Timing cover/gerotor oil pump project

- Thread starter steveX

- Start date

Welcome!

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

turbofish38

Le Pétomane

- Joined

- Dec 3, 2002

- Messages

- 6,160

I can tell you the 86-88 NA 3800 doesn't bolt onto a 109 style block.And neither do the Series I and II covers.

bmackinnon

Active Member

- Joined

- Feb 24, 2005

- Messages

- 2,092

The georotor thing has been done... check this link out.... among the other super-cool things dude has done.... dual-fuel system, quick start setup, turbo fwd wagon, super impressive stuff...

78 Malibu Touring Coupe

Enjoy...

78 Malibu Touring Coupe

Enjoy...

I`ve been looking at the buick 3.8 and 3800 timing cover bolt pattern and it looks the same to me. was wondering if anybody try bolting a 3800 timing cover to the 3.8 (109) block?.

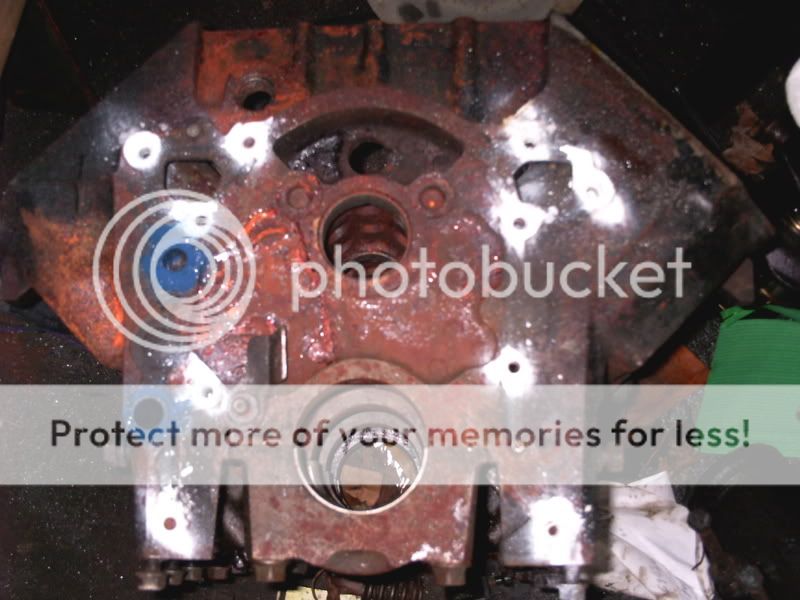

Here is what am looking at:

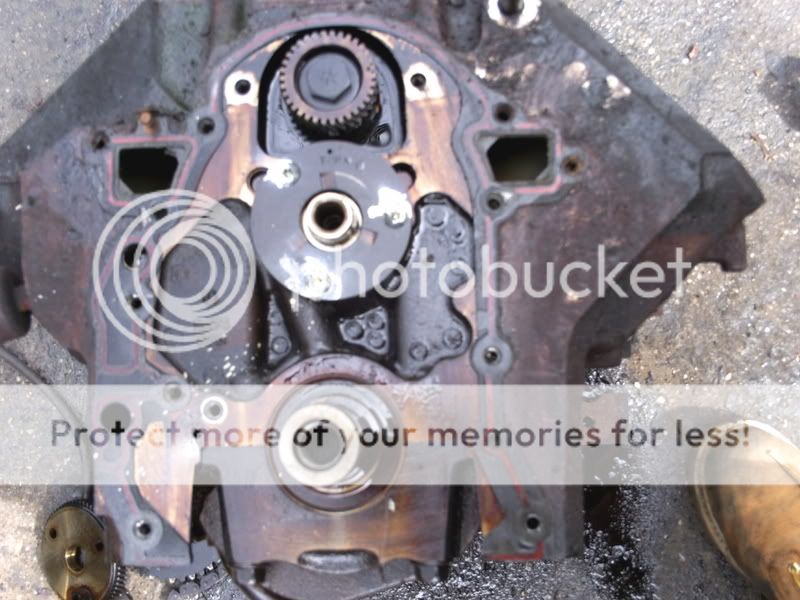

here is the snout.

If you take a look at the two, you'll notice the 3800 has the extra balance shaft above the cam shaft. The top half of the housing's different. The bottom halves are similar, which is why the guys that have takled this issue use the top half from a 3.8, and weld the bottom half of a 3800 to it.

If the 3800 front cover is the same up to the coolant ports, I wonder if you could just cut off the top of the 3800 cover and weld in a piece to mate to the 3.8L block. Or mill the back of the top part of the cover and weld in a plate to the back of it to create a lower area for the gasket to mate with the block?

David

David

Ok, I'm finally home so I can get in on this one. I am one of the 4 that has done this and the only one that I know of to use the Series II front cover. They are not the same up to the cooling stuff. infact the oil transfer hole from the cover to the block is relocated. You also have to run an Edelbrock timing chain and shave the oil pump backing plate 0.020in to clear the timing chain, a Rollmaster doesn't fit. I know I've tried it. Also 1 of the bolt bosses is relocated on the L67 cover and while I didn't see anything to stop me from drilling and tapping it out I refrained since I didn't have an ultrasonic tester to see how much metal was there. Another thing is that the block isn't wide enough on the front to cover the oil bypass return passage from the bypass to the oil feed hole so you'd have a huge leak if you didn't have it welded and machined closed. The final concern is that if you use a Edelbrock chain, a cut down L67 gear as the oil pump drive, and keep the stock balancer in place you will run into problems with having to cut down the back of the balancer potentially excessively. My solution was to run a later L67 crank sensor and "quickstart" rings on the back of the balancer and that pushes the balancer out farther so you have more balancer snout and run an RJC "short" pulley designed for an MSD crank trigger.

To fit it on the block I chopped an L67 cover in half right above the cast rib in the cover then chopped a Stage II drysump upper cover in half with about 1/2in overlap. I think hand fitted the drysump section over the L67 section by making my own aluminum spacer plate and getting it 98% there in metal and the last bit with Quik-Steel reinforced epoxy and JB-Weld as a skim coat filler. I solved the oil supply hole problem by machining out the oil pressure hole on the block for a 3/8in NPT fitting and threading an adapter in it and run the oil in that way. I've not run the engine yet so I can't say how well it works but I have to say that if I was to try this again... I'd start with a Rover "Intermediate" cover with a gerotor and distributor shaft and see if that was easier to make work since a Rover V8 is nothing more than a Buick 215 that was the basis for the 300/340 SBB that the V6 is based off of with some 350 based improvements.

See the following pictures for what I've done and some of the stuff I encountered.

To fit it on the block I chopped an L67 cover in half right above the cast rib in the cover then chopped a Stage II drysump upper cover in half with about 1/2in overlap. I think hand fitted the drysump section over the L67 section by making my own aluminum spacer plate and getting it 98% there in metal and the last bit with Quik-Steel reinforced epoxy and JB-Weld as a skim coat filler. I solved the oil supply hole problem by machining out the oil pressure hole on the block for a 3/8in NPT fitting and threading an adapter in it and run the oil in that way. I've not run the engine yet so I can't say how well it works but I have to say that if I was to try this again... I'd start with a Rover "Intermediate" cover with a gerotor and distributor shaft and see if that was easier to make work since a Rover V8 is nothing more than a Buick 215 that was the basis for the 300/340 SBB that the V6 is based off of with some 350 based improvements.

See the following pictures for what I've done and some of the stuff I encountered.

Attachments

turbofish38

Le Pétomane

- Joined

- Dec 3, 2002

- Messages

- 6,160

94-99 Rover V8 engines, check the salvage yards. Cost, probably in the $50-75 range.

I'd give my left nut to find a Rover V-8 in the boneyard let alone a part for one. Oh I meant a self service yard. I doubt a full service yard would sell just the cover unless they knew the short block was FUBAR.

Okay I have to ask a stupid question. What is the advantage of the gerotor pump on our engines? Seems like a lot of work.

well

I know that knock will kill a gerotor oil pump due to the harmonics . The 4.6/5.4 ford guys and the honda guys have been having a problem with this i dunno if the buick will or not.

I don't really see the big adavanges over the stock set-up. The stock oil pump witht he correct mods done to it and the bearing clearances will have great oil pressure. the only thing that will change is the load of the cam sensor and timing chain.

besure to cheack out turbo1dr's page as he has had some changes over the yrs to his front pump covers and gear drives. this didn't happen overnight either.

78 Malibu Touring Coupe

I know that knock will kill a gerotor oil pump due to the harmonics . The 4.6/5.4 ford guys and the honda guys have been having a problem with this i dunno if the buick will or not.

I don't really see the big adavanges over the stock set-up. The stock oil pump witht he correct mods done to it and the bearing clearances will have great oil pressure. the only thing that will change is the load of the cam sensor and timing chain.

besure to cheack out turbo1dr's page as he has had some changes over the yrs to his front pump covers and gear drives. this didn't happen overnight either.

78 Malibu Touring Coupe

turbofabricator

Well-Known Member

- Joined

- Mar 7, 2004

- Messages

- 4,261

How about just installing a Peterson external oil pump. Belt driven off the crank and no mods needed to the timing cover. They are affordable, too. I DO like to see innovations and modifications to stock factory stuff, though. (Just look at my modified factory parts car ) The stock oil pump works fine. Are they the most efficient?.........No way. But, they do work just fine (even in completely stock configuration) in a 9 second car. Most engine failures are NOT caused by oiling issues. If you want to do it right, step up to a dry sump. That is worth approx. 40 horsepower, but at a cost of $4,000+ for all the needed pump, tank, filter(s), hoses, fittings, brackets.................it is hardly worth the effort unless you race the car at a 1,000+ hp level.

) The stock oil pump works fine. Are they the most efficient?.........No way. But, they do work just fine (even in completely stock configuration) in a 9 second car. Most engine failures are NOT caused by oiling issues. If you want to do it right, step up to a dry sump. That is worth approx. 40 horsepower, but at a cost of $4,000+ for all the needed pump, tank, filter(s), hoses, fittings, brackets.................it is hardly worth the effort unless you race the car at a 1,000+ hp level.

The Intermediate Rover cover is off of the GEMS engines(1996-1999, BAE era), not the later Thor Motronic (1999-2002, the BMW era). The earlier covers still had spur gear pumps and the later covers didn't have distributor holes however it is theortically possible to use an Series II cam sensor and flying magnet setup since the LC2 setup is a metal shield interupter hall effect sync switch and the Series II is a flying magnet hall effect sync switch.

The 215 (3.5, 3.9, 4.2, 4.0, 4.6 Liter Rover dirivatives) are not Nailheads but the first generation Buick Small Block. The original Buick V6 was based off of this designed and as the SBB evolved the V6 adapted along with it to share production parts. The 215 looked like a Nailhead to tie into the larger Buick engines of the time with thier characteristic valve covers but the distributor was in the front not the back like a Nailhead.

I started doing this as an engineering exercise off of Kendall's experiments with this on his Stage II "Second Hand Six" I thought the gerotor design with its divorced oil pump drive releived the strain on the front cam bearing and is a more efficient pump that holds its clearances better. They have been used for years on pretty much all GM transmissions and Mo'Par engines. Lately they have started making billet gerotor units for the SBC and BBC to deal with needs of the supersized stroker motors and tall deck blocks. This however became a nessecity when I discovered that the V6 will sit so far back in the engine bay of my '64 Riviera that the stock spur gear oil pump setup would conflict with the engine cross member and since I was already on this path and didn't want to notch my frame I decided to fully commit to this project.

Expect results in July, I am also retrofitting an L67 supercharged ECM and harness to run the engine using OBDII controls and a flash based tuner.

The 215 (3.5, 3.9, 4.2, 4.0, 4.6 Liter Rover dirivatives) are not Nailheads but the first generation Buick Small Block. The original Buick V6 was based off of this designed and as the SBB evolved the V6 adapted along with it to share production parts. The 215 looked like a Nailhead to tie into the larger Buick engines of the time with thier characteristic valve covers but the distributor was in the front not the back like a Nailhead.

I started doing this as an engineering exercise off of Kendall's experiments with this on his Stage II "Second Hand Six" I thought the gerotor design with its divorced oil pump drive releived the strain on the front cam bearing and is a more efficient pump that holds its clearances better. They have been used for years on pretty much all GM transmissions and Mo'Par engines. Lately they have started making billet gerotor units for the SBC and BBC to deal with needs of the supersized stroker motors and tall deck blocks. This however became a nessecity when I discovered that the V6 will sit so far back in the engine bay of my '64 Riviera that the stock spur gear oil pump setup would conflict with the engine cross member and since I was already on this path and didn't want to notch my frame I decided to fully commit to this project.

Expect results in July, I am also retrofitting an L67 supercharged ECM and harness to run the engine using OBDII controls and a flash based tuner.

Turbo1dr

9 Sec Wanna-Be

- Joined

- May 25, 2001

- Messages

- 2,441

I can tell you the 86-88 NA 3800 doesn't bolt onto a 109 style block.And neither do the Series I and II covers.

That is not true. The Series I FWD engine cover bolt holes are a perfect match to a 109 engine. On my gerotor front cover I made, I use a stock FWD timing cover gasket without any modifications. I didn't have to drill and tap any other holes in the block or cover to make it work properly. Using a Series II cover (like CTX-SLPR) the bolt holes do not match.

This gasket was not laying flat against the engine....

Older picture...

Similar threads

2

2K

16

4K

Online statistics

- Members online

- 19

- Guests online

- 3,652

- Total visitors

- 3,671

Totals may include hidden visitors.