Nothing to exciting tonight. I cut out and smoothed the EGR tower in the lower intake, and cut the rolled lips on the uppipe. After some researching, I'm going to take the chance and run the uppipe with out the beads. I'll use the hair spray trick to keep the hoses in place, and I already run nice T bolt clamps. If it starts blowing off often, I'll buy another and leave the beads.

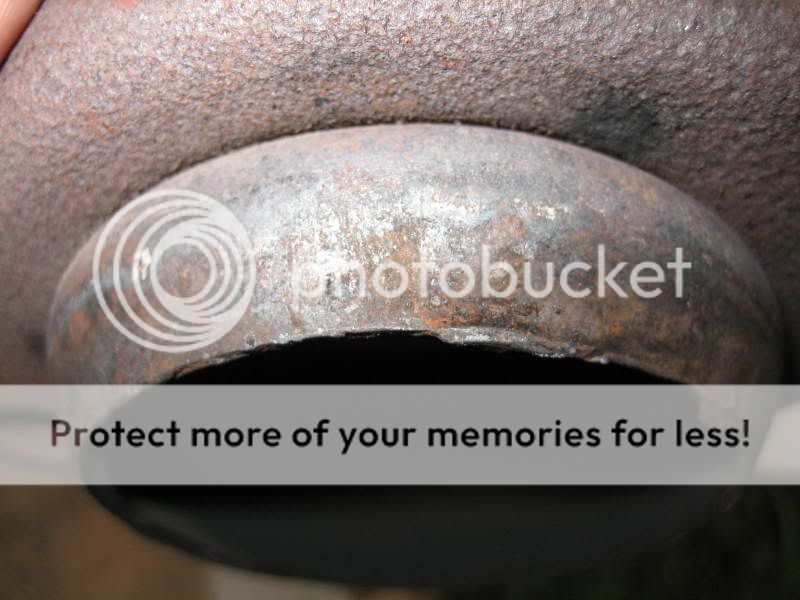

Here is a shot of the lower intake with the EGR tower.

And here is how it looks with it cut out. I used my cut off wheel on my air grinder and on the dremel to get most of the tower off. Then I used the carbide bits to get it smoothed down. It took alot more work then I thought, but I think it came out okay. I'm going to take it to my welding guy tomorrow to have the EGR opening welded shut.

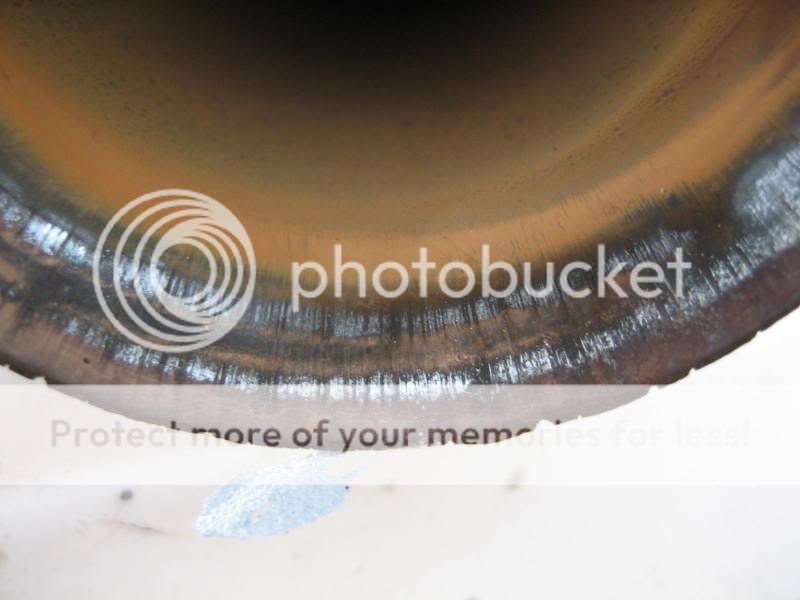

Here are two shots of the up pipe with the beads removed. I'll sand it down real good and bellmouth both sides.

I picked up a set of telescoping gauges. This will help me understand the pinch points in the lower intake.

I do have one question. I noticed on the exhaust manifolds, they use a ball/socked type of seal, instead of a gasket. The ball part is on the the manifolds, and about 3/8" of it is used to seal against the crossover sockets. Does anyone know if I can port those about half way down and still keep a seal? They currently seal real nice, but they do look like they would hinder flow, yet I don't want them to leak.