Yea, can you explain what the ports in that shroud do?

And thank you for the good thorough answers

So it looks like, if someone were running an old school converter, that they'd have to add a few hundred to those published numbers, seeing as how they were published with the new technology ptc converters then... Good to know sir. thanks.

Absolutely. And it would be a safe assumption about the converter stall numbers as well.

The ported shroud, is an anti surge feature that is machined into the inlet of the compressor cover.

Here's the scenario, at part to half throttle, a decent sized turbo can move a lot of air at say 5-10psi. If the motor can not take this airflow at part to half throttle, the air actually stops and stalls the compressor wheel. This is what is known as surge. The wheel starts a chirping or

chiii chiii chiii sound.

Like that huh.

This is the rotating assembly starting and stopping, starting and stopping very abruptly. Which can be very bad on bearings and seals with the tremendous loads incurred on the internals. If you can visualize, a turbos normal operating range, as far as rpms are converned, could be anywhere from 100-120,000 rpm. Depending on model and application. So, the turbo is spooling up, 3k, 4k, 10k, and then suddenly BAM! Stall/Surge. Not a good situation for either style of rotating assembly. Eventhough, the dual ball bearing versions were designed to better handle these tremendous loads.

Ok, back on track, the ported shroud allows the excess airflow that the motor cannot take in, a place to escape. The extra unused air actually recirculates through a slit machined inside the inlet of the compressor cover. Air travels through this slit and exits out of slots or bullet holes that are machined into the compressor cover. Back into the inlet air stream. Effectively keeping the incoming air, flowing in one direction.

Here is a picture from Garrett's site that helps better illustrate it.

You can sometimes hear turbos surging at the starting line as the driver tries to hold the boost at a certain level with his foot when staging.

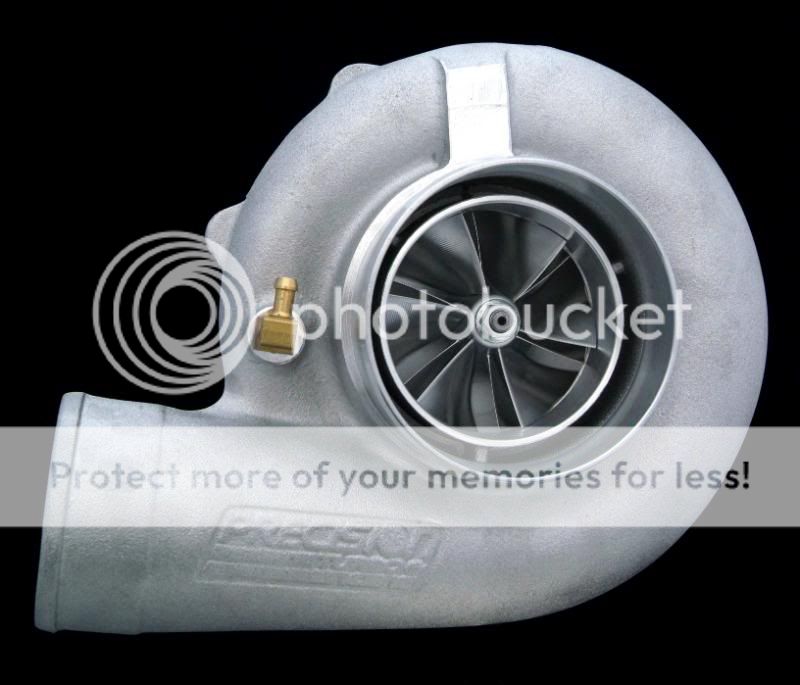

In my opinion, on a street driven car that will see a lot of part or half throttle driving, with a turbo that is a 67mm or larger, it is actually beneficial to run a Ported Shroud compressor cover. Here's a couple more pictures that show Precision's two types of ported shrouds.

1st style.

This is a Billet 76 turbo with the milled slotted version of our ported shroud. This style is typical of all the ported shrouds on the larger series turbos. Typically 70mm and larger compressor wheels.

2nd style.

This one, is a Billet 6262SP turbo with the bullet hole style ported shroud S cover. If you look closely, you can see the ported shroud slit, where air can escape back through the bullet holes.

The tone that a ported shroud compressor cover equipped turbo makes, is very pronounced, compared to a straight inlet cover. If you can imagine the sounds of a 767 airliner spooling up for take off, that's what they sound like.

Anywho, to recap, it helps to eliminate surging under non WOT conditions.

Hope this helps better explain it.

Patrick

P.S.

JC3569 and

hensleyt.

Let us know more about both of your goals ET/MPH wise, and we can better help suggest a turbo that would suite your combo.