DougsfastZ

4.1

- Joined

- Jan 30, 2004

- Messages

- 727

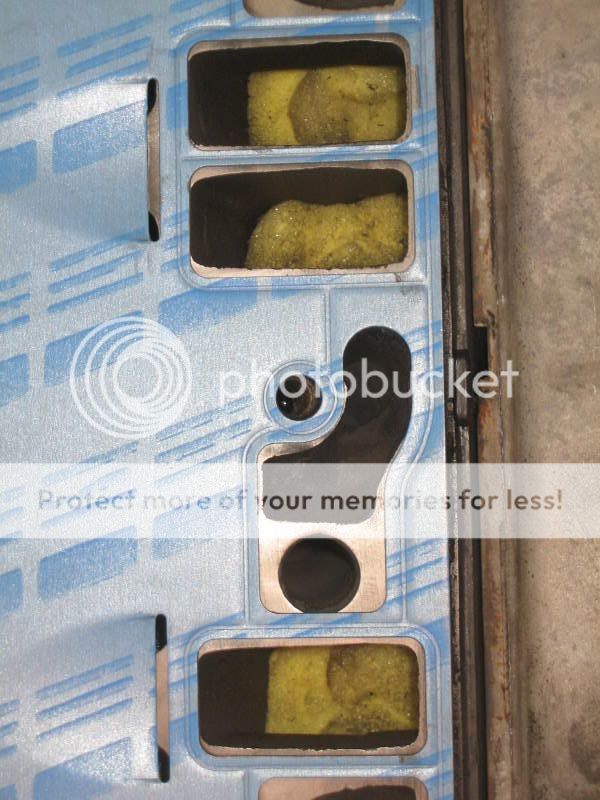

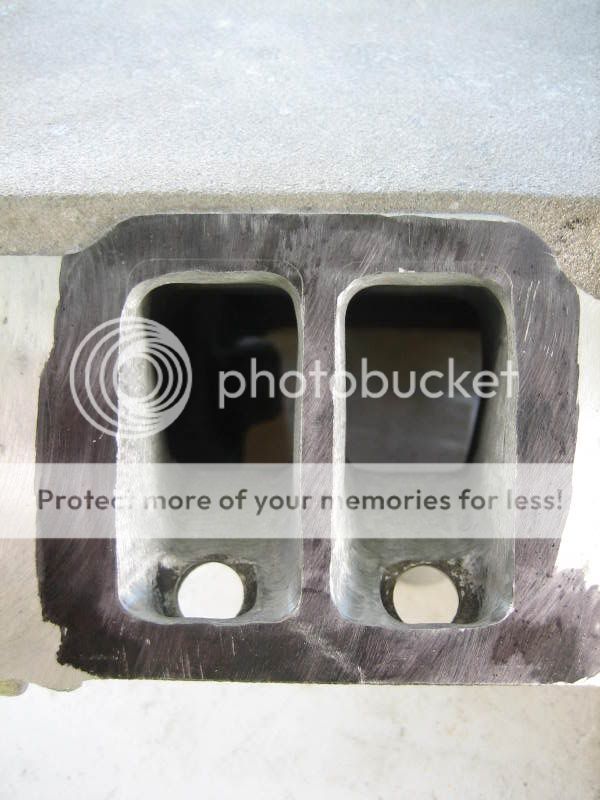

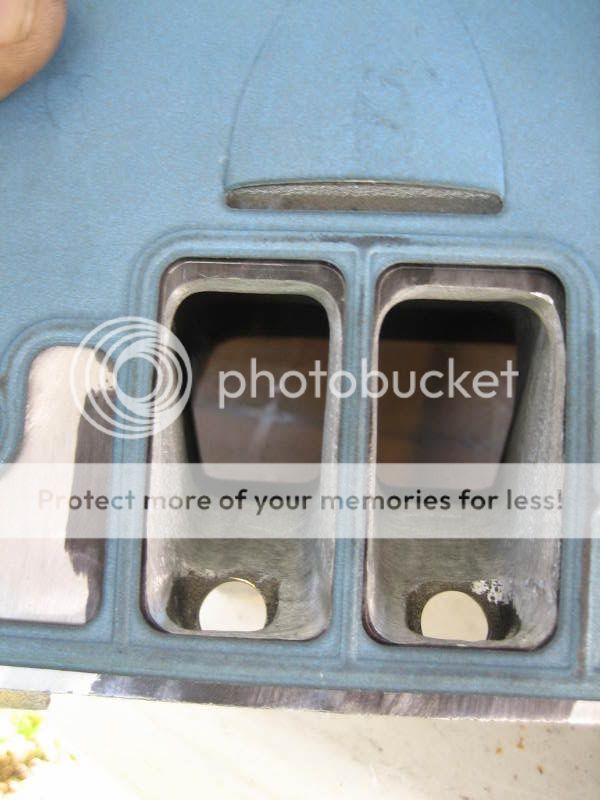

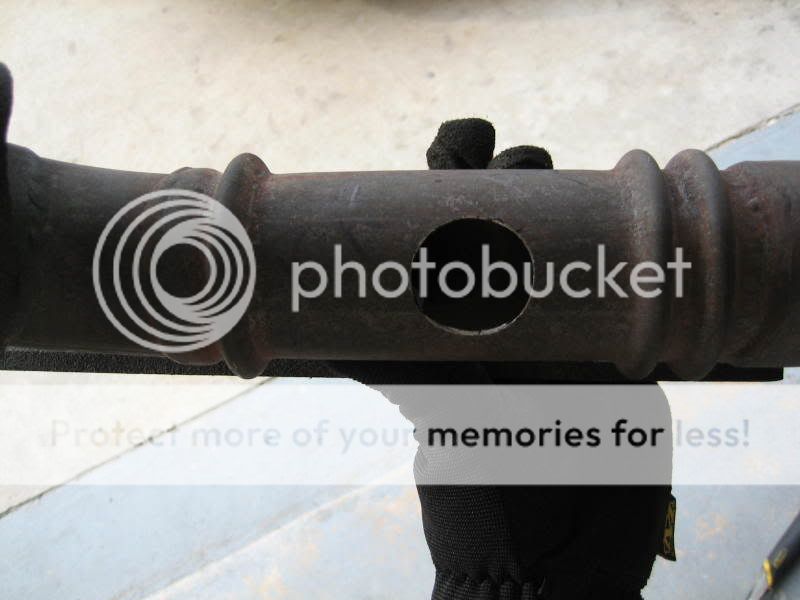

After learning from forcefed3.8's about the over hang in the exhaust manifolds with the primaries meeting the log, I decided to drill some holes and port them. I only had to drill three holes, one to port cylinder #5, one to port cylinder #4 and one to port cylinder #2. I was able to port the primary outlet on cylinder #6 through the inlet of the manifold from the crossover. I didn't need to port #1 or #3. I used an 1 1/4" bi metal hole saw to drill out the access holes. I kept the material that was removed to have them welded back.

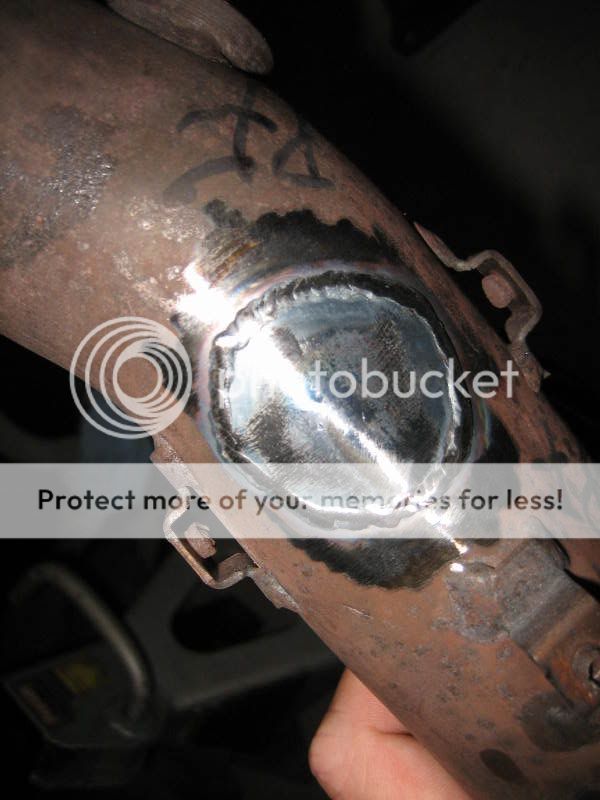

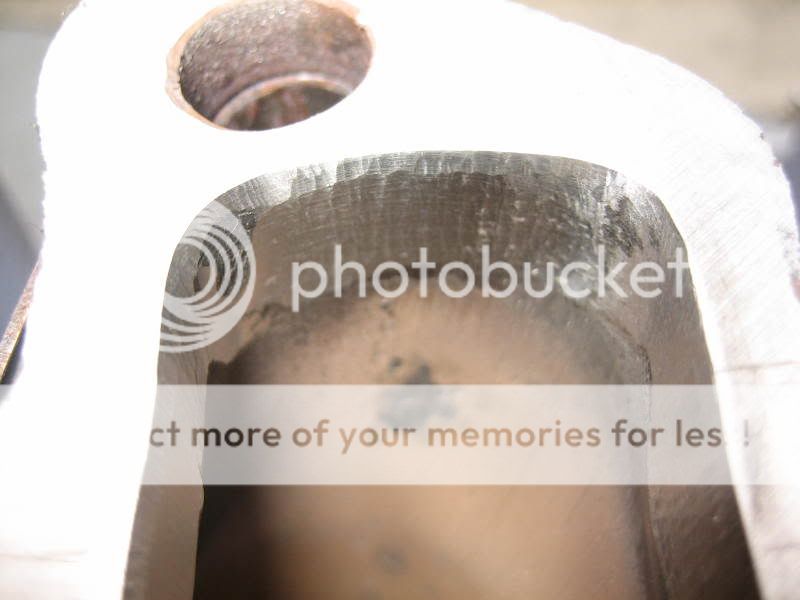

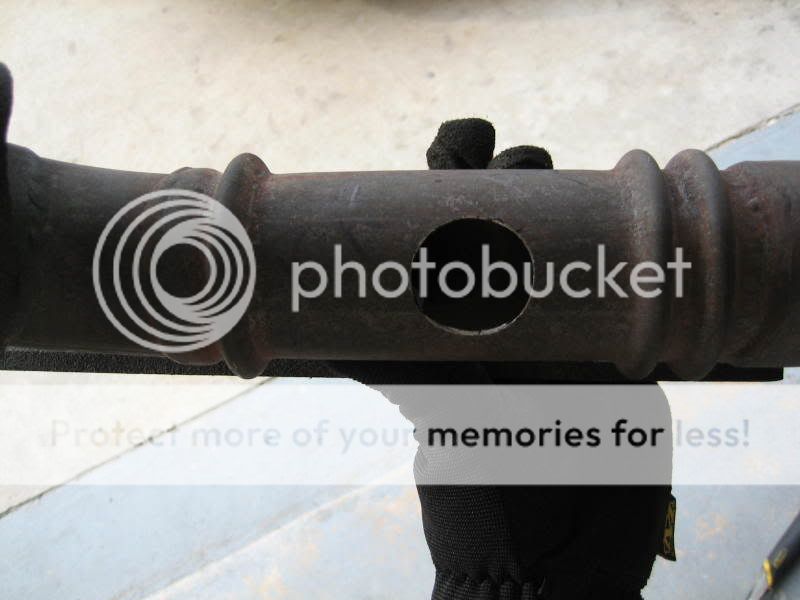

Here is a picture of the hole I drilled for #5.

The hole for #4.

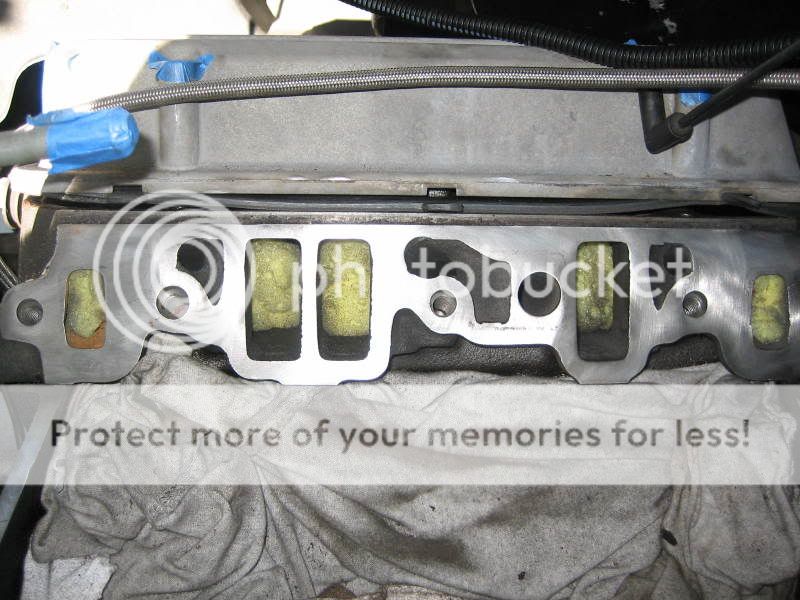

And the hole for #2. I did need to drill out the rivets for the heat shield, but will replace it when it's welded up.

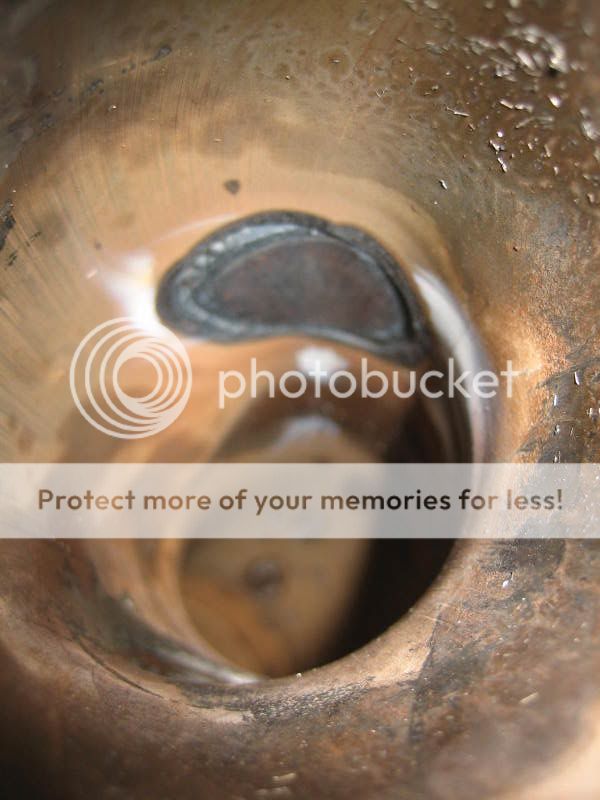

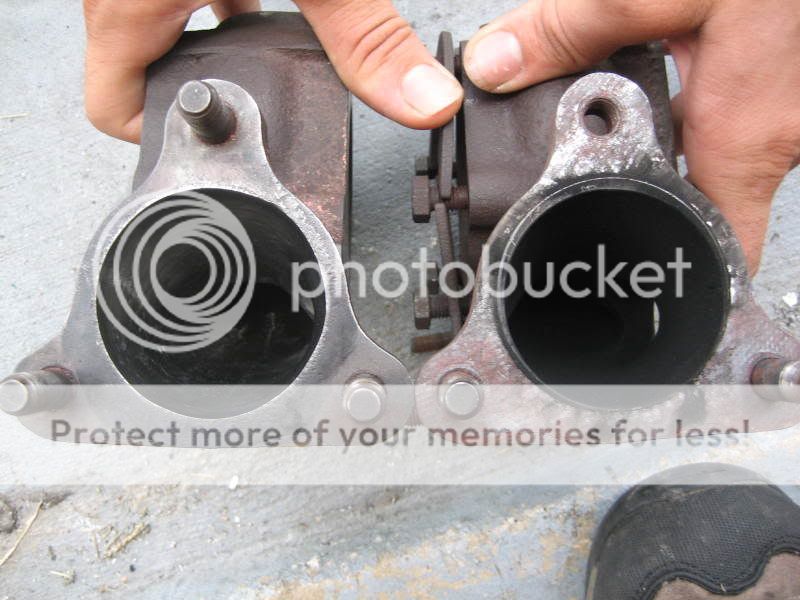

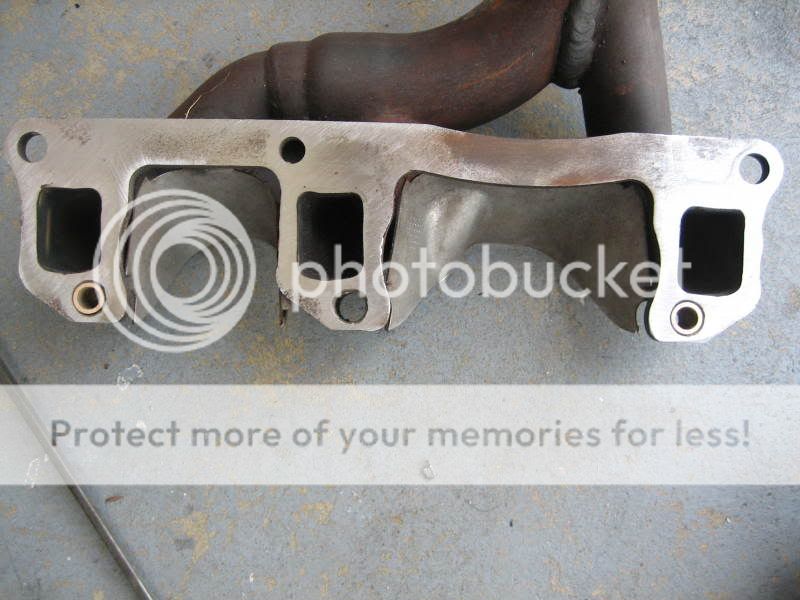

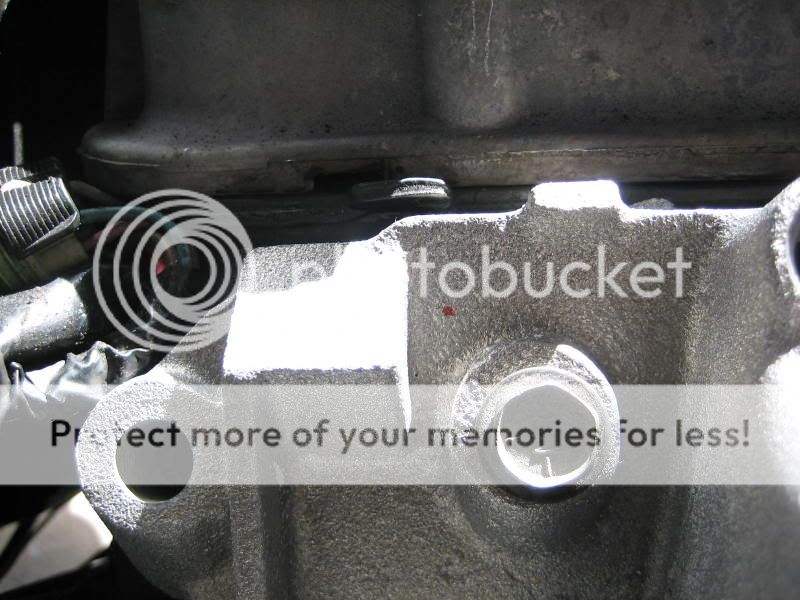

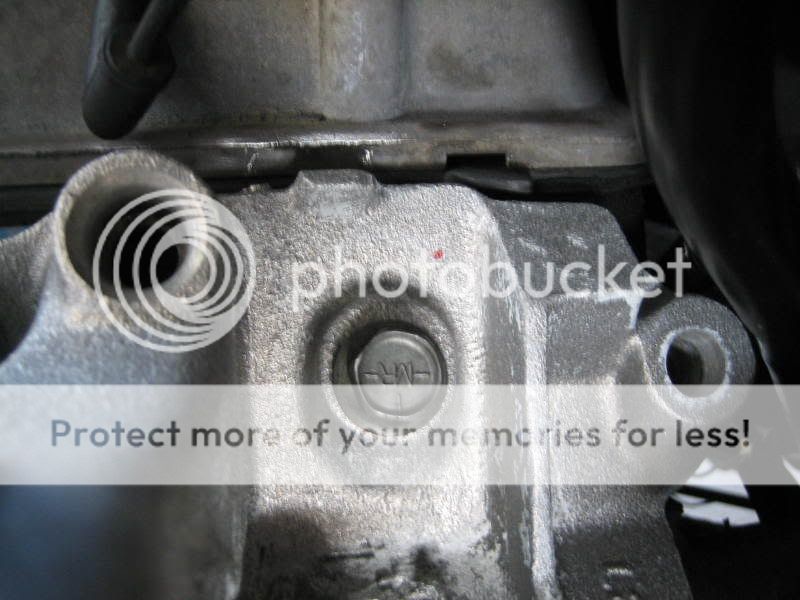

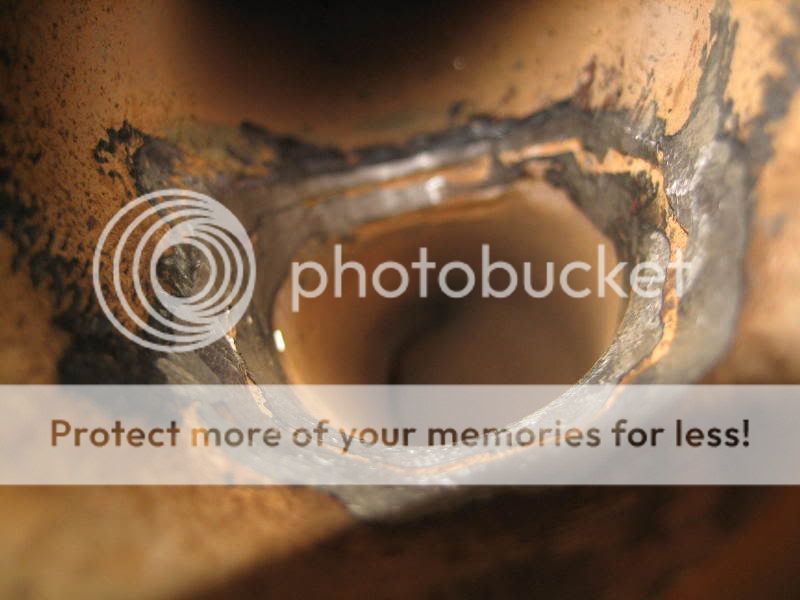

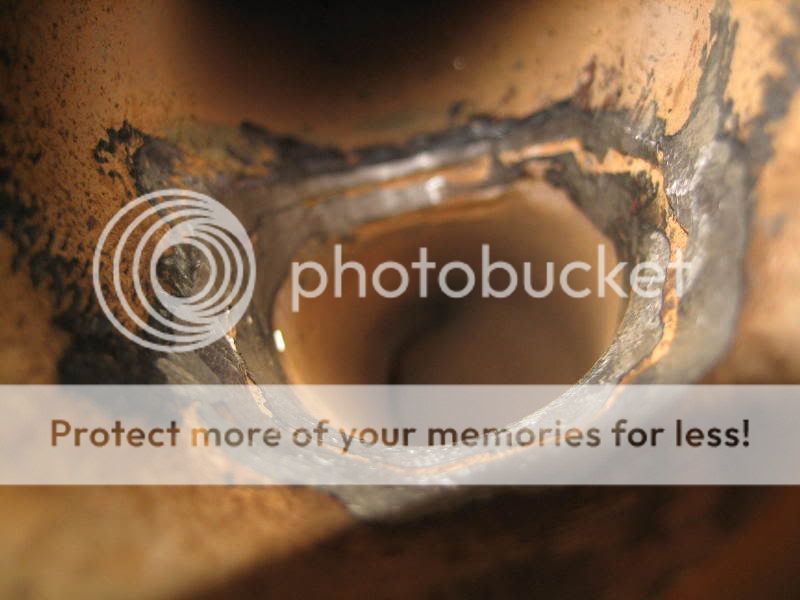

Here are some shots of the primary outlets before porting. Excuse the dark pictures. It's really hard to tell, but some of the overhangs are over and 1/8" deep, which can't help air flow.

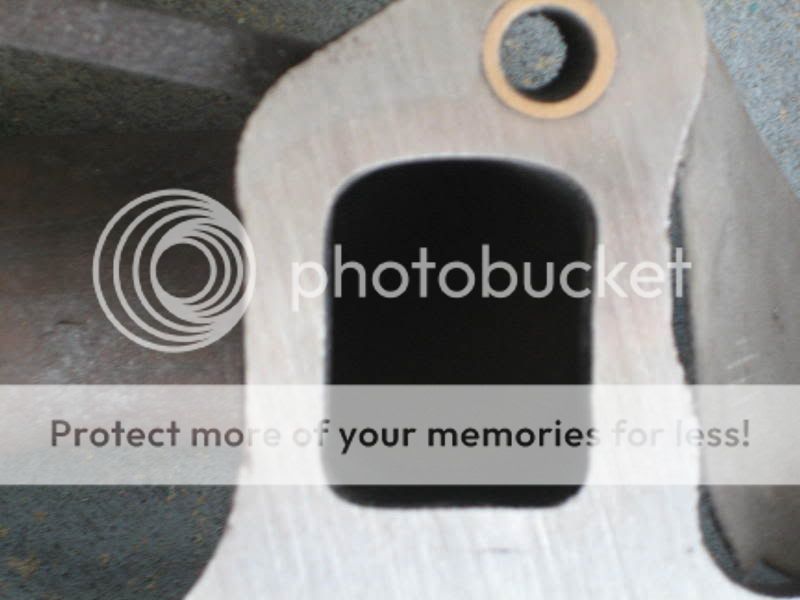

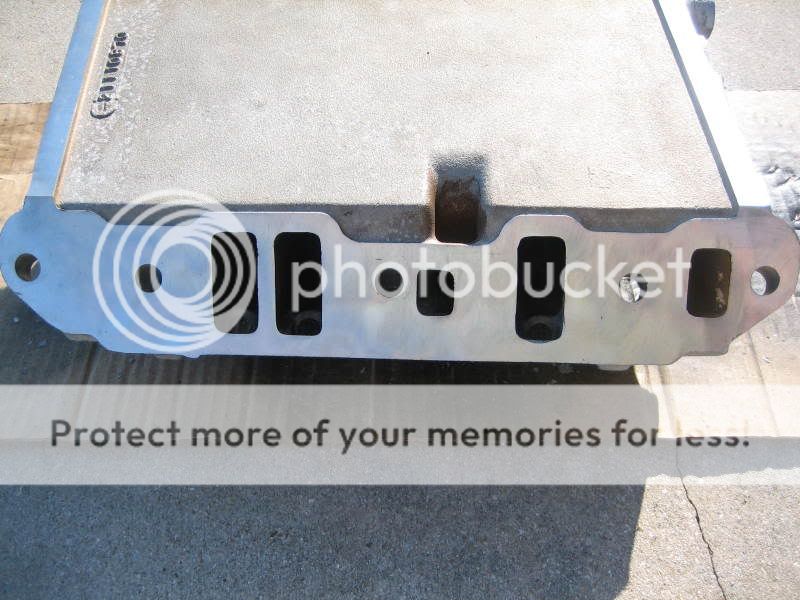

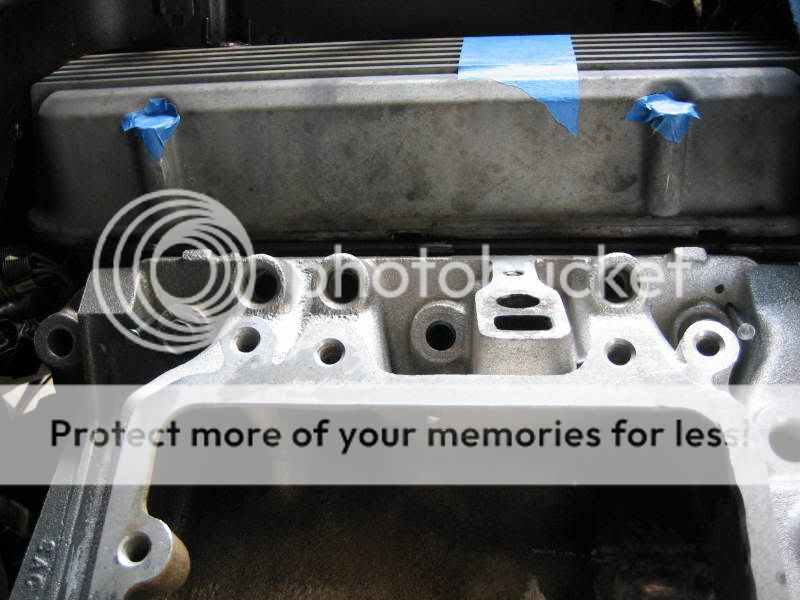

Here are the shots of the completed ports. It looks rough, but to the touch, they are nice and smooth now.

Continued........

Here is a picture of the hole I drilled for #5.

The hole for #4.

And the hole for #2. I did need to drill out the rivets for the heat shield, but will replace it when it's welded up.

Here are some shots of the primary outlets before porting. Excuse the dark pictures. It's really hard to tell, but some of the overhangs are over and 1/8" deep, which can't help air flow.

Here are the shots of the completed ports. It looks rough, but to the touch, they are nice and smooth now.

Continued........