Mike T

Well-Known Member

- Joined

- May 3, 2013

- Messages

- 1,598

Just throwing this out there. I have noticed a lot of guys are going for the higher compression builds ..... I'm curious as to the real advantages to this over just turning the boost up?

By registering with us, you'll be able to discuss, share and private message with other members of our community.

SignUp Now!I like the higher compression builds.my current combo has gone faster with more compression and the car feels more responsive.remember what drives the turboI have noticed a lot of guys are going for the higher compression builds ..... I'm curious as to the real advantages to this over just turning the boost up?

There's no such thing as "will make up for". Once you lost ground going to lower compression there is nothing you can do to get it back. More boost means more back pressure and will hit a wall with VE sooner than a higher compression engine would.Since my motor is going to be on the lower CR side.... hopefully running a lot of boost in conjunction with the extensive port work that I've done to the heads will make up for any short comings of the lower CR.

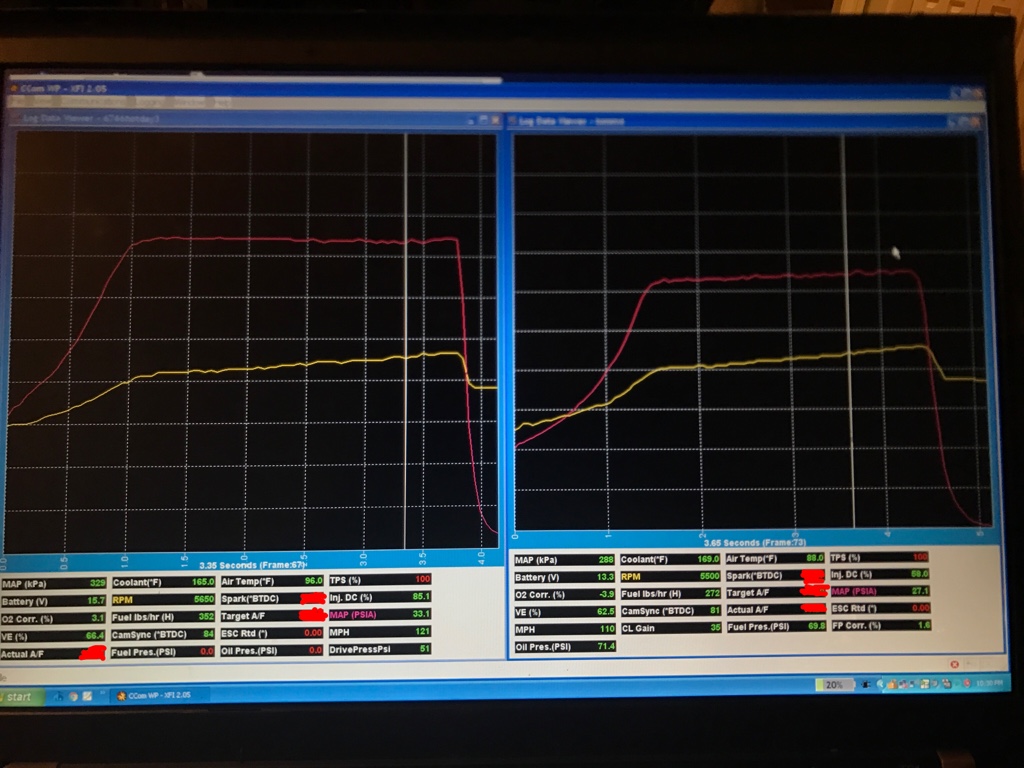

There's no such thing as "will make up for". Once you lost ground going to lower compression there is nothing you can do to get it back. More boost means more back pressure and will hit a wall with VE sooner than a higher compression engine would.

AG.

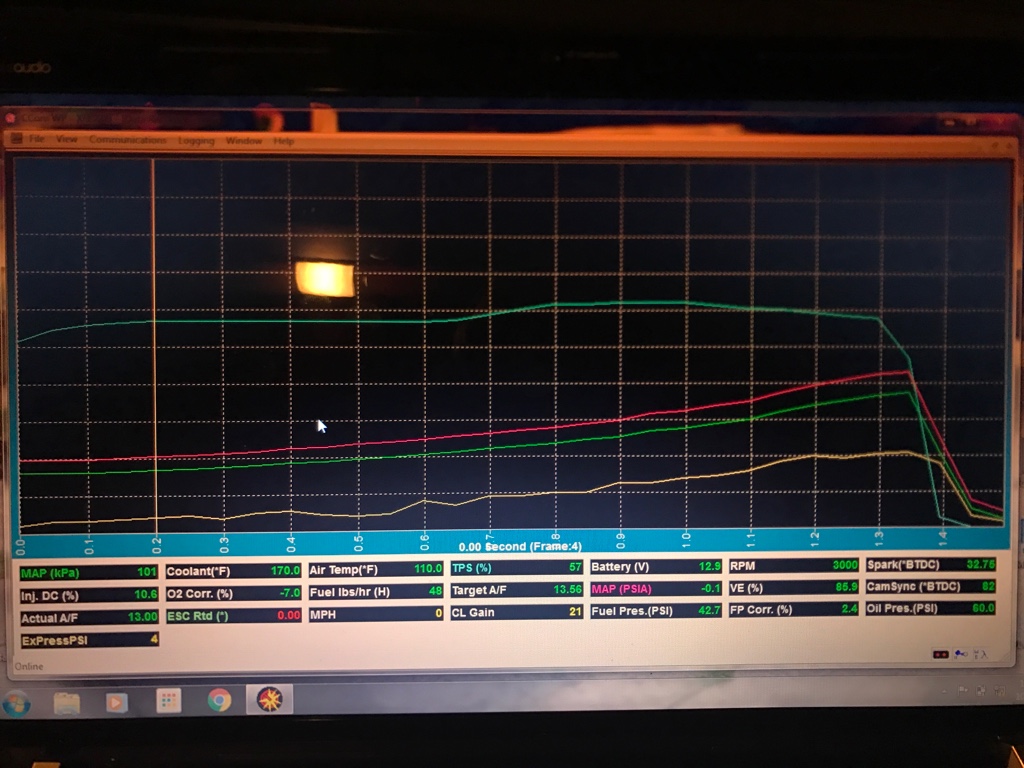

You shouldn't be using only manifold pressure as your reference point for how efficient an engine is. I will say that engines that make the power at lower manifold pressures with no other changes will typically go noticeably faster because the turbo has less work to do to move the air. You may go backward in power trying to make 35psi. Exhaust pressure in the 80's and cylinder fill in the crapper. When the exhaust pressure vs manifold pressure starts getting ugly the power (VE) falls off a cliff. So to get that engine more efficient only mechanical aspects of it can improve it. You're al out of manifold pressures positive effect to fill the cylinder. So raise the CR, reduce valve overlap, taller gearing, converter very specific, or leave everything the way it was and go with more turbo, specifically the hot side since it seems to be the biggest bottleneck on most engines. If I were to go all in on the turbo I have little doubt that on the 9.45:1 engine it would make much more than my 8.3:1 and it would run the turbo out at lower manifold pressures.I understand that one combo may be more efficient than another. It may take 35 PSI for my motor to make 750 HP where as another higher compression motor may make the same HP at a much lower boost level.

that's if you can make that kind of boost.on a good motor it can be real hard to make big boost the turbo has to have enough nut.It may take 35 PSI for my motor to make 750 HP where as another higher compression motor may make the same HP at a much lower boost level.

Plenty of expertise here.

In my simple mind:

Work (Trq) is achieved through pressure (force) and leverage (stroke). The key is to control pressures and associated heat energy of combustion.

HP is a calculated number of RPM and Trq. Great thread.

There is another GREAT thread somewhere about 8 years old now called "boost vs back pressure". Should be a sticky imo.