marleyskater420

still needs to learn

- Joined

- Aug 14, 2004

- Messages

- 1,879

So first off, welcome to my build thread (is there a "fourth wall" on the internet?). It has been a journey of 6 years, with a lot of stagnant time in-between.

This first post I am going to discuss the following:

*The goal/history of the car

*The parts on the car/going to be on the car

*People I would like to thank

*How epic the guitar solo in Freebird is

*Anything else I want to, because if you're reading this much, more than likely you'll keep reading, so HA!

The Car:

It is a 1987 Turbo T Limited with T-tops and 2 tone paint. I don't think I could have kids because I wouldn't love them as much as I love this car. All the thanks goes to my Mom, who made this all happen for me. I started this whole ordeal when I was 23. I just turned 30, and this is the closest I've come to getting it completed, and each day it gets closer.

Do you ever remember growing up and seeing race cars or dragsters and saying to yourself "Man, one day I want MY car to be like that!"...well that is what this car is for me. If that kind of car build sounds like something you may totally dig, then keep reading ...

The Build:

Turbo System:

*Gee M Racing 1 3/4" headers for Stage 2 heads, with a 4 bolt Twin Scroll housing, with wastegate provisions plumbed off header sides for dual wastegate operation. EGT bungs will be welded into every primary, along with a pressure transducer bung and O2 sensor bung located just before the mounting flange. I want to send a HUGE Thank you to Juha from Gee M Racing! https://www.facebook.com/GeeMRacingRy/

*Work Turbo 69/73 300SXE, 4-Bolt, Twin Scroll housing -big thanks to Reed and Trae www.workturbochargers.com

*4" MAF pipe

*FMIC will hopefully be a custom Bell Intercooler unit that will support 1600+hp.

*Custom downpipe fabricated by Reed at Work Turbo - BIG Thanks to WORK Turbo!

*Dual Turbosmart Compgate 40's for wastegates -

*Boost control handled via a electronic wastegate solenoid controlled by the MS3 ECM

Fuel System:

*8 gallon fuel cell in trunk

*Weldon 2345A from Justin at Kinsler Fuel Injection www.kinsler.com

*Weldon 14000 fuel pump controller

*-12 feed to pump, -10 to fuel rails to dual -8 inlet at rails. -6 return

*Kinsler 45micron pre-pump fuel filter

*Kinsler 25 micron post-pump fuel filter

*160lb injectors

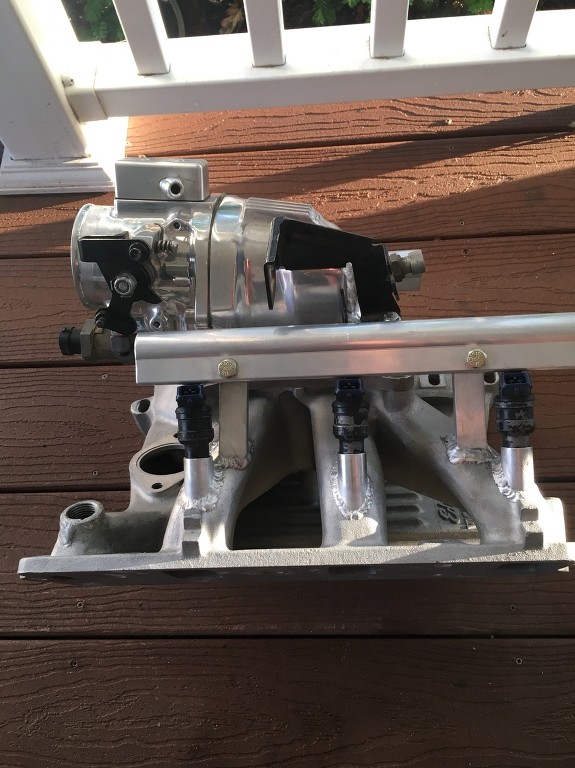

*Custom billet fuel rails for the Stage 2 intake manifold

*WELDON A2040 AFPR - BIG Thanks to Jim Craig at Weldon!! www.weldonracing.com

*Razor's Fuel Pressure transducer for FP monitoring

Engine:

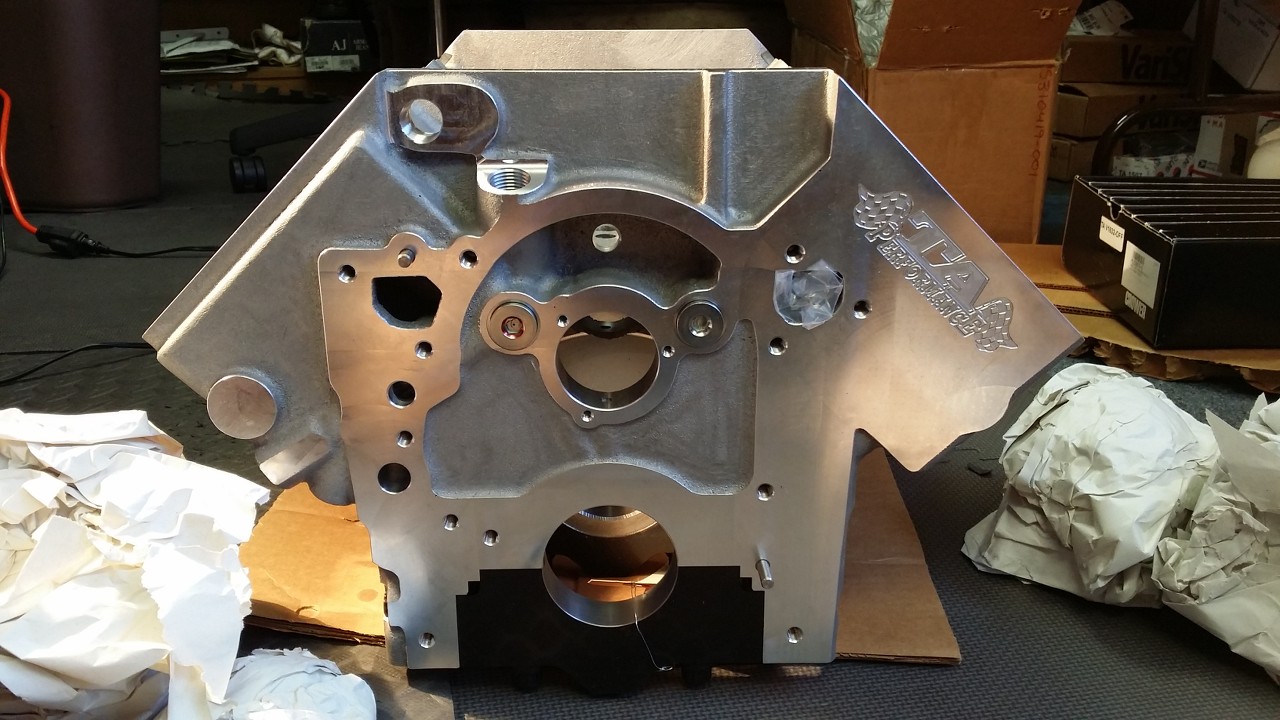

*Kenny Duttweiler built 4.00" Bore TA Block -thank you to Tim at TA Performance

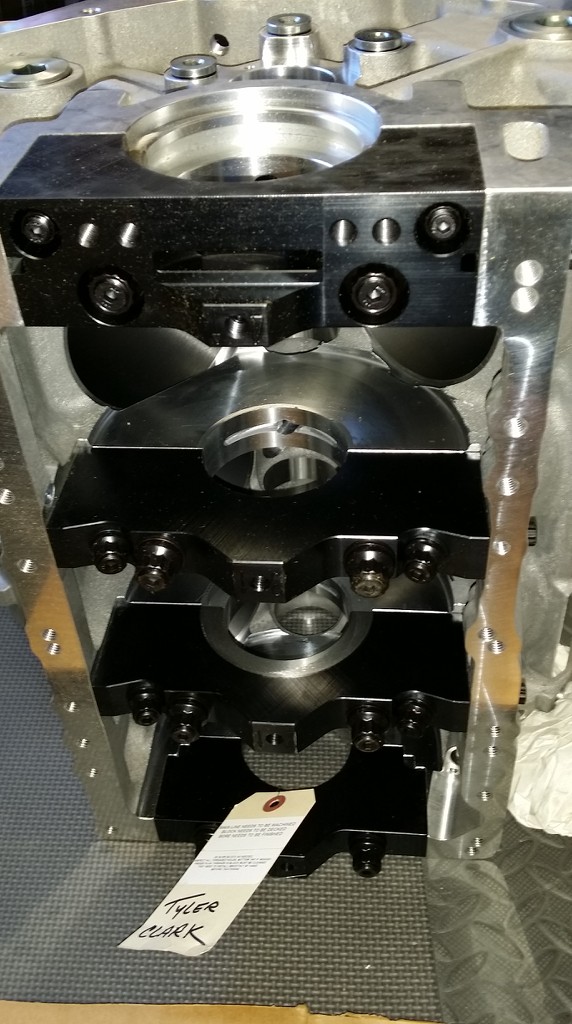

*3.625 billet Crower wide journal crank

*6.3" wide journal Crower billet connecting rods

*Custom pistons as spec'd by Kenny Duttweiler

*Billet cam TBD from Kenny Duttweiler

*Lifters TBD by Kenny Duttweiler

*Stage 2 cylinder heads with Chapman Racing level 3 port work

*Stage 2 carb intake converted to EFI

*72mm billet TB for a EFI-converted Stage 2 carb manifold

*T&D offset roller rockers; 1.64 ratio for intake, 1.58 ratio for exhaust

*AC and Heater box removed

*PS removed and replaced with S10 manual box

*Magic Vodoo Dust

Suspension:

Front:

*SC&C double adjustable upper CA's with Howe extra tall ball joints (Thanks to Mark Savitske)

*SPC lower control arms with Howe extra tall ball joints

*Moroso springs

*Varishock double adjustable shocks

*Hellwig tubular front swaybar

*PST polygraphite super front end kit

Rear:

*Hellwig pro touring adjustable tubular swaybar - Thank you Mark Savitske! www.scandc.com

*Varishock double adjustable shocks

*Replacement johnny joints for rear end housing bushings

*UMI double adjustable LCAs with roto joints

*UMI rear shock tower brace

*UMI weld-in LCA relocation brackets

*Rear UCA relocation bracket and double adjustable arms- thanks to Boost Crew Motorsports!

*QA1 coilover springs

Transmission:

*Janis Transmission 1000hp rated, fully rollerized 200r4 with all the billet parts you can think of

*PTC 9.5 spec'd by Dusty Bradford

Engine Management/Ignition:

**Megasquirt MS3 Ultimate ECM with custom Plug and Play harness by RPS

*LC-1 wideband

*TR-6 ignition

*Eventually a Coil on Plug system with Pantera (IGN-1A) coils

*Custom RPS mounting bracket for CoP system

Things I would like to do one day:

*Built 9" rear end..maybe a Chassisworks Fab 9, or Currie F9, or TRZ 9"

*4L80E

Now for the Thank-Yous, in no particular order..

*My Mom, who is the coolest Mom ever. Period. No questions. She's fucking legit.

*Dean

*Ed

*Mark E

*Jerry

*DonWG

*Danny Todd

*Eric at Turbotweak

*Tim at TA Performance-...Tim has more patience for my crap than just about anyone

*Justin at Kinsler -BUY YOUR FUEL PARTS FROM JUSTIN. DUDE IS LEGIT!

*Trae/Reed at WORK Turbos - BUY YOUR TURBOS FROM THESE DUDES!

*Jeremy P.

*Mr. Jim Craig from Weldon Racing - For making THE best fuel pumps out there!! BUY WELDON!!

*Mike C.

*Ken Mochida- THE Mac Tool MAN!! If you're in CA and need MAC stuff, hit him up!

*Mark Savtiske from SC&C for all my badass suspension parts!

*I'm sure I'll be remembering much more and add them to this list..

*Juha from Gee M Racing!

My Stage 2 Top end with Chapman-ported heads arrived!

Guess what just got finished yesterday...my new Race Headers from Gee M Racing! Check my most recent post in this thread for more info on them!

New Weldon A2040 Adjustable Fuel Pressure Regulator! Thank you Mr.Craig!! www.weldonracing.com :

My WORK Turbo has arrived!! A Borg Warner 300SXE 69/68 with twin scroll, 4-bolt turbine housing and polished compressor cover! Huge Thank you to Reed at WORK Turbochargers!! www.workturbochargers.com :

Nice shot of the twin scroll housing:

The TA block has arrived!!!! :

New Crower crank arrived:

Pics of the new Crower billet rods next to the wide journal L.A. Enterprise Kryptonite billet stroker crank:

Check out the new rear UCA's from Boost Crew Motorsports that allow you to adjust your Instant Center:

My most recent attempt at trying to plumb the fuel lines:

Last edited: