So I thought it might be helpful to take some time and do a write-up / tech article about the differences in todays "billet" compressor wheels that we see on turbos.

With such large discrepancies in pricing between certain turbo manufacturers, and even within manufacturer's own various lines of turbochargers, I think it would be helpful if all of us really knew what we were paying for (or

not paying for, in some instances) when we buy a company's turbocharger.

This post is essentially a compilation of information available from the following websites/sources:

*

https://www.cartechbooks.com/techtips/anatomy-of-a-turbocharger-whats-inside-and-how-it-works/

*Cabo Turbo Technologies

*KTS Turbochargers

*

https://www.mpturbos.com/development.html

*

https://blog.steamspeed.com/2014/11...ed-vs-blouch-vs-forcedperformance-vs-garrett/

*

http://www.enginebasics.com/Advanced Engine Tuning/Billet vs Cast Wheels.html

I will break this post into three parts:

1) Cast vs. Billet Compressor Wheels, and the various types of Billet Compressor wheels

2) Some of the new technologies used in newer billet compressor wheels, and Flank vs. Point-milling in Compressor Wheels

3) How does this relate to your next purchase of a Turbocharger?

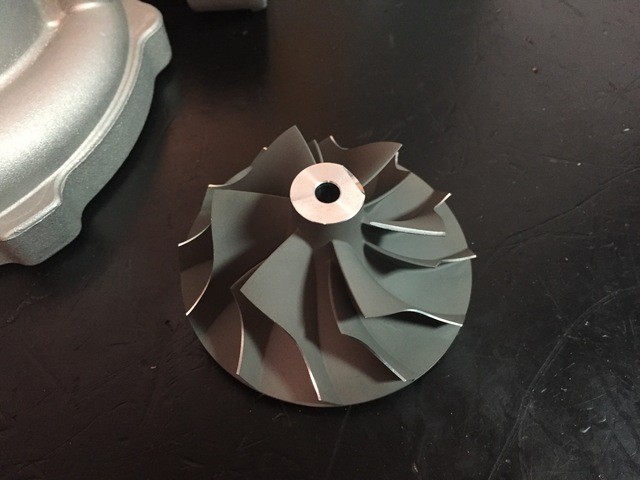

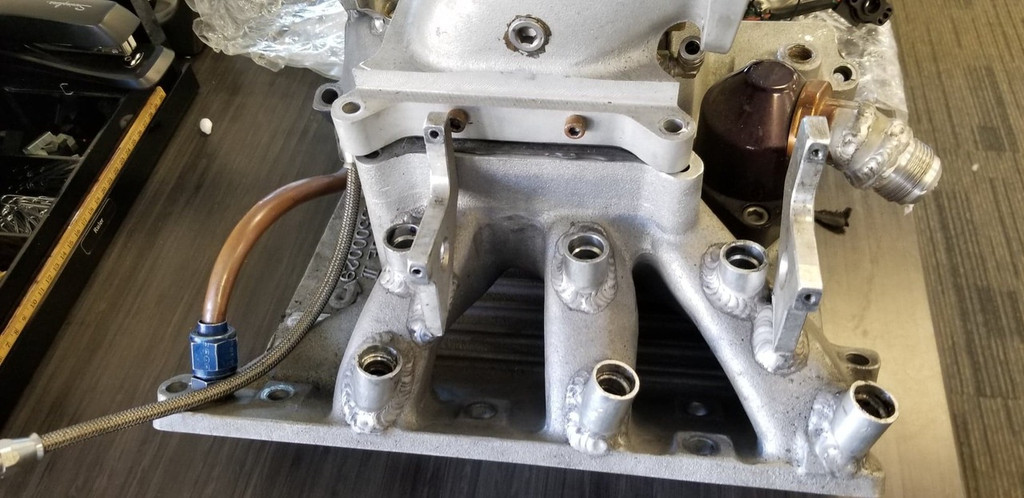

1) A cast wheel is made from aluminum that takes its' shape from the casting used for whatever the product may be. In our case, it is a compressor wheel. Here is a nice picture of a cast wheel from WORK Turbos:

Cast wheels have been used for years with great success. In fact, a lot of billet wheels take their design from cast wheel designs. Billet wheels were only developed because of issues with the lifespan and longevity that some of the cast wheels presented. As the turbo is heat cycled over and over, it can eventually cause failure in some instances. Now we are talking about OEM turbos with hundreds of thousands of miles on them, but nevertheless, manufacturers wanted to find a way to prolong the life of their turbochargers. Hence the billet wheel.

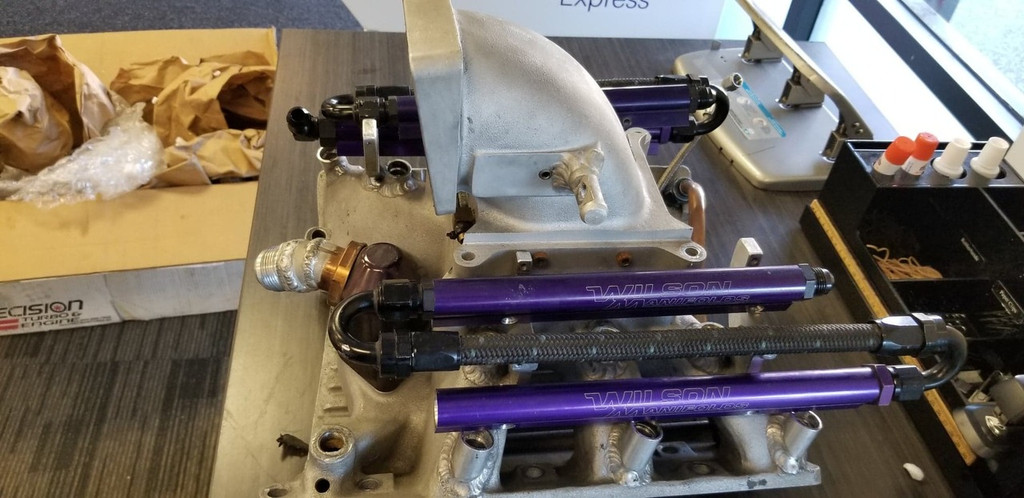

For reference, here are some photos of billet wheels, courtesy of WORK Turbochargers:

Here is a cast wheel next to 2 billet wheels. The cast wheel is the dark grey wheel. It is a 62mm wheel. The 2 billet wheels are sizes; 62mm capable of over 700fwhp, and a 122mm wheel capable of over 3,000hp. Both are designed by Reed Partridge, Owner of WORK Turbochargers. His turbos can be purchased directly from him at

www.workturbochargers.com or

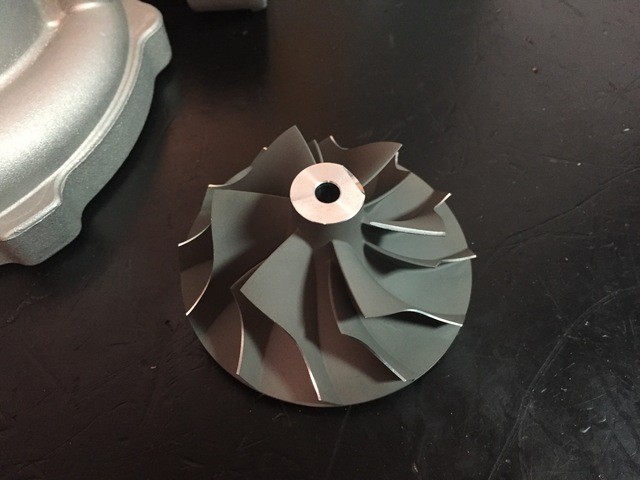

It should be made clear that there is no performance benefit in going from a cast to billet wheel based on just the material alone. The performance gain from going with a billet wheel is related to the difference in base material used for the shape of the wheel and blades. The billet wheel, using a higher grade aluminum than a cast wheel, can withstand more force and pressure compared to a cast wheel, which would allow for more aggressive blade designs and wheel designs. The more aggressive the blade/wheel, the more air it can flow. The stronger the material, the thinner you can make each individual blade, reducing the weight of the wheel overall. This increases spool up, part-throttle responsiveness, and aerodynamics of the wheel. Couple the reduced weight with newer technologies, such as Extended Tip Technology, which I will get into later, and you can see why the billet wheel outperforms the cast wheel.

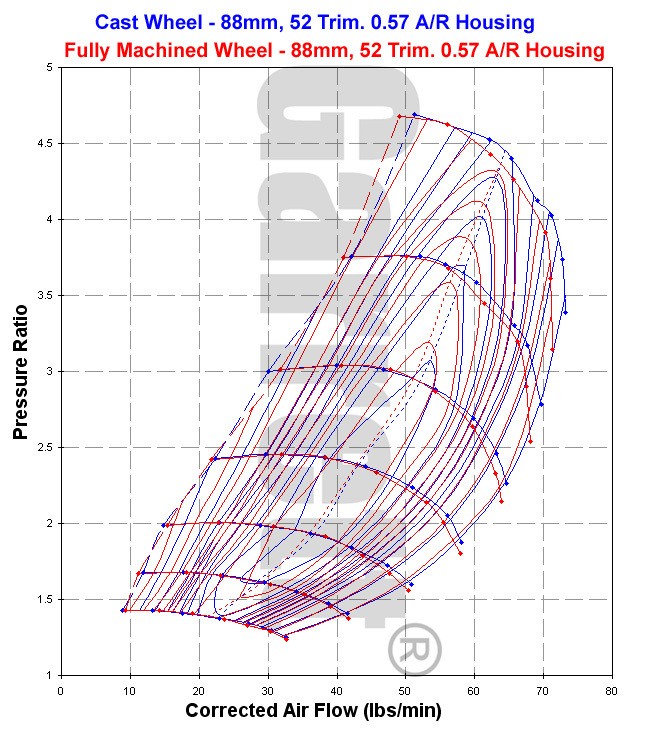

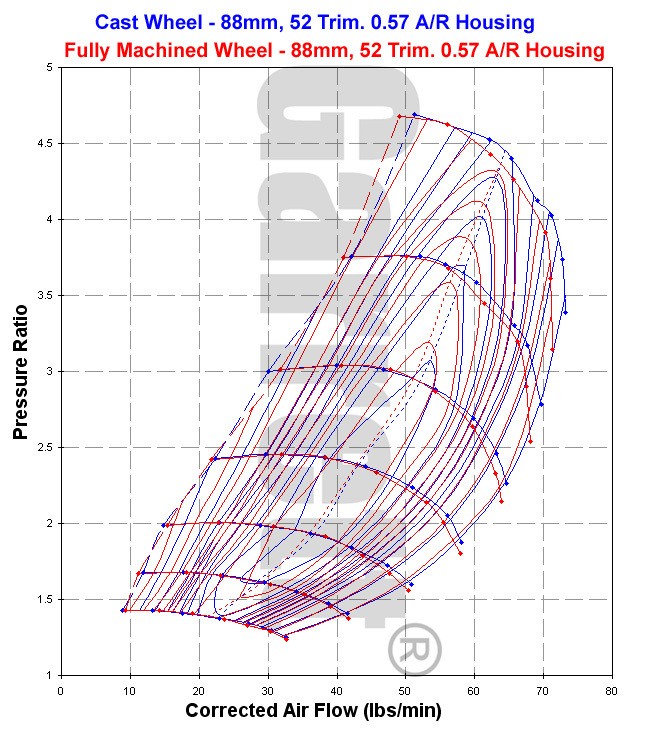

To illustrate just how minimal the difference is between a cast and billet wheel that have the same design, here is a compressor map of the

same wheel made from both cast and billet:

A billet wheel, also know as a Forged-Milled-Wheel (FMW) is made from billet aluminum, typically in the highest performing wheels using 2618 aluminum material, and is made through two different types of milling processes, which I will discuss the differences later on. These two processes are; Flank-Milling, and Point-Milling. Not all billet compressor wheels are made from 2618 aluminum. The difference in the type of aluminum material used for the billet wheel can play a role in the performance of the wheel due to the strength and structural integrity of the material itself, which factors in how aggressive the shape of the blades and design of the wheel can be.

In Summary;

A cast wheel, when properly designed, is still an excellent choice for a turbocharger's compressor wheel. Billet wheels do not offer better performance

based on material alone, it is other factors, albeit related to the material, that allow for the increased performance. Not all billet wheels are made equal. Some use better material than others, and some are manufactured in ways that allow for superior performance when compared with other billet wheels (this is the Flank-milled vs. Point-milled discussion I will get to shortly).

2) If going from a cast to a billet material is not the cause of the increased performance these new billet wheels have, then what is?

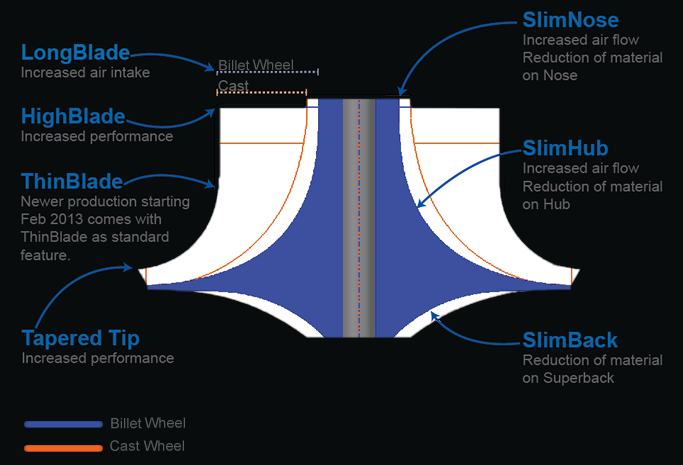

The following is a list of the types of technology and/or design features that are used on today's billet wheels:

A) Extended Tip Technology

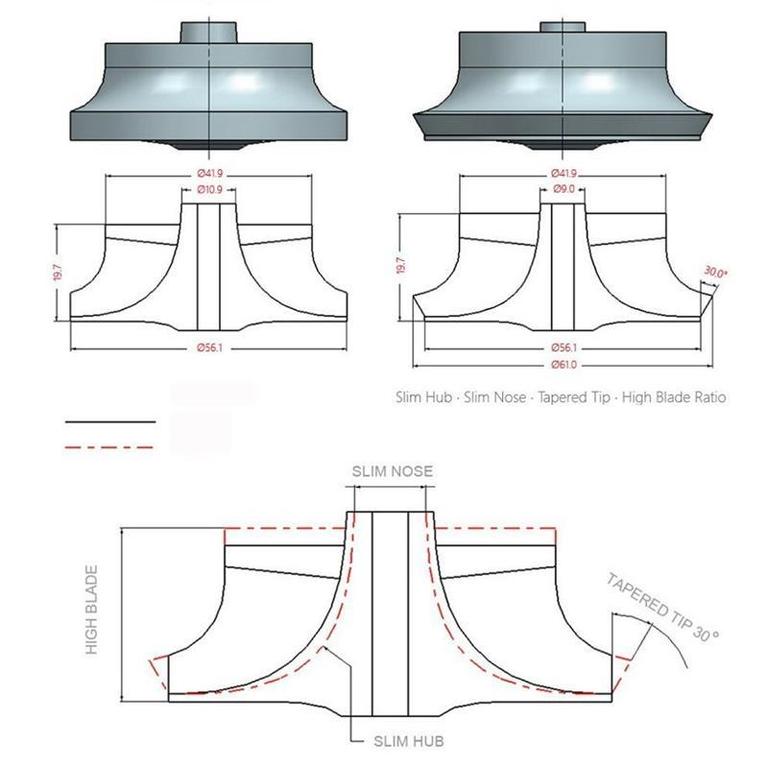

B) Slim Nose Design

C) Slim Hub Design

D) High Pitch Blades

E) High Blade Design

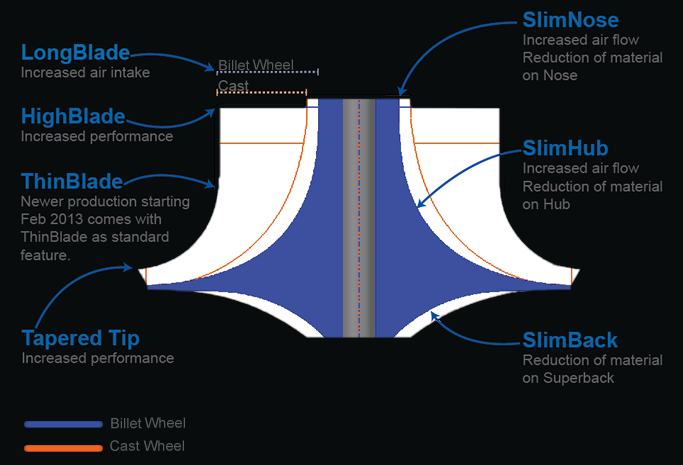

Here is a photo that shows a cutaway of a compressor wheel that may help put a visual on the areas of the compressor wheel this technology is applied to:

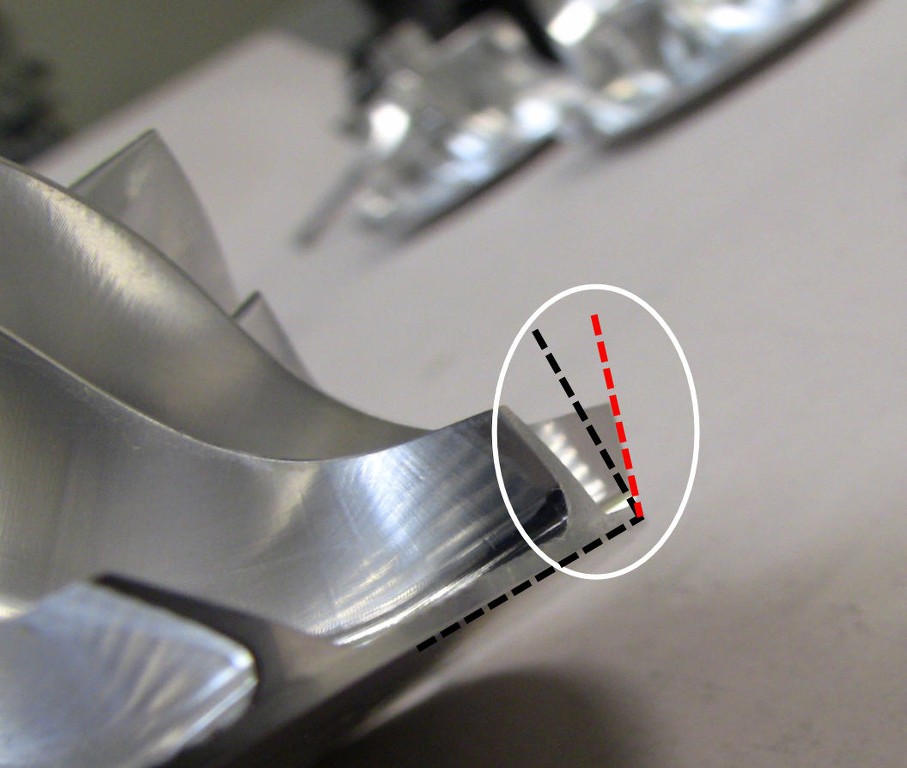

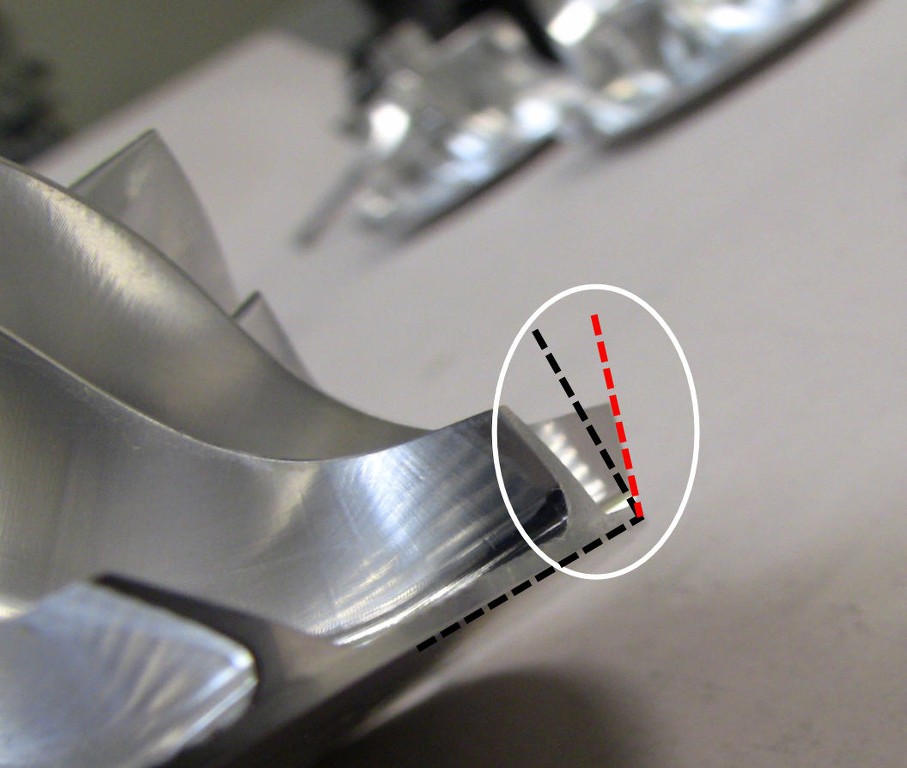

A) Extended Tip Technology= In the photo below the part of the wheel that is located at the dotted red line actually extends past the base width of the wheel (the very bottom of the wheel). Wheels that do not use Extended Tip Technology would normally stop where the black dotted line is. Photo:

This was developed to reduce both the mass and inertia of the wheel, and allow a small wheel to operate similar to a turbo with a much larger inducer compressor wheel. By having a wheel with an overall smaller size, the compressor wheel and by extension, turbocharger rotating assembly, has lower mass and inertia, which aids in spool up and the turbo's responsiveness throughout the rpm range.

Having a compressor wheel that has the blades extend past the width of the base of the wheel allows the wheel to effectively act like a wheel that has a larger sized inducer measurement. In other words, by having the wheel extend past the base of the wheel itself, it can flow more air than a compressor wheel that does not use this technology, because the wheel itself is now wider and can flow more air, which allows it to act like a compressor wheel that is much larger than itself-that does not use this technology. If you had a 62mm wheel that used ETT (Extended Tip Technology) and a 64mm wheel that does not, the 62mm wheel would flow almost the same as the 64mm wheel because the 62mm wheel's ETT makes it act like a compressor wheel of a much larger size, since at the wheel's widest point it is now similar in size to a much larger turbo. The benefits from this are huge; allowing an incredibly high flowing wheel in a much smaller package, with reduced mass and weight compared to larger wheels that do not use ETT, and quicker spooling than wheels of similar output in performance as the ETT wheels are lighter and require less energy to spool up (because they are still a smaller wheel effectively acting like a "bigger" wheel.).

Typical gains from using this technology are around 15% increases in output or more, for a reference in how much this design really influences output.

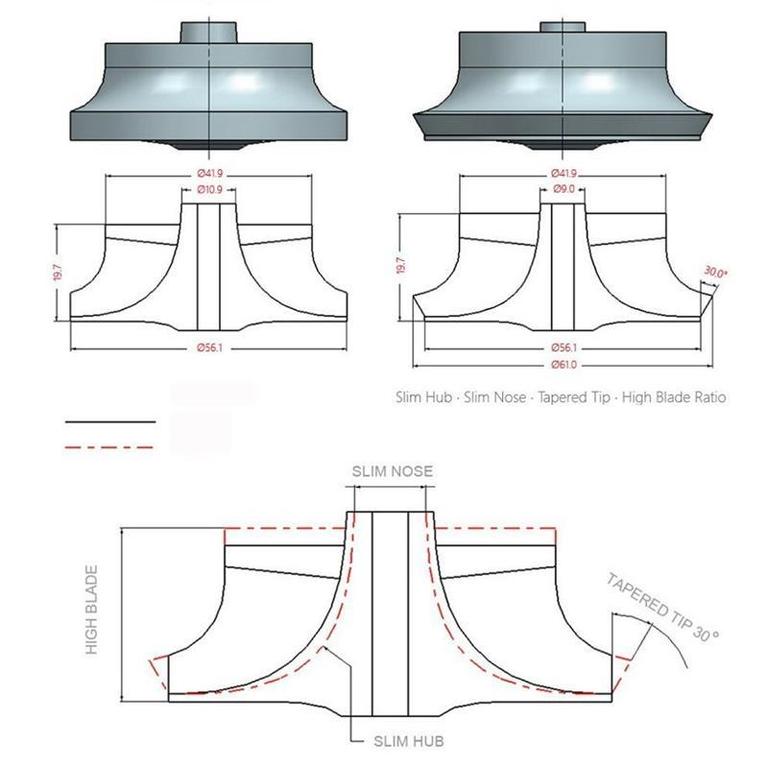

B) Slim Nose Design= The area at the "front" of the wheel, which is the area where the nut is fastened to hold the wheel onto the rotating shaft, is made smaller. It uses a smaller nut coupled with the width of this area being made smaller, which means that the area where there was once a fastening nut is now replaced by the actual compressor wheel. This gives the wheel more surface area and contact surface for airflow. The more area the wheel itself can have on the inlet, the more contact surface for incoming air, which means more flow due to a larger wheel surface, which also means increased spool up because there is more blade surface for air to be in contact with.

C) Slim Hub Design= Reduction of wheel material for less weight and mass.

Here is a photo showing two wheels. 1 wheel (the wheel on the left) has a fatter nose, a wider hub, lower blades, and not as aggressive pitch to the wheel. The wheel on the right (the dotted red line on the drawing below the wheels) shows a slim nose, slim hub, higher blades, and more aggressive blade profile:

D) High Pitch Blades= Blade design is more aggressive and allows for increased aerodynamics and flow capacity.

E) High Blade Design= Compressor wheel blades extend higher than on a cast-material wheel.

I WILL FINISH THIS WRITE-UP LATER ON. RIGHT NOW I HAVE TO GO DRIVE BACK HOME TO CHICO, SO I'LL UPDATE THIS EITHER TOMORROW OR LATER TONIGHT WHEN I GET BACK TO THE HOUSE.