So it has been quite some time since I have updated this thread, and I figured it might be time to take a few minutes to discuss some changes I've made, and talk about a few different topics that I see throughout the forum..

First off, this lovely beauty showed up this week, a Hellwig 1 5/16" tubular front swaybar from SC&C:

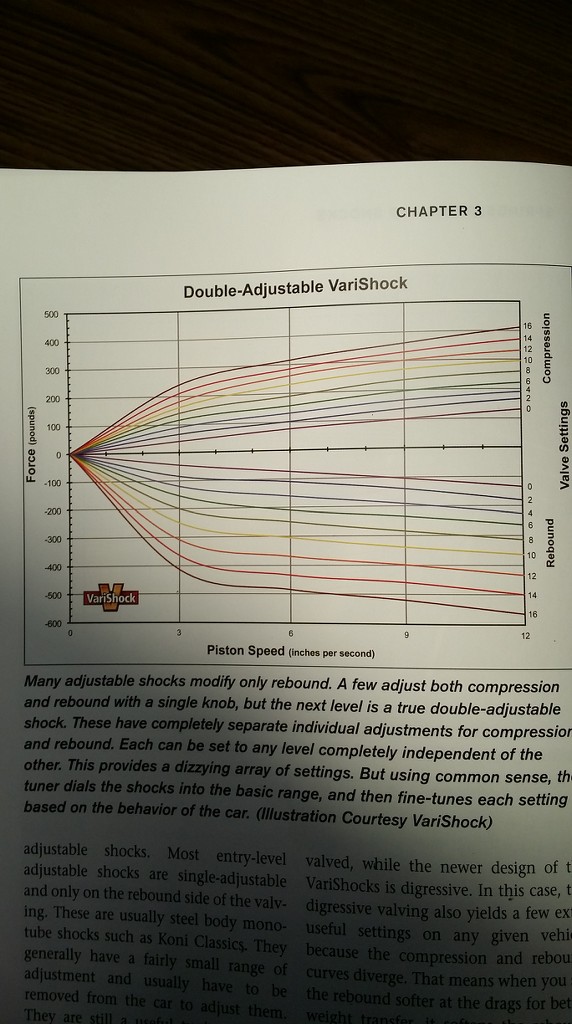

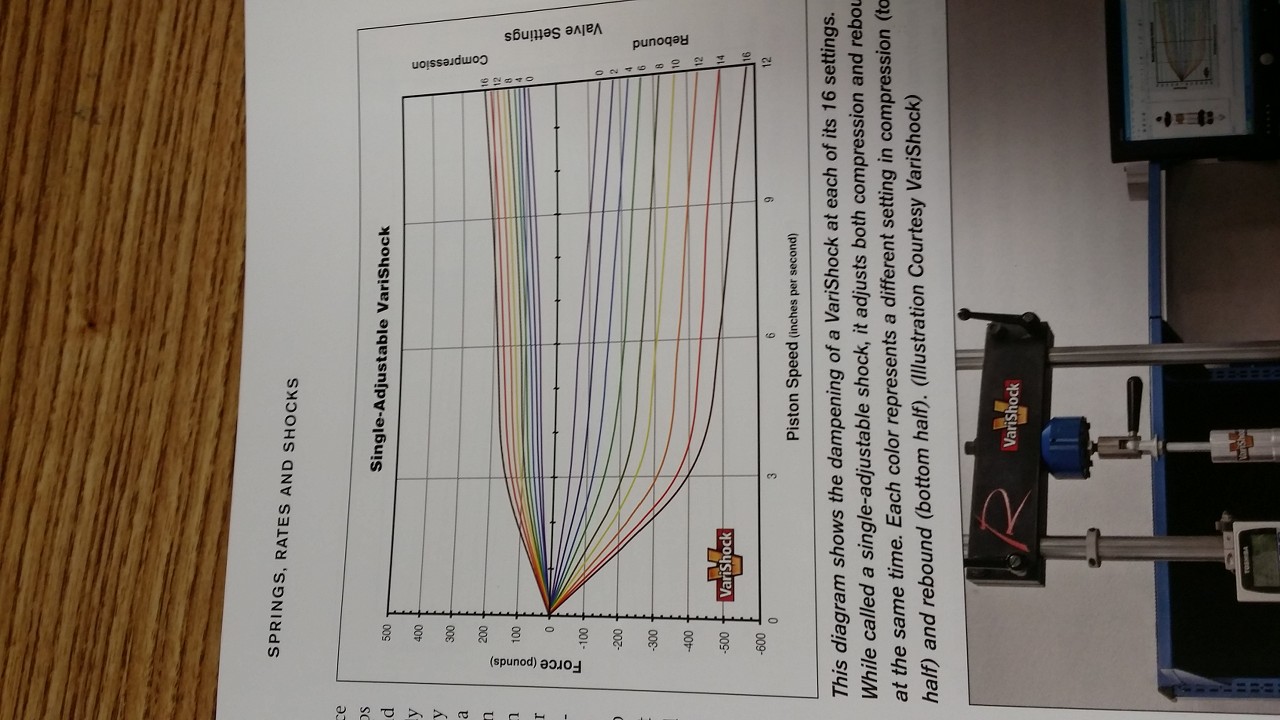

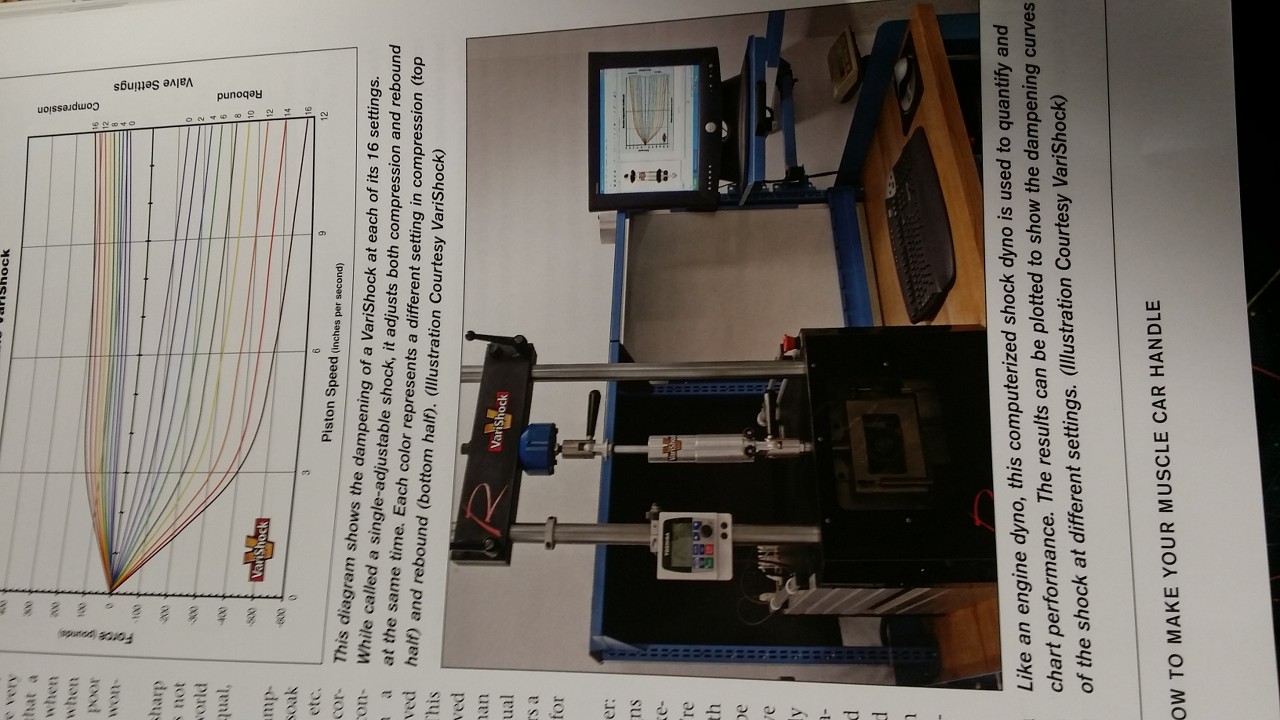

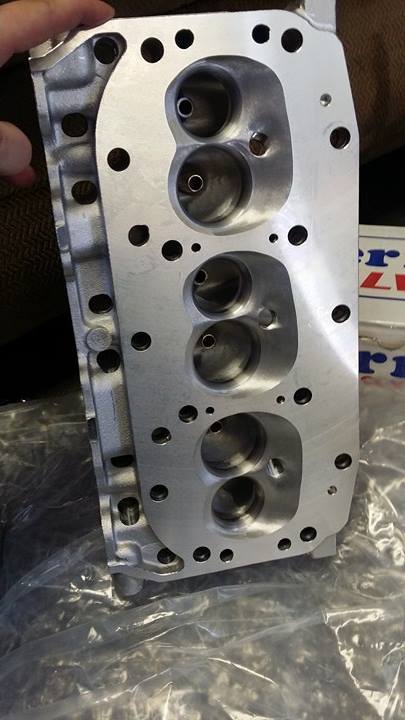

Right now I am waiting for my Varishocks, cylinder heads, fuel rails, intake spacer, and a few other things to arrive.

I just got word the other day that the TA blocks might be ready within a few weeks, which is awesome!

This means as soon as I get my fuel rails and intake spacer, I need to drop them off at the anodizing place!

Now onto a few topics that I have wanted to touch on in the past..

First, I want to talk about the importance of a good fuel filter and how it can affect pressures in your fuel system. For reference, here is a photo comparing a Kinsler Fuel Injection filter (their smallest one) with a nice and expensive Aeromotive filter:

Do you see how much larger the area is that the fuel is filtered through? The larger surface area=more fuel can flow through it, which translates to less of a potential restriction (since the fuel can move more freely and without restriction through a larger surface area compared to a smaller one).

Basic orifice theory, which this information can be had in the actual Kinsler Fuel Injection catalog, page 202 (I encourage everyone to download this catalog as there is more information about fuel flow/everything fuel related, than you could imagine!) states that

"If you want to flow more through an orifice, but keep the pressure the same, then you must use a larger orifice. The flow increases as the

area of the orifice increases."

What does that mean for us? Well, it means that all of you who build these incredible $15+ motors but skimp out when it comes time for the fuel system and fuel filters are shooting yourself in the foot and

potentially causing a restriction in your fuel lines. We know that as fuel pressure increases, fuel pump flow decreases. This is due to basic machining tolerances and other factors, but the point remains that the flow decreases as the pressure increases.

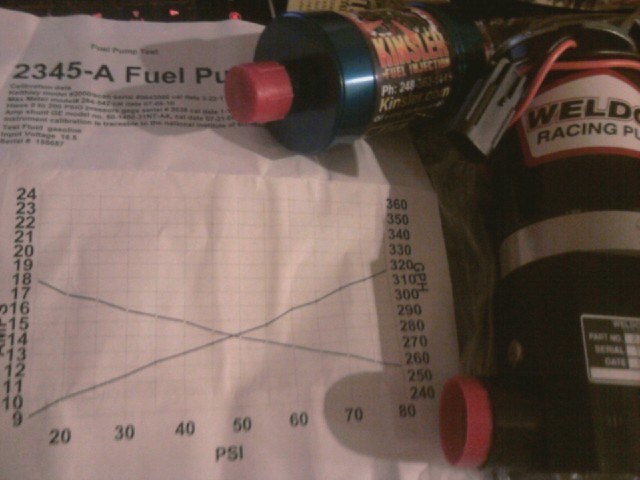

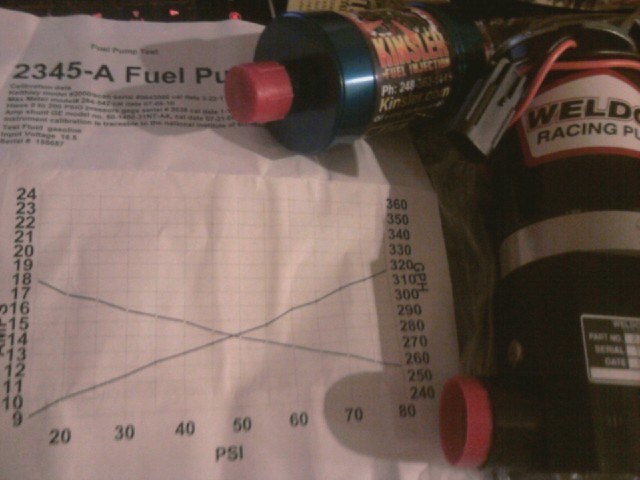

To further illustrate this point, here is a copy of my fuel pump's flow chart. This is a Weldon 2345A pump that I purchased from Kinsler Fuel Injection. Each pump comes flowed, tested, and with a flow sheet like this so you will know

exactly what your pump can flow.

Do you see how at 40psi the fuel flow is about 290GPH, and at 80psi it is 260GPH? This is a drop of about 30gph.

Why should you give a shit about this? Because when you are under boost your fuel pressure increases in a typical 1:1 ratio with the boost pressure, which means your fuel pump is flowing less fuel under boost than at base pressure. If you have a base pressure of 45psi, and you run 25psi, that means your pump sees 70psi (assuming ZERO pressure restrictions). 45psi (base pressure) + 25psi (boost) = 70psi at the pump.

So on my flow sheet my pump at 45psi flows just over 280GPH. If I were to run 25psi of boost, that would put my pump at 70psi (assuming no restrictions), which if we look at my flow sheet my pump flows about 265GPH, which is a 15GPH drop in flow. This matters because when we determine our fuel flow requirements and look at what various fuel pumps flow we may only look at the 45psi flow number, and not the 70-80psi levels.

How does this fuel flow tie in with the fuel filters? Because as I just illustrated, as the fuel pressure increases the fuel flow decreases, so if we have a fuel filter that does not flow enough for what our fuel pump can flow, we may see a pressure increase and thus cause the fuel pump to be at a higher pressure than compared with a fuel filter that has no restrictions.

The main point I am trying to illustrate with all this jibber-jabber, is that when you plan your fuel system and look at what size lines/filter/pump you are going to go with, you want to make sure that your fuel pump can flow more than what your fuel requirements are at your base pressure plus boost pressure. A good rule of thumb is to take your base pressure, add your boost pressure, and add 10psi to that and see if the fuel pump can flow enough at that fuel pressure.

I WILL CONTINUE THIS DISCUSSION IN MY NEXT POST. PLEASE LOOK AT THE NEXT POST FOR THE REST OF MY DISCUSSION. THANK YOU.