My billet TA block on Methanol/E85 w/ 160lb injectors and a Gen2 'street' car build.

- Thread starter marleyskater420

- Start date

Welcome!

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This is what happens when you smoke a doobie before you start posting.. you read wayyyyy tooooooo deeeeeeeep intooooooo thinggggggsssss....I rated one of yours funny and the other agree. i have rated several posts tonight as i don't ever log into a computer to do so. i use taptalk.

Behind the safety of my keyboard, are you serious. Call me on my phone brother man i have no beef with you. if you don't want to talk to me over the phone let me know when you visit chris and ill come over and we can talk in person. You take things way to serious and maybe my posts come off the wrong way. we have talked several times over the phone before..

marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

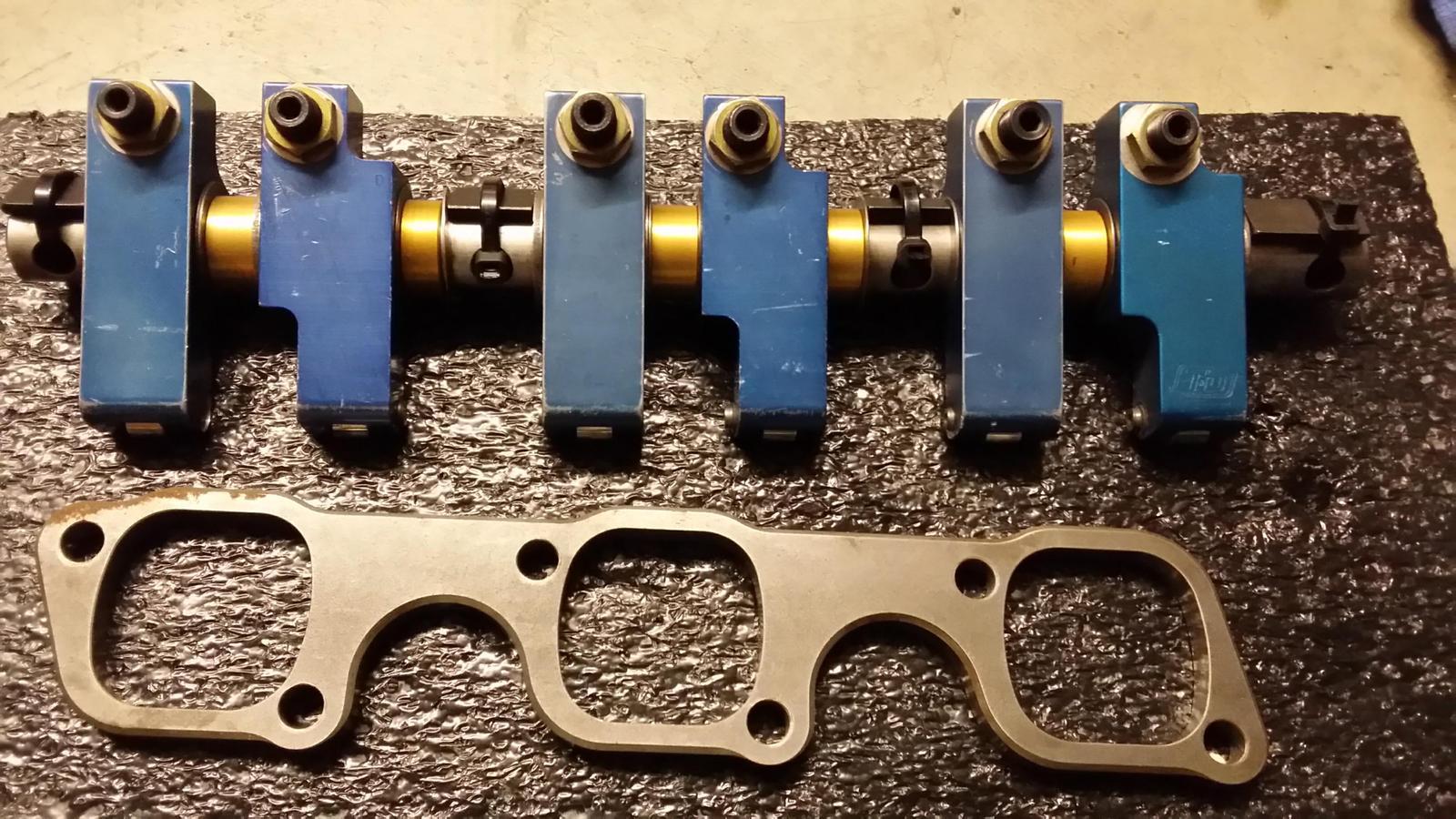

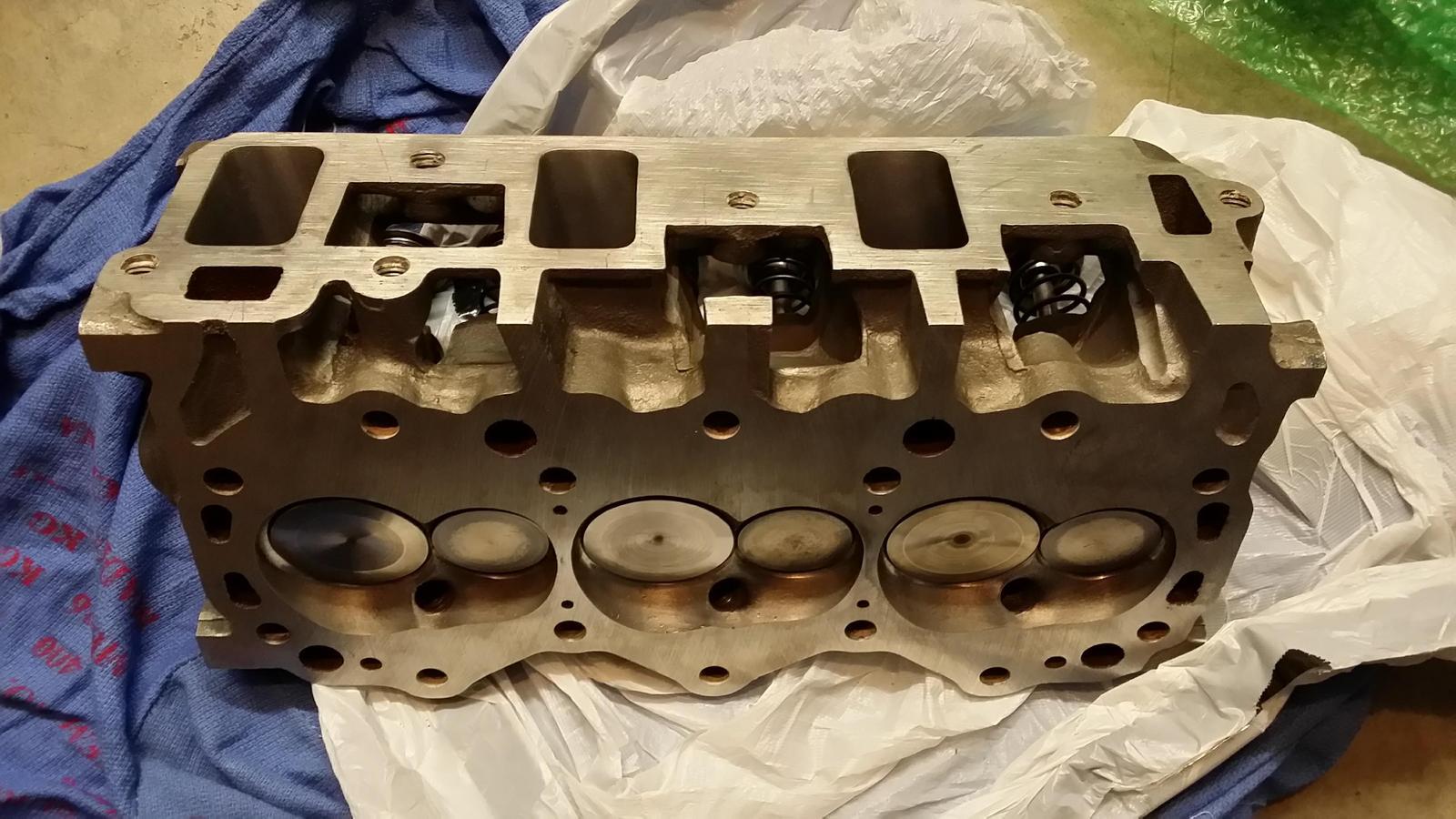

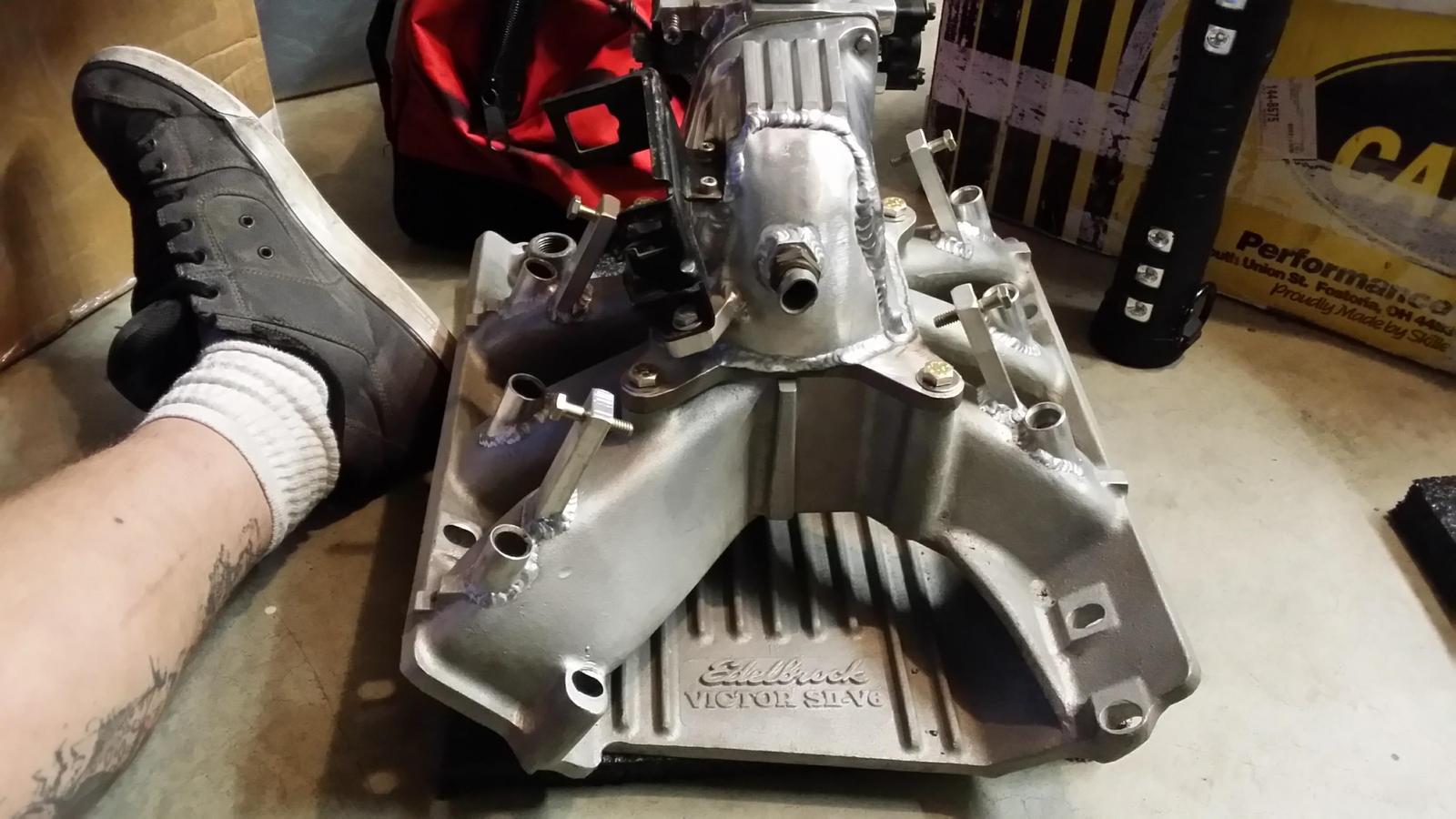

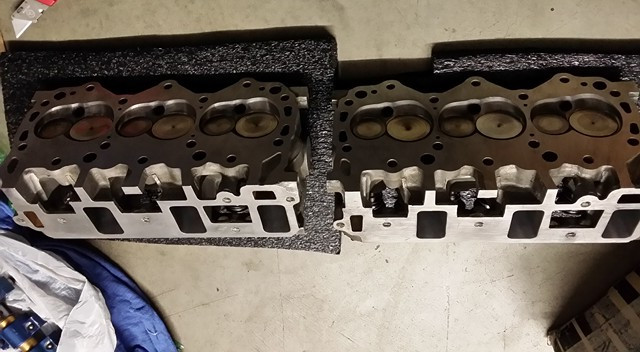

New Stage 2 top end arrived today!

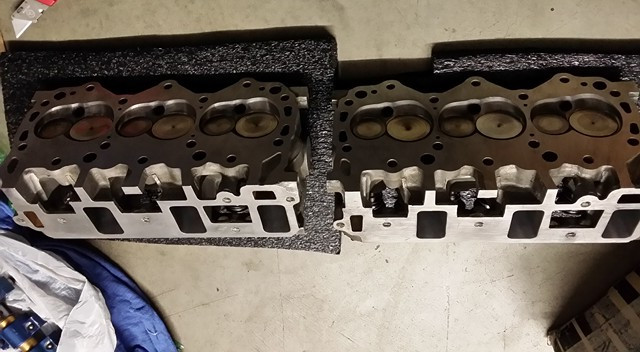

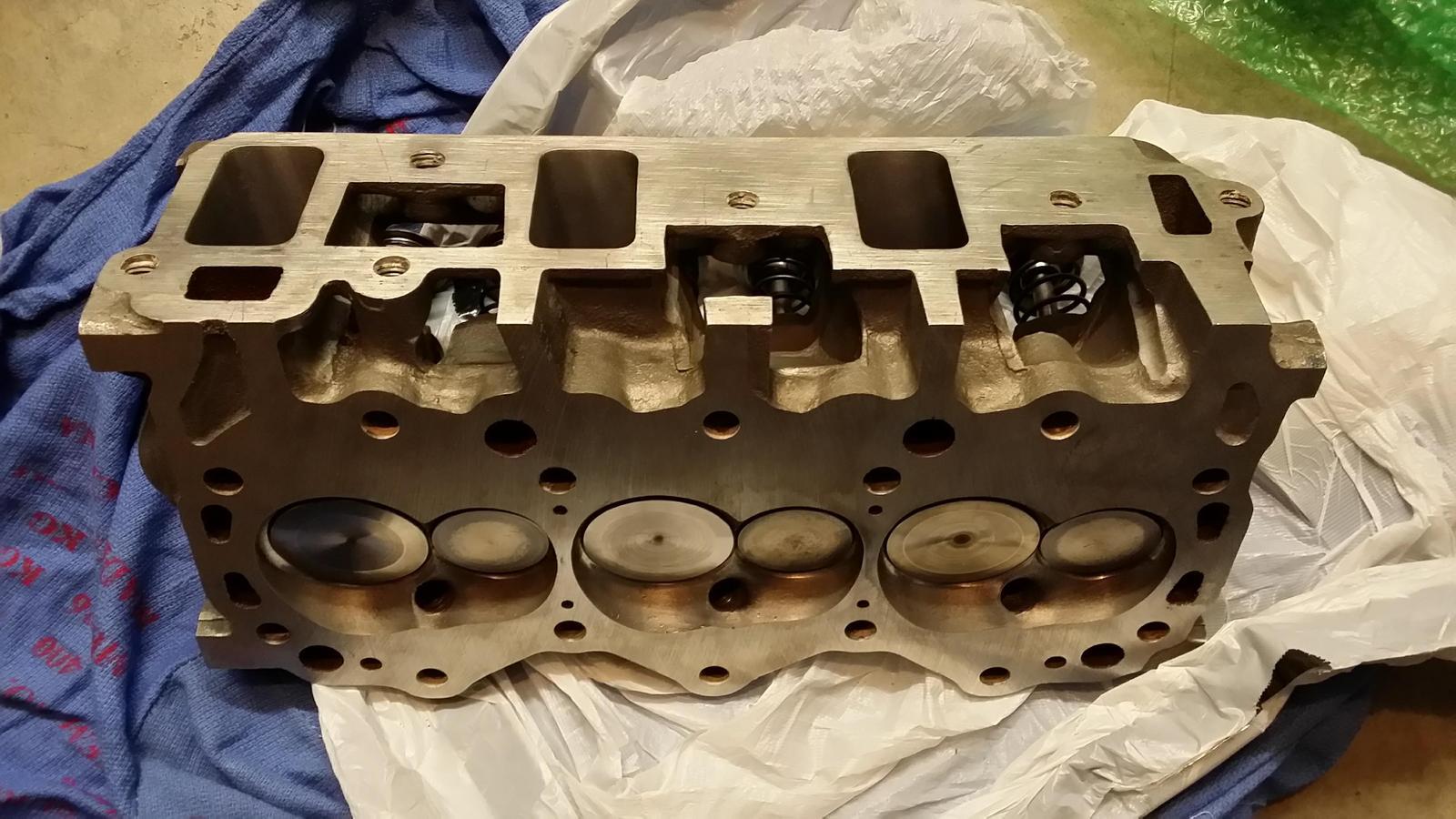

These are Stage 2 heads that were done by Chapman (NOT Champion) and has their highest level of port work done to them. These should flow around 340cfm at about .600 lift I believe.

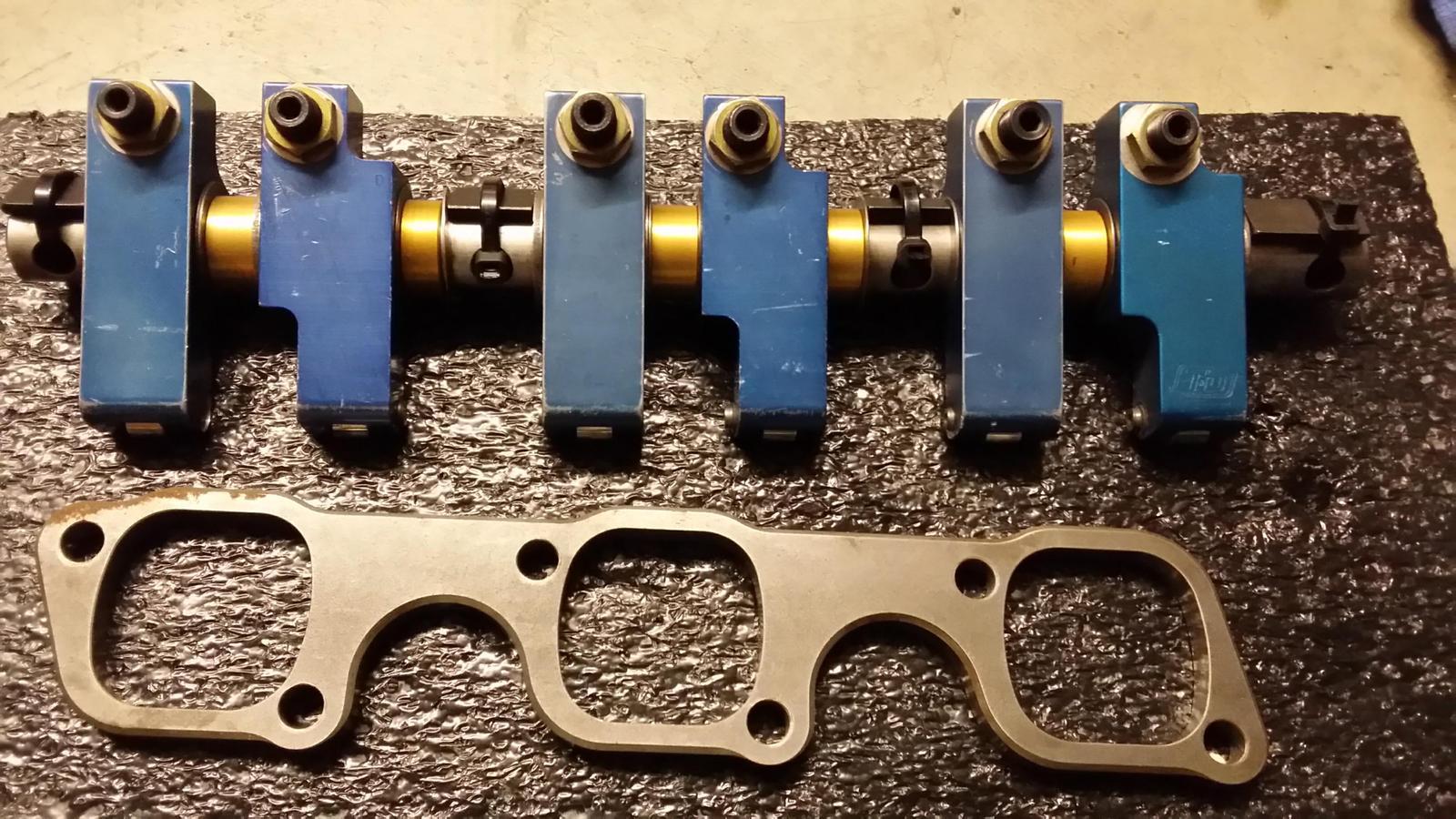

The intake has been converted from carb to efi, and the T&D rockers are staggered- the intake is 1.64 ratio and the exhaust is 1.58 ratio.

[URL=https://imageshack.com/i/pmF5M69Tj]

These are Stage 2 heads that were done by Chapman (NOT Champion) and has their highest level of port work done to them. These should flow around 340cfm at about .600 lift I believe.

The intake has been converted from carb to efi, and the T&D rockers are staggered- the intake is 1.64 ratio and the exhaust is 1.58 ratio.

[URL=https://imageshack.com/i/pmF5M69Tj]

Just read it. Will respond lil later.pm sent. dont want to take your thread off topic

You ever seen the back of a $5 bill? ....You ever seen the back of a $5 bill..ON WEED??!![/URL]This is what happens when you smoke a doobie before you start posting.. you read wayyyyy tooooooo deeeeeeeep intooooooo thinggggggsssss....

marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

So here is my attempt to explain what a twin scroll turbo is, and what twin scroll headers are.

I won't go too much into the science behind it, because there are plenty of great youtube videos that explain it incredibly well. Here is a good one:

However I will go into some detail on the subject. For more info checkout these links:

http://dsportmag.com/the-tech/twin-scroll-vs-single-scroll-turbo-test-the-great-divide/

http://www.superstreetonline.com/how-to/engine/modp-0906-twin-scroll-turbo-system-design/

Turbos have a housing that covers the compressor wheel (the compressor housing) and the turbine wheel (the turbine housing). A typical turbine housing has one inlet for the exhaust gases to enter the housing and then reach the turbine wheel. This is the "snail" looking part of the turbine housing, which can also be referred to as the "scroll". Just to be clear, you can refer to the turbine housing part that the exhaust gas travels through to reach the turbine wheel as the "scroll" part of the housing.

A twin scroll turbo is a turbo that has the turbine housing divided into two separate sections for the incoming exhaust gases to travel through (or you could say it has two separate "scrolls" for the exhaust gases to travel through to reach the turbine wheel). This means that there are two separate passageways for the exhaust gases to enter into the turbine housing. Please see the pic below that shows how the inlet to the housing is divided in the center:

This is what a twin scroll turbo looks like:

Once the air enters the turbine housing on each side, it then travels around the housing and the two passageways (or two scrolls) meet at the turbine wheel, and the exhaust gases from each side of the housing converge at the wheel and then spin the turbo. Here are some photos showing how the turbine housing is divided in the center:

In this photo you can see the tiny light pointing to a raised "lip" inside the housing. This is the divider that separates each scroll, or passageway, that the exhaust gases travel through once they enter the turbine housing:

You can see that raised "lip" in this photo as well. If you look closely you can see that below the lip there is a shadow from the light. This is the passageway / scroll, for one part of the exhaust gases to travel through. Above that lip is the passageway / scroll for the other exhaust gas to travel through.

Now onto Twin Scroll Headers...

Twin Scroll headers split up the exhaust gases coming from the engine so that each side, or bank, of the engine has the exhaust gases coming from it completely separated from the other. Meaning that the driver sides exhaust gases are completely separate from the passenger side exhaust gases. This means that the crossover pipe coming from the driver's side of the engine never meets up with the passenger side header and it remains completely separate. The crossover pipe coming from the driver's side of the engine goes all the way up to the turbo mounting flange, which is divided into two areas, just like the turbo's twin scroll housing. Here are some pics to show you how the crossover pipe from the driver's side goes all the way to the turbo flange. The pipe that goes to the top part of the flange is the pipe that the crossover pipe from the driver's side connects to:

In this photo (sorry it is blurry) the pipe on the right side is the pipe that connects to the crossover pipe coming from the driver's side of the engine:

A clear shot of how the pipes go into each side of the divided turbo mount flange:

Picture showing how the header piping is completely separate and the two pipes are independent of each other :

So why go twin scroll?

I will only briefly touch on this because as I stated above, there are many videos on youtube or links that describe the benefits very well.

The main benefits of twin scroll turbos/headers can be understood better by understanding how a non-twin scroll setup functions. In a header system that has the driver side exhaust gases meeting up with the passenger side exhaust gases (like the stock GN headers) you have all the exhaust gases mixing together and traveling in the same pathway. Now our engines fire the cylinders in a manner that one side of the engine is on the power stroke, where the other side of the engine is on the exhaust stroke, pushing out the exhaust gases into the header system.

Let's say for the sake of this example, that cylinder 1 (driver's side front cylinder) is on the exhaust stroke and pushes out the air into the headers. Now right after that let's say cylinder number 4 is just finishing up the exhaust stroke and right about to start the intake stroke, and the cylinder and camshaft have a small amount of overlap happening. (I understand this may not be the actual firing order, but this is simply to illustrate a point). So right now the exhaust gases from cylinder 1 are traveling through the headers and going through the crossover and meeting up with the passenger side collector and going up towards the turbo mount flange. At the same time cylinder number 4 is finishing the exhaust stroke and beginning the intake stroke. At this point for cylinder number 4 because it is at the moment of overlap and both the intake and exhaust valves are open, it creates a low-pressure system in the header piping.

Since high pressure always wants to find the path of least resistance, which would be a low-pressure system in this case, the exhaust gases from cylinder 1 will want to travel up the header primary and actually travel into cylinder 4's cylinder. Yes, you read that correctly - the exhaust gases coming from cylinder 1, as they travel by cylinder 4 (passenger side middle cylinder) in its period of overlap, will actually want to travel up the primary tube and go into the cylinder for cylinder 4. This means that you are getting exhaust gases going into the cylinder, taking up space inside the cylinder which means you have less space inside the cylinder to fill it with fresh cold intake air. This means now your engine displacement has just been reduced because the cylinder isn't completely full of cold air-it now is partially full of hot exhaust gases. You also lose part of your effective compression ratio since you aren't compressing only cold air.

So basically you are losing displacement, compression ratio, power, and increasing the risk of detonation because of the hot exhaust gases entering the cylinder and raising the effective air temperature inside the cylinder.

With a twin scroll configuration this is completely avoided because the exhaust gases from each side of the engine never meet. You will have no issues with exhaust scavenging or exhaust gases from a cylinder contaminating the intake charge of another cylinder that is along the pathway the exhaust gases are traveling.

I would go into more detail, but I would really recommend watching that youtube video I posted at the beginning of the post because the video has great drawings and he goes into more technical details describing the benefits.

Hopefully this helps you understand a basic understanding of what it means when we say "twin scroll" turbos or "twin scroll" headers!

I won't go too much into the science behind it, because there are plenty of great youtube videos that explain it incredibly well. Here is a good one:

http://dsportmag.com/the-tech/twin-scroll-vs-single-scroll-turbo-test-the-great-divide/

http://www.superstreetonline.com/how-to/engine/modp-0906-twin-scroll-turbo-system-design/

Turbos have a housing that covers the compressor wheel (the compressor housing) and the turbine wheel (the turbine housing). A typical turbine housing has one inlet for the exhaust gases to enter the housing and then reach the turbine wheel. This is the "snail" looking part of the turbine housing, which can also be referred to as the "scroll". Just to be clear, you can refer to the turbine housing part that the exhaust gas travels through to reach the turbine wheel as the "scroll" part of the housing.

A twin scroll turbo is a turbo that has the turbine housing divided into two separate sections for the incoming exhaust gases to travel through (or you could say it has two separate "scrolls" for the exhaust gases to travel through to reach the turbine wheel). This means that there are two separate passageways for the exhaust gases to enter into the turbine housing. Please see the pic below that shows how the inlet to the housing is divided in the center:

This is what a twin scroll turbo looks like:

Once the air enters the turbine housing on each side, it then travels around the housing and the two passageways (or two scrolls) meet at the turbine wheel, and the exhaust gases from each side of the housing converge at the wheel and then spin the turbo. Here are some photos showing how the turbine housing is divided in the center:

In this photo you can see the tiny light pointing to a raised "lip" inside the housing. This is the divider that separates each scroll, or passageway, that the exhaust gases travel through once they enter the turbine housing:

You can see that raised "lip" in this photo as well. If you look closely you can see that below the lip there is a shadow from the light. This is the passageway / scroll, for one part of the exhaust gases to travel through. Above that lip is the passageway / scroll for the other exhaust gas to travel through.

Now onto Twin Scroll Headers...

Twin Scroll headers split up the exhaust gases coming from the engine so that each side, or bank, of the engine has the exhaust gases coming from it completely separated from the other. Meaning that the driver sides exhaust gases are completely separate from the passenger side exhaust gases. This means that the crossover pipe coming from the driver's side of the engine never meets up with the passenger side header and it remains completely separate. The crossover pipe coming from the driver's side of the engine goes all the way up to the turbo mounting flange, which is divided into two areas, just like the turbo's twin scroll housing. Here are some pics to show you how the crossover pipe from the driver's side goes all the way to the turbo flange. The pipe that goes to the top part of the flange is the pipe that the crossover pipe from the driver's side connects to:

In this photo (sorry it is blurry) the pipe on the right side is the pipe that connects to the crossover pipe coming from the driver's side of the engine:

A clear shot of how the pipes go into each side of the divided turbo mount flange:

Picture showing how the header piping is completely separate and the two pipes are independent of each other :

So why go twin scroll?

I will only briefly touch on this because as I stated above, there are many videos on youtube or links that describe the benefits very well.

The main benefits of twin scroll turbos/headers can be understood better by understanding how a non-twin scroll setup functions. In a header system that has the driver side exhaust gases meeting up with the passenger side exhaust gases (like the stock GN headers) you have all the exhaust gases mixing together and traveling in the same pathway. Now our engines fire the cylinders in a manner that one side of the engine is on the power stroke, where the other side of the engine is on the exhaust stroke, pushing out the exhaust gases into the header system.

Let's say for the sake of this example, that cylinder 1 (driver's side front cylinder) is on the exhaust stroke and pushes out the air into the headers. Now right after that let's say cylinder number 4 is just finishing up the exhaust stroke and right about to start the intake stroke, and the cylinder and camshaft have a small amount of overlap happening. (I understand this may not be the actual firing order, but this is simply to illustrate a point). So right now the exhaust gases from cylinder 1 are traveling through the headers and going through the crossover and meeting up with the passenger side collector and going up towards the turbo mount flange. At the same time cylinder number 4 is finishing the exhaust stroke and beginning the intake stroke. At this point for cylinder number 4 because it is at the moment of overlap and both the intake and exhaust valves are open, it creates a low-pressure system in the header piping.

Since high pressure always wants to find the path of least resistance, which would be a low-pressure system in this case, the exhaust gases from cylinder 1 will want to travel up the header primary and actually travel into cylinder 4's cylinder. Yes, you read that correctly - the exhaust gases coming from cylinder 1, as they travel by cylinder 4 (passenger side middle cylinder) in its period of overlap, will actually want to travel up the primary tube and go into the cylinder for cylinder 4. This means that you are getting exhaust gases going into the cylinder, taking up space inside the cylinder which means you have less space inside the cylinder to fill it with fresh cold intake air. This means now your engine displacement has just been reduced because the cylinder isn't completely full of cold air-it now is partially full of hot exhaust gases. You also lose part of your effective compression ratio since you aren't compressing only cold air.

So basically you are losing displacement, compression ratio, power, and increasing the risk of detonation because of the hot exhaust gases entering the cylinder and raising the effective air temperature inside the cylinder.

With a twin scroll configuration this is completely avoided because the exhaust gases from each side of the engine never meet. You will have no issues with exhaust scavenging or exhaust gases from a cylinder contaminating the intake charge of another cylinder that is along the pathway the exhaust gases are traveling.

I would go into more detail, but I would really recommend watching that youtube video I posted at the beginning of the post because the video has great drawings and he goes into more technical details describing the benefits.

Hopefully this helps you understand a basic understanding of what it means when we say "twin scroll" turbos or "twin scroll" headers!

ttypewhite

Well-Known Member

- Joined

- Oct 1, 2001

- Messages

- 4,159

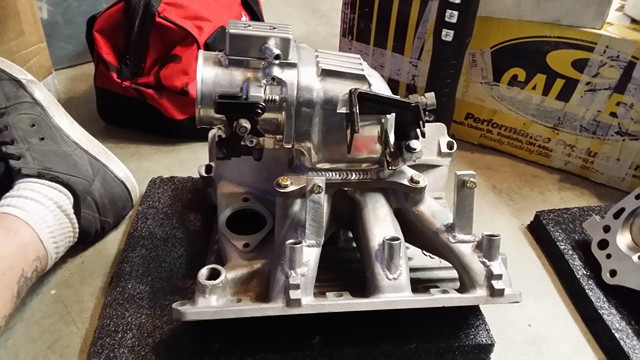

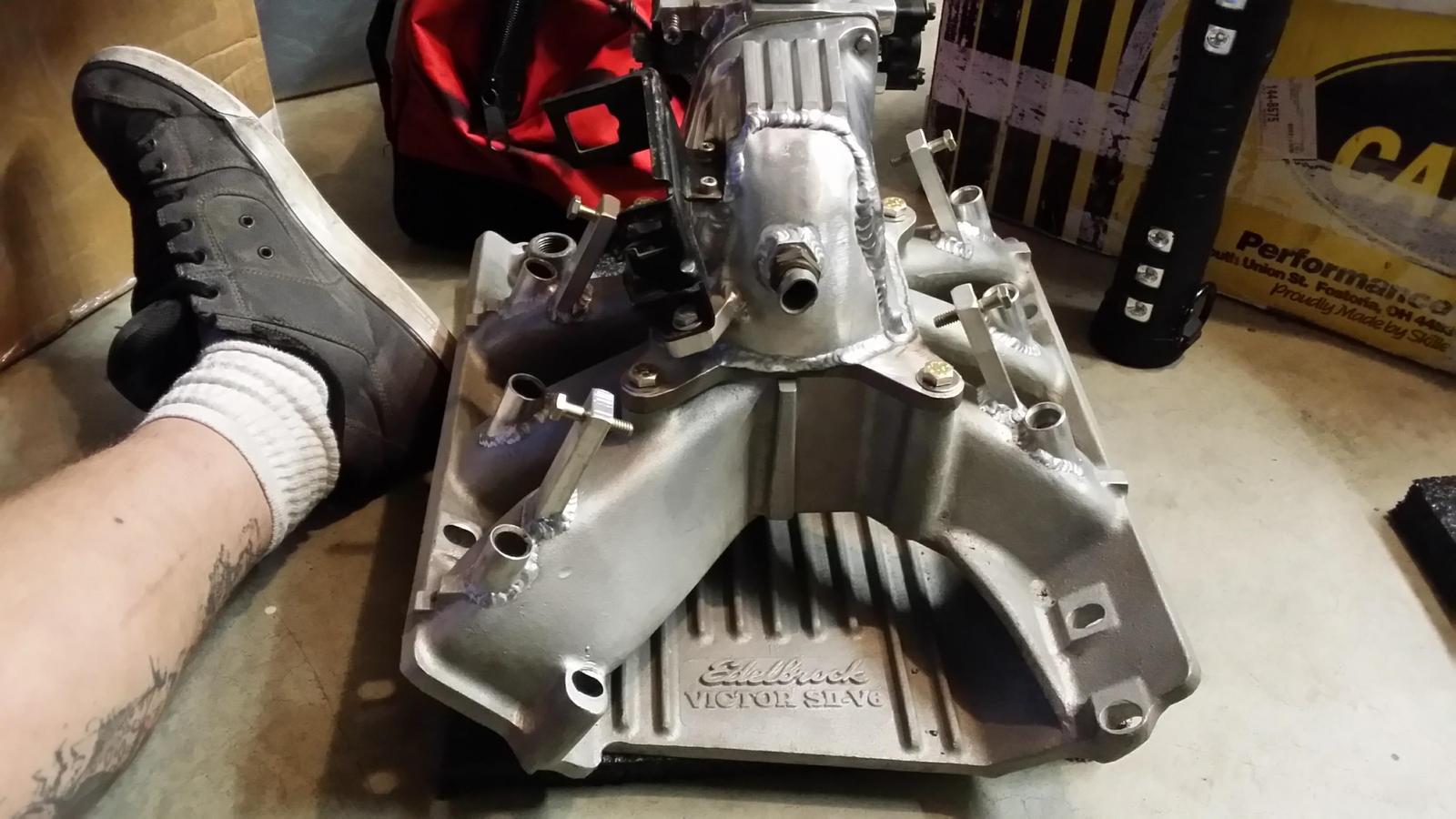

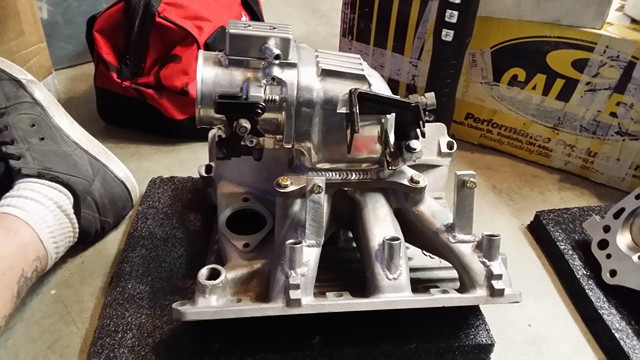

Looks good!!! Especially those headers. If it was mine, I would lose the upper plenum and throttlebody, and get a Precision bonnet and a 90mm throttlebody to properly utilize those big runners in the intake, and get better air distribution to all cylinders, and feed that with a 4" intercooler pipe. I would stick to what is proven and works with that intake manifold. That upper, even modified was design for a completely different intake with smaller runners. If your looking to make big power with it, I would change it.

marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

Looks good!!! Especially those headers. If it was mine, I would lose the upper plenum and throttlebody, and get a Precision bonnet and a 90mm throttlebody to properly utilize those big runners in the intake, and get better air distribution to all cylinders, and feed that with a 4" intercooler pipe. I would stick to what is proven and works with that intake manifold. That upper, even modified was design for a completely different intake with smaller runners. If your looking to make big power with it, I would change it.

Are you referring to my stage 2 intake?

I didn't even know Precision made a plenum for the stage 2 intakes...I've always seen a TB and custom looking plenum on top of the intake..

4" IC pipe wouldn't make sense if the IC outlet is only 3".

That's like running a -12 line feed line but a stock return line...you can only flow what the smallest size in the system lets you flow.

If I was trying to make 1,500 in my car, sure I might consider using 4" or 3.5" IC inlets and outlets, but I am using 3" because that is the size of our new FMIC's we are developing. If our new FMIC's can flow enough for 1650hp with 3" inlets and outlets, a 4" pipe wouldn't be needed..

I'm going for a reliable 9sec street car. This isn't a track car. I still don't know what you are talking about when you mention the upper plenum/manifold since this intake only has a small plenum and TB and intake... I am sorry but I am just not familiar with the Precision stage 2 intake plenum.

What other plenums work with this intake?

ttypewhite

Well-Known Member

- Joined

- Oct 1, 2001

- Messages

- 4,159

The Precision upper that I was eluding to is a universal hook up to a 4 barrel carb set up like the Edelbrock StageII lower intake that you have. Even with a 3" intercooler pipe I would still use the Precision bonnet and a 90mm throttle body, just use a step up hose from 3" to 4" to mate the 2 together.

Last edited:

marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

The Precision upper that I was eluding to is a universal hook up to a 4 barrel carb set up like the Edelbrock StageII lower intake that you have. Even with a 3" intercooler pipe I would still use the Precision bonnet and a 90mm throttle body, just use a step up hose from 3" to 4" to mate the 2 together.

Werd. I'll look into that for sure.

Thanks for the heads up.

I'm actually working with Bell intercoolers to design a new 1600hp FMIC for these cars that requires little modifications, and another 1100hp core that requires zero mods.

When those are done I'll be posting pics, and see if I can get some 4" piping made for mine, as long as it clears the MAF pipe.

hemi8

Goin Sideways

- Joined

- Jun 6, 2001

- Messages

- 1,030

Also as an option you could send your intake setup to Wilson Racing Intakes and have them install their plenum and 90mm TB. They could fabricate the throttle linkage bracket for you to make for an easy hook-up. Since you have the heads off they might want those sent in as well for port matching. Anyways it would be a very professional job.

Glad to see you are going to install the proper S2 heads, try not to get your foot stuck in the ports.

Mike

Glad to see you are going to install the proper S2 heads, try not to get your foot stuck in the ports.

Mike

Mike Licht

I was here first

- Joined

- May 23, 2001

- Messages

- 4,642

the precision elbow is here https://www.precisionturbo.net/air-...Forward-Facing--90�-Angle-for-4150-Flange/413 the holley one is nicer in my opinion and drilled for vacuum plus is priced really well. https://www.holley.com/products/fue...bodies/throttle_body_components/parts/300-240

edelbrock also makes a nice one, so does Wilson. some of the throttle bodies are now made with a v band or quick release style clamp that can be welded to the intercooler pipe and eliminate a hose connection. hope that helps

edelbrock also makes a nice one, so does Wilson. some of the throttle bodies are now made with a v band or quick release style clamp that can be welded to the intercooler pipe and eliminate a hose connection. hope that helps

Turbo Keith

TURBO KEITH

- Joined

- Sep 16, 2015

- Messages

- 1,671

I need an update Tyler , When are you gonna lite that BEAST of yours ? I cant wait to see it , Keith

SpeedRacerX

Well-Known Member

- Joined

- Jan 20, 2014

- Messages

- 1,079

Has anyone seen or heard from Tyler in the last 2 days? I ordered and paid for a Work turbo from him two days ago - I have emailed and texted but no reply. Nada. I truly hope he is ok.

- Joined

- May 28, 2001

- Messages

- 2,566

I will check on him. I needed to talk to him too.

Randy PM me the details on your order, I can check with Reed on it as well.

Randy PM me the details on your order, I can check with Reed on it as well.

- Joined

- May 28, 2001

- Messages

- 2,566

We are working on his project too.I need an update Tyler , When are you gonna lite that BEAST of yours ? I cant wait to see it , Keith

We will be taking lots of video from dyno runs and posting it up here and on RPS as well.

SpeedRacerX

Well-Known Member

- Joined

- Jan 20, 2014

- Messages

- 1,079

I've talked to Reed. Awesome guy. He knows my order details. Reed is waiting on my Buick housing core but I'm not sending out a core to Reed directly until the guy I paid confirms. Last thing I need is for Reed to spend time on this, not get paid by Tyler and then my turbo gets held for ransome until someone pays Reed.I will check on him. I needed to talk to him too.

Randy PM me the details on your order, I can check with Reed on it as well.

I may be over thinking this but crazy stuff happens and this is my first time trying Tyler. Tyler and I communicated heavy for a week or more and as soon as I ordered...darkness.

I'm hopeful this will work itself out soon.

Sent from my SAMSUNG-SM-G900A using Tapatalk

SpeedRacerX

Well-Known Member

- Joined

- Jan 20, 2014

- Messages

- 1,079

I'm happy to report I heard from Tyler and he is ok.

Sent from my SAMSUNG-SM-G900A using Tapatalk

Sent from my SAMSUNG-SM-G900A using Tapatalk

marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

Hey Guys,

My Mom just dropped my laptop off to me in the hospital.

I'm sorry I've been gone and non-responsive. I wokeup Monday and had to be rushed to the hospital. I had a disk in my spine (which I am already getting treatment for) swell up and cause me to be unable to move.

I've been in and out of consciousness the last three days as my disk returns back to normal. I should be out of here later tonight, if not tomorrow.

And if I am acting kinda weird, these pain meds are pretty damn awesome

My Mom just dropped my laptop off to me in the hospital.

I'm sorry I've been gone and non-responsive. I wokeup Monday and had to be rushed to the hospital. I had a disk in my spine (which I am already getting treatment for) swell up and cause me to be unable to move.

I've been in and out of consciousness the last three days as my disk returns back to normal. I should be out of here later tonight, if not tomorrow.

And if I am acting kinda weird, these pain meds are pretty damn awesome

marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

the precision elbow is here https://www.precisionturbo.net/air-fuel-delivery/plenum-adapters/details/Precision-Turbo-and-Engine-Plenum---90mm--Forward-Facing--90�-Angle-for-4150-Flange/413 the holley one is nicer in my opinion and drilled for vacuum plus is priced really well. https://www.holley.com/products/fue...bodies/throttle_body_components/parts/300-240

edelbrock also makes a nice one, so does Wilson. some of the throttle bodies are now made with a v band or quick release style clamp that can be welded to the intercooler pipe and eliminate a hose connection. hope that helps

Thanks Mike.

Who sells a 90mm throttle body?

That Holley unit looks nice. I might go with that, although we have a remote vacuum block setup in the works, so I'd now have to test those parts on a customer's car before we released it for sale.

I need an update Tyler , When are you gonna lite that BEAST of yours ? I cant wait to see it , Keith

Hey Keith,

I plan on dropping my motor off to Duttweiler's before summer starts. We have already spoken with Duttweiler and Reggie, Chris, and myself plan on renting the dyno from Duttweiler for a day to test a bunch of turbos and see how much power our custom billet rods and my SCAT crank can hold.

Reed from WORK turbo has already said he will be building us 2 or 3 custom turbos to run on my engine to showcase how much power his turbos really can produce. We might even have some Comp turbos to compare them to as well

I've talked to Reed. Awesome guy. He knows my order details. Reed is waiting on my Buick housing core but I'm not sending out a core to Reed directly until the guy I paid confirms. Last thing I need is for Reed to spend time on this, not get paid by Tyler and then my turbo gets held for ransome until someone pays Reed.

I may be over thinking this but crazy stuff happens and this is my first time trying Tyler. Tyler and I communicated heavy for a week or more and as soon as I ordered...darkness.

I'm hopeful this will work itself out soon.

Sent from my SAMSUNG-SM-G900A using Tapatalk

Hey Randy,

We already spoke today, but I just want to clarify for anyone else that missed it- I was in the hospital for the last 3 days, which is why I didn't respond.

Your turbo is ordered and I will get you confirmation from Reed once I receive it

SpeedRacerX

Well-Known Member

- Joined

- Jan 20, 2014

- Messages

- 1,079

Thanks Tyler. I shipped my core to Reed last night. He'll have it Tuesday.Thanks Mike.

Who sells a 90mm throttle body?

That Holley unit looks nice. I might go with that, although we have a remote vacuum block setup in the works, so I'd now have to test those parts on a customer's car before we released it for sale.

Hey Keith,

I plan on dropping my motor off to Duttweiler's before summer starts. We have already spoken with Duttweiler and Reggie, Chris, and myself plan on renting the dyno from Duttweiler for a day to test a bunch of turbos and see how much power our custom billet rods and my SCAT crank can hold.

Reed from WORK turbo has already said he will be building us 2 or 3 custom turbos to run on my engine to showcase how much power his turbos really can produce. We might even have some Comp turbos to compare them to as well

Hey Randy,

We already spoke today, but I just want to clarify for anyone else that missed it- I was in the hospital for the last 3 days, which is why I didn't respond.

Your turbo is ordered and I will get you confirmation from Reed once I receive it

Sent from my SAMSUNG-SM-G900A using Tapatalk

NY Twin Turbo

All the good stuff.....Times 2.

- Joined

- Dec 10, 2014

- Messages

- 2,877

Tyler, I'm using an Acufab Ford style 90mm. It doesn't have a vacuum block and you need to use the ford style TPS. An IAC adapter must be used as well. And if you want the throttle cable on the passenger's side, you must flip it upside down.Thanks Mike.

Who sells a 90mm throttle body?

That Holley unit looks nice. I might go with that, although we have a remote vacuum block setup in the works, so I'd now have to test those parts on a customer's car before we released it for sale.

See below.

Attachments

Similar threads

16

985

11

6K

Online statistics

- Members online

- 11

- Guests online

- 5,113

- Total visitors

- 5,124

Totals may include hidden visitors.