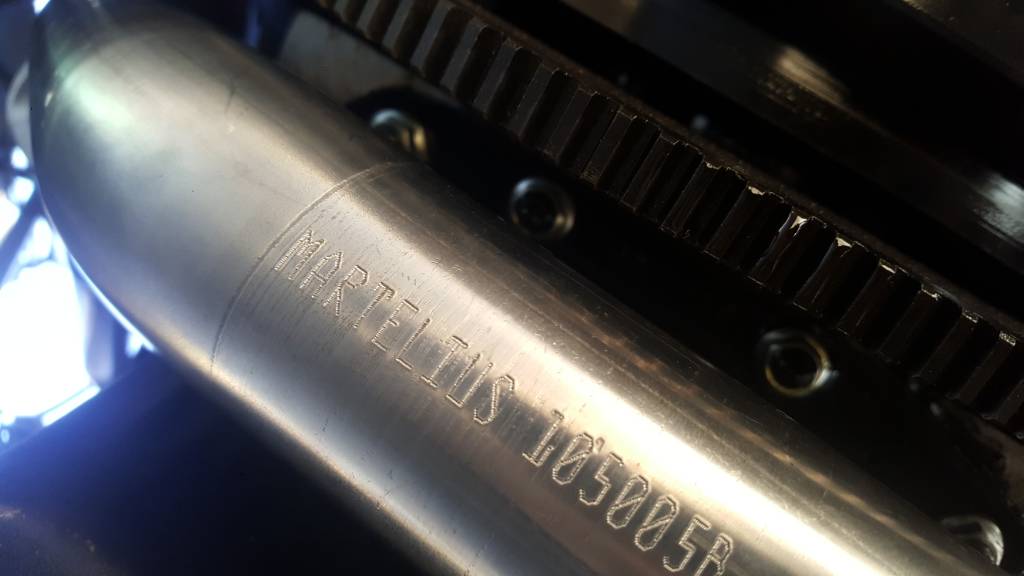

Here were the fitment issues on the headers. Drivers side flanges had to be opened up with a carbide bit at all the bolt holes.

Passenger side. Will not allow for the use of a stud due to a arm clearance.

Cross over.looked to be about 1/4" off so we installed pass side 1st clamp it tight and use a pry bar on the frame and crossover pipe from the top to pry the crossover into place.

They are on the car look great and I can't wait to use them the only other complaint is the angle at which the wastegate site. It's not at the best position for control of pressure. Here are those pics

Sent from my SM-G920T using Tapatalk

Passenger side. Will not allow for the use of a stud due to a arm clearance.

Cross over.looked to be about 1/4" off so we installed pass side 1st clamp it tight and use a pry bar on the frame and crossover pipe from the top to pry the crossover into place.

They are on the car look great and I can't wait to use them the only other complaint is the angle at which the wastegate site. It's not at the best position for control of pressure. Here are those pics

Sent from my SM-G920T using Tapatalk